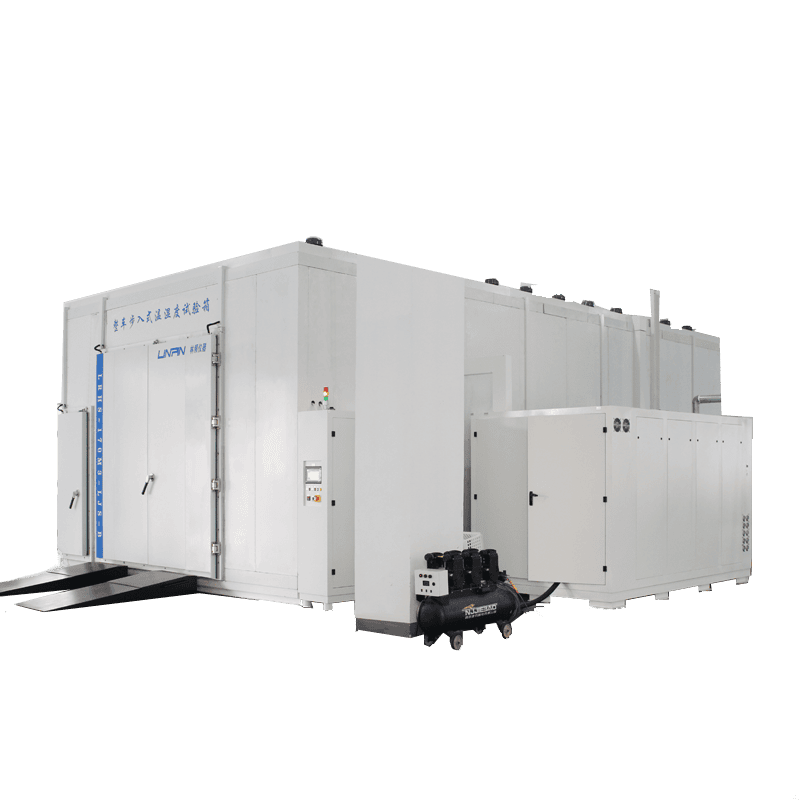

Battery Test Chamber

Product Usage :Battery Test Chamber(New energy battery test chamber) is mainly used for various types of large-scale battery high temperature, low temperature, hot and humid, temperature alternating cycles and other items of the long continuous test

Apply to:Battery Test, High Temperature Test, Low Temperature Test, Temperature Shock Test

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Device model | LRHS-6500-LHF | ||

| Performance | temperature range |

A:-20℃~150℃ B:-40℃~150℃ C:-60℃~150℃ D:-70℃~150℃

|

|||

| temperature uniformity | ≤2℃(no load) | ||||

| temperature fluctuation | ≤±0.5℃(no load) | ||||

| Humidity range | 20%~98%RH | ||||

| Humidity uniformity | ±2.5% RH | ||||

| Humidity fluctuations | ±2% | ||||

| Heating rate range | 1.0~3.0℃/min | ||||

| cooling rate | 0.7~1.0℃/min | ||||

| Time setting range | 1~60000M | ||||

| test hole | Installed on the left side of the machine for use with external test power cords or signal lines | ||||

| viewing window | 210×275mm or 395×395mm (effective field of view) | ||||

| Material | Outer box material | High quality A3 steel plate electrostatic spraying | |||

| Inner box material | High grade stainless steel SUS304 | ||||

| Insulation material | Rigid polyurethane foam + fiberglass | ||||

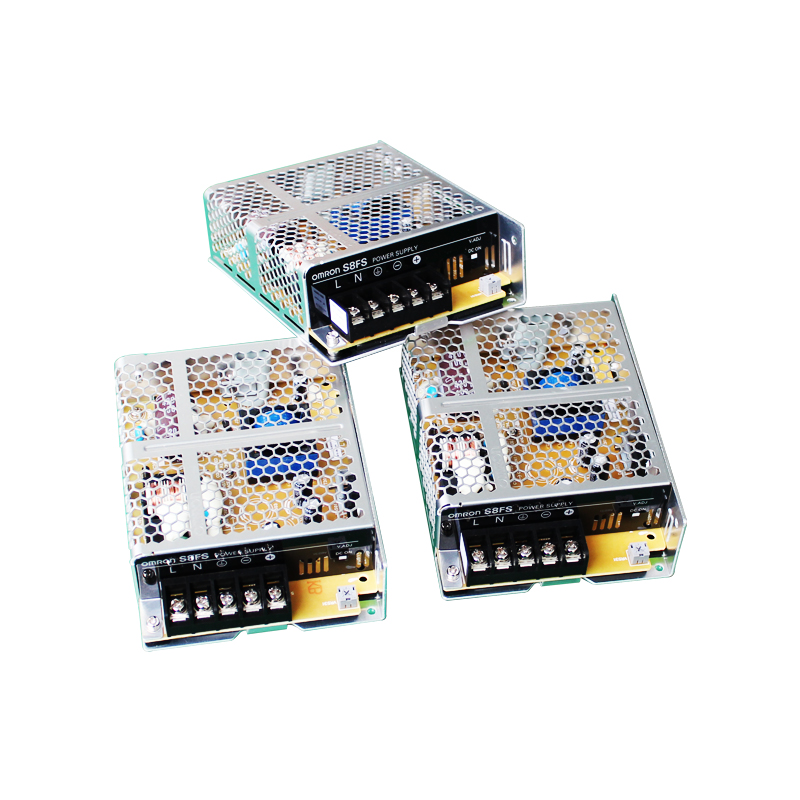

| Basic Specification | Temperature Controller | brand temperature and humidity meter | |||

| Temperature Sensor | PT100 platinum resistance thermometer | ||||

| Refrigeration method | Cascade refrigeration | ||||

| Compressor | French Taican/Germany Bitzer | ||||

| Standard configuration | 1 roll of wet ball gauze, 2 layers of sample rack, equipped with a condensation water collecting tray and drained out of the box | ||||

| safety protection | Sprinkler fire extinguishing device, compressor overpressure and overload, fan motor overheating, complete machine phase loss/reverse phase Over-temperature, overall equipment timing, leakage protection, overload and short-circuit protection |

||||

| voltage | AC380V±10% 50Hz | ||||

| Power rate | 4.0kW/5.5kW/8.5kW/11.5kW/11.5kW | ||||

| Usage environment | 5℃~+28℃ ≤85% RH | ||||

Feature

1. High precision and stability: high precision of temperature and humidity control ensures the accuracy and consistency of test data.

2. Wide adaptability: wide range of temperature and humidity, able to meet the requirements of different types of battery tests, suitable for a wide range of R&D and testing environments.

3. Efficient operation: rapid temperature rise and fall function improves test efficiency and saves time.

4. Long-time continuous operation capability: the long-time setting range is suitable for long-time durability testing.

5. Convenience and ease of operation: test holes and observation windows are designed to make operation more convenient for test monitoring.

6. High-quality materials and workmanship: the use of high-quality materials ensures the durability and reliability of the equipment, suitable for long-term use.

7. Safety: Multiple safety protection measures guarantee the safety during the test and reduce the risk.

8. Flexibility: a variety of power options and temperature range choices, making the equipment more flexible and able to adapt to different sizes and needs of the test.

2. Wide adaptability: wide range of temperature and humidity, able to meet the requirements of different types of battery tests, suitable for a wide range of R&D and testing environments.

3. Efficient operation: rapid temperature rise and fall function improves test efficiency and saves time.

4. Long-time continuous operation capability: the long-time setting range is suitable for long-time durability testing.

5. Convenience and ease of operation: test holes and observation windows are designed to make operation more convenient for test monitoring.

6. High-quality materials and workmanship: the use of high-quality materials ensures the durability and reliability of the equipment, suitable for long-term use.

7. Safety: Multiple safety protection measures guarantee the safety during the test and reduce the risk.

8. Flexibility: a variety of power options and temperature range choices, making the equipment more flexible and able to adapt to different sizes and needs of the test.

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…