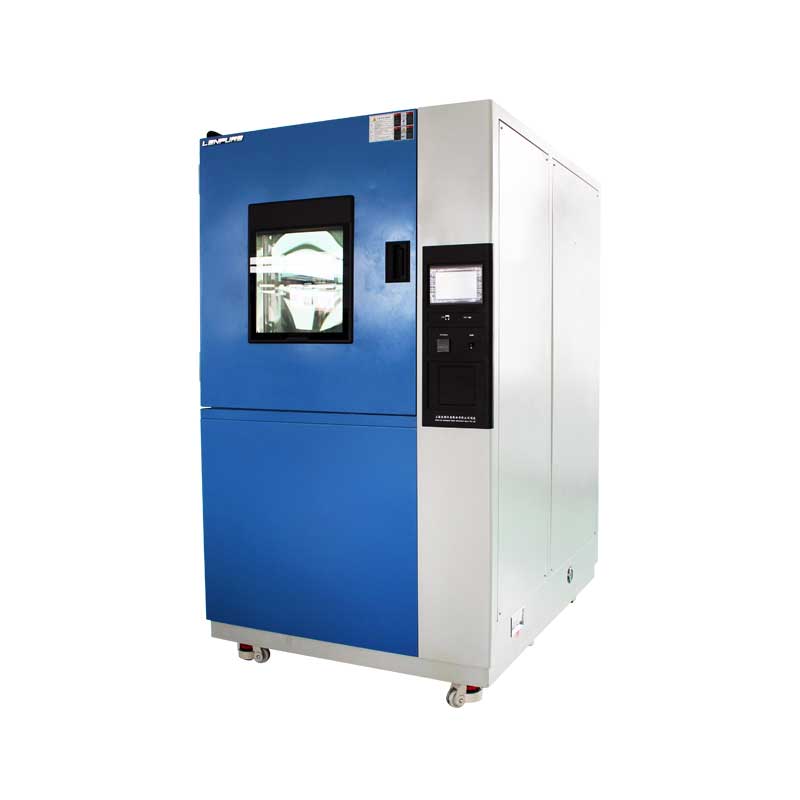

UV Aging Simulation Test Chamber

Product Usage :Photovoltaic module test chamber is mainly used with the photovoltaic industry, ground with crystalline silicon photovoltaic modules, ground with thin film photovoltaic modules and a series of photovoltaic modules for high temperature, low temperature, alternating humidity and heat or constant test of the temperature environment after the change of parameters and performance; or constant humidity and heat test of the temperature environment after the change of parameters and performance. It is specially customised according to the IEC standard and is suitable for schools, factories, military industries, scientific research and other units.

Apply to:Photovoltaic aging test, high temperature test, low temperature test

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Device model | Studio size (D*W*H)mm | Overall dimensions (D*W*H)mm |

| LRHS-672-NGF | 700×800×1200 | 1030×1580×2150 |

| Performance | Light source driver | EPS |

| Effective irradiance area | 800mm×700mm | |

| Distance between light source and test surface | 1000±200mm | |

| Power source | 2000W/light | |

| Number of light sources | 1PCS | |

| Light intensity range | 150~250W/m2 | |

| Spectral range | 280~320nm 320~400nm | |

| UVB/(UVA+UVB) | 5 to 8% | |

| unevenness | ≤10% | |

| UVC content | The ratio of the integrated irradiance in the (250~280) nm wavelength range to the integrated irradiance in the (250~400) nm UVC content wavelength range ≤ 1% | |

| Sample temperature range | 60~70℃ (Customized water-cooling structure for cell stage) | |

| Sample temperature deviation | ≤±2℃ | |

| Cabinet temperature range | 20~80℃ | |

| Box temperature fluctuation | ≤1℃ | |

| Material | Outer box material | 1.2mm cold-rolled steel plate double-sided sprayed |

| Inner box material | 1.0mm thick SUS304 stainless steel, with sunlight-simulating total reflection reflective film mounted on the side wall, dedicated for secondary sealing and optical reflection control | |

| Insulation material | 10mm thickness high quality thermal insulation material | |

| Basic Specification | controller | Siemens PLC module + touch screen |

| Refrigeration method | Air-cooled refrigeration | |

| Compressor | French Taican | |

| heating method | Nickel chromium alloy electric wire heater | |

| light source | The light source warranty time is 2000 hours, and the actual use time is greater than or equal to 3000 hours. | |

| Radiometer | Obody brand | |

| safety protection | Emergency stop button, sample surface temperature is too high, light source system failure alarm, power supply phase loss/undervoltage/overvoltage/leakage protection, fan overload, compressor overvoltage/overheating/overcurrent, heating wire overtemperature protection | |

| voltage | Voltage: 3/N/PE AC 400V±10% 50Hz Rated current: 30A | |

| Power rate | 20.0kW | |

| Usage environment | 10℃~+35℃ ≤75% RH | |

| 3. This technical information is subject to change without prior notice. | ||

Feature

1. High-efficiency light source: high power light source and precise spectral control, improve the effect and reliability of photovoltaic aging test.

2. Stable temperature control system: precise temperature control and water cooling structure ensure the temperature stability of the sample during the test and reduce the error.

3. High-quality materials and structural design: Using high-quality steel plate and stainless steel materials, combined with fully reflective reflective film, provides excellent durability and optical performance.

4. Advanced control system: using Siemens PLC module and touch screen, easy to operate, precise control, improve work efficiency.

5. Reliable safety protection: Multiple safety protection measures ensure the safety of equipment and personnel and reduce the risk of failure.

6. Long service life: adopting high-quality light source and core components to ensure the stable operation of the equipment for a long time and reduce the maintenance cost.

7. Wide range of application: adapt to a variety of environmental conditions and sample requirements, with strong applicability and flexibility.

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…