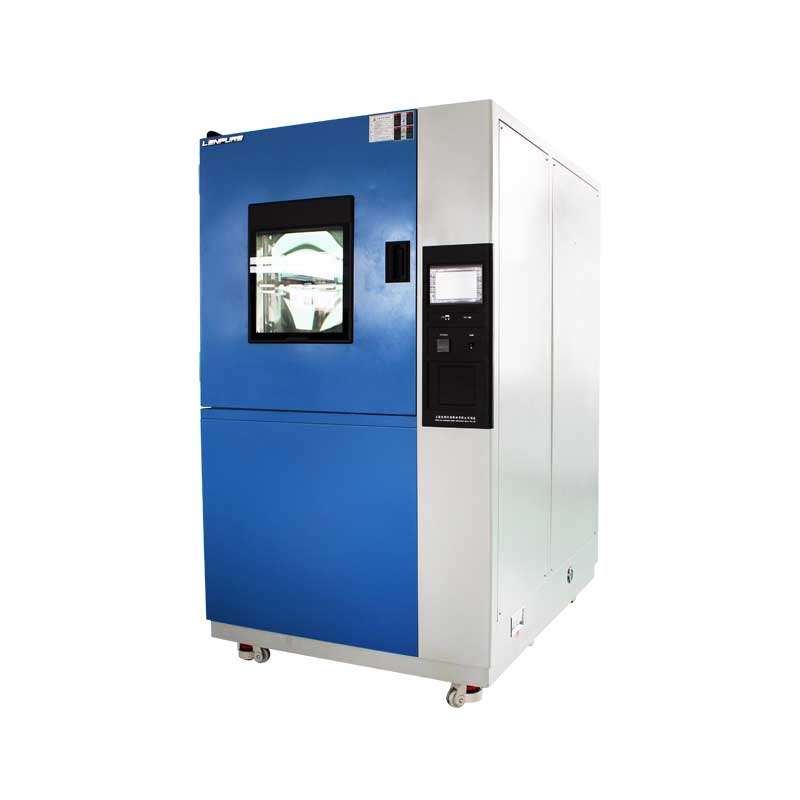

The “Secret Weapon” for Enhancing Industrial Product Quality – Walk-in High and Low Temperature Test Chamber

Author:LINPIN Update Time:2025-07-10 Source:LINPINIn modern industrial production, product quality and reliability are the core of a company's competitiveness. To ensure product performance under various environmental conditions, the walk-in high and low temperature test chamber has become an indispensable tool. By simulating extreme temperature environments, it helps companies conduct rigorous testing and validation during product design, development, and production processes, thereby significantly improving product quality and market competitiveness.

I. Functions of the Walk-in High and Low Temperature Test Chamber

Temperature Screening Test

The walk-in high and low temperature test chamber can simulate high and low-temperature environments, helping to detect product performance under different temperature conditions. Through temperature screening tests, products that may fail under extreme temperatures can be identified, thereby enhancing product reliability and stability.

Full-Temperature Calibration

For precision instruments and equipment that require calibration at multiple temperature points, the walk-in high and low temperature test chamber provides a stable and controllable temperature environment. This full-temperature calibration ensures product accuracy and stability across the entire operating temperature range.

Performance Testing

The device is used to conduct performance tests on various products under extreme temperature environments, including high-temperature and low-temperature environmental tests. Through these tests, companies can evaluate product durability and performance changes, optimizing product design accordingly.

II. Application Fields of the Walk-in High and Low Temperature Test Chamber

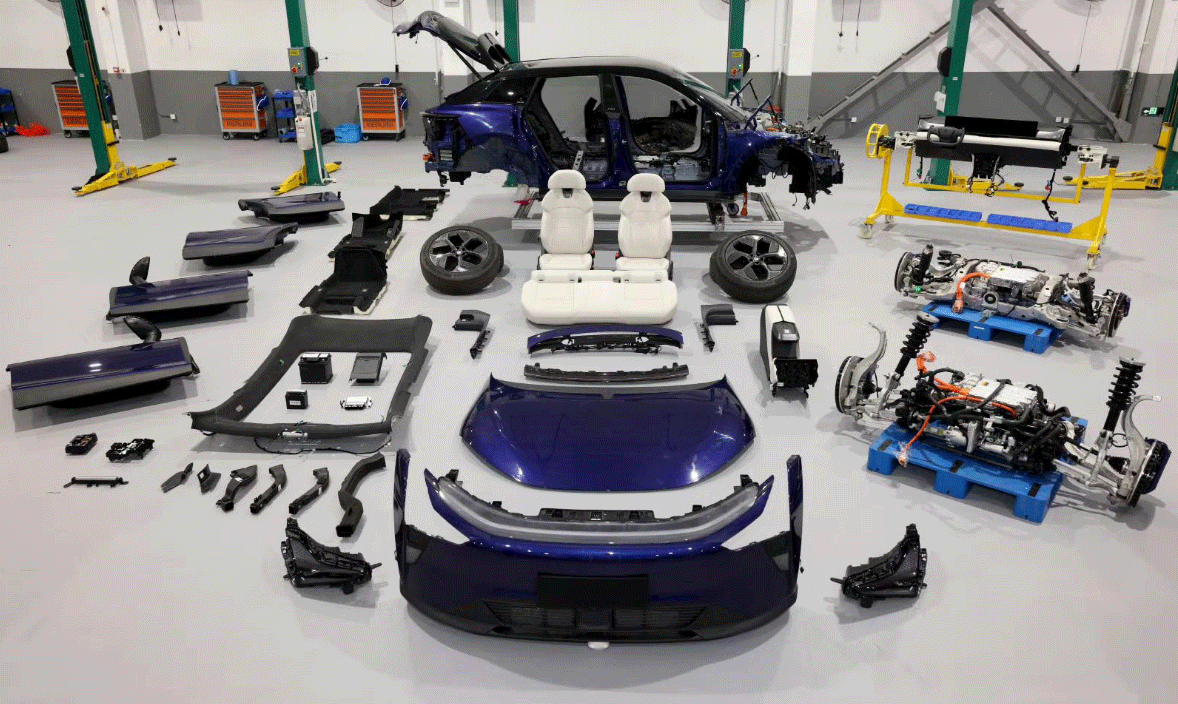

Automotive Industry

In automotive manufacturing, the walk-in high and low temperature test chamber is used to test the performance of entire vehicles or automotive components under different temperature environments. For example, car engines, transmissions, and onboard electronic devices all require testing under high and low temperatures to ensure they function properly under various climatic conditions.

Electronic Product Testing

For electronic products and their components, the walk-in high and low temperature test chamber can predict their durability under drastic temperature changes. This is crucial for ensuring the reliability and stability of electronic products in various usage environments.

Aerospace Sector

Aerospace equipment experiences extreme temperature variations during launch or flight. The walk-in high and low temperature test chamber can simulate these extreme conditions to test the durability and reliability of components.

III. Advantages of the Walk-in High and Low Temperature Test Chamber

Large Capacity Design

The walk-in high and low temperature test chamber features a spacious interior, capable of accommodating large equipment or batch samples for testing, improving flexibility and efficiency.

High-Precision Control

The device employs an advanced temperature control system, enabling precise adjustment of the chamber's temperature and rapid temperature changes, ensuring the accuracy and repeatability of test results.

Safety Protection Measures

The equipment is equipped with multiple safety mechanisms, such as over-temperature protection, power protection, and emergency stop buttons, ensuring the safety of operators and the device.

The walk-in high and low temperature test chamber plays a vital role in modern industrial production. It not only helps companies enhance product quality and reliability but also provides critical data support during the development of new products, offering a strong guarantee for companies to gain a competitive edge in the fierce market.