Photovoltaic freezing test chamber

Product Usage :Photovoltaic freezing walk-in chamber is used to test the material structure or composite material, in the instant by the extremely high temperature and very low temperature of the continuous environment can endure the degree of the specimen can be detected in the shortest possible time due to thermal expansion and contraction of the chemical changes caused by the physical damage.

Apply to:Low temperature test, temperature shock test

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Device model | Studio size (D*W*H)mm | Overall dimensions (D*W*H) mm | |

| LRHS-6500-LHF | 1600×1400×2900 (eight components) | 3900×1750×3300 | |

| Performance | temperature range | -50℃~+120℃ | |||||

| temperature fluctuation | ≤±0.5℃ | ||||||

| temperature uniformity | ≤2.0℃ | ||||||

| temperature deviation | ≤±2.0℃ | ||||||

| Humidity range | 30%~98%RH | ||||||

| Sample temperature control rate | -40℃ to 0℃≥3.33℃/min (linear, full load, powered on) The remaining temperature range ≥1.66℃/min (linear, full load, powered on) | ||||||

| Material | Outer box material | High-quality cold-rolled steel plate, surface spray treatment | |||||

| Inner box material | Stainless steel plate SUS304 | ||||||

| Insulation material | Rigid polyurethane (PU) foam | ||||||

| Basic Specification | controllers | brand temperature and humidity meter, 7-inch high-definition true color LCD touch display | |||||

| Refrigeration Compressors | Bitzer, Germany | ||||||

| Refrigeration method | Double machine cascade refrigeration | ||||||

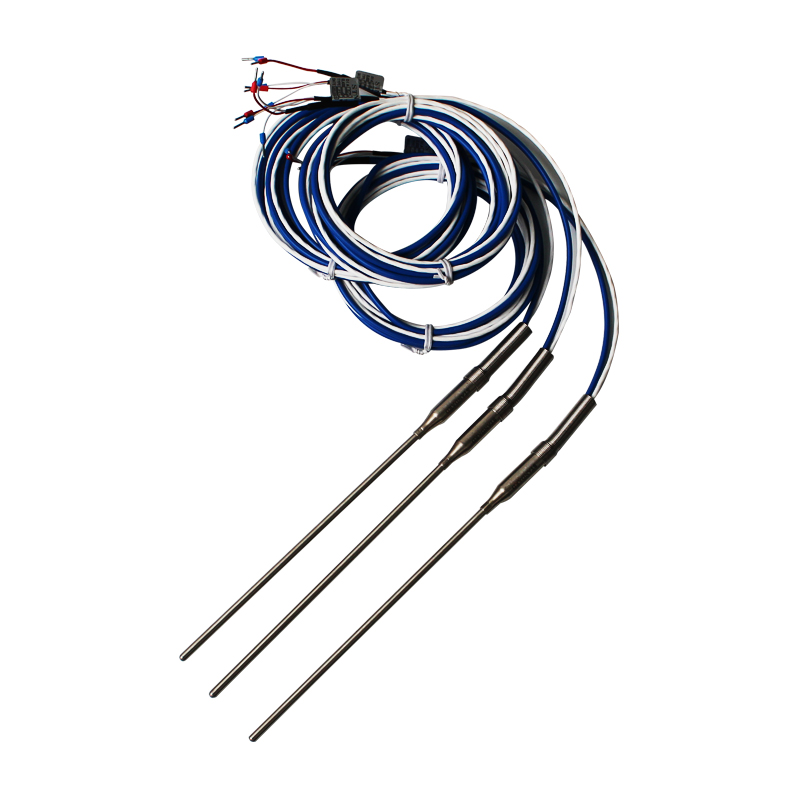

| Temperature and humidity sensor | High-precision Pt100 platinum resistance temperature sensor | ||||||

| safety protection | Compressor overpressure/overload, fan motor overload, overall equipment timing, overtemperature, water shortage, short circuit, phase loss, leakage and other protections | ||||||

| voltage | AC380V±10% 50Hz | ||||||

| total power | 110.0kW | ||||||

| 3. This technical information is subject to change without prior notice. | |||||||

Feature

2. High-precision temperature and humidity control: Ensure the reliability and repeatability of test results through precise temperature and humidity control.

3. Fast response ability: the sample temperature control rate is fast, which improves the testing efficiency and shortens the testing cycle.

4. High-quality material guarantee: the use of high-quality cold-rolled steel plate and stainless steel materials, combined with high-efficiency insulation materials to ensure the durability and stability of the equipment.

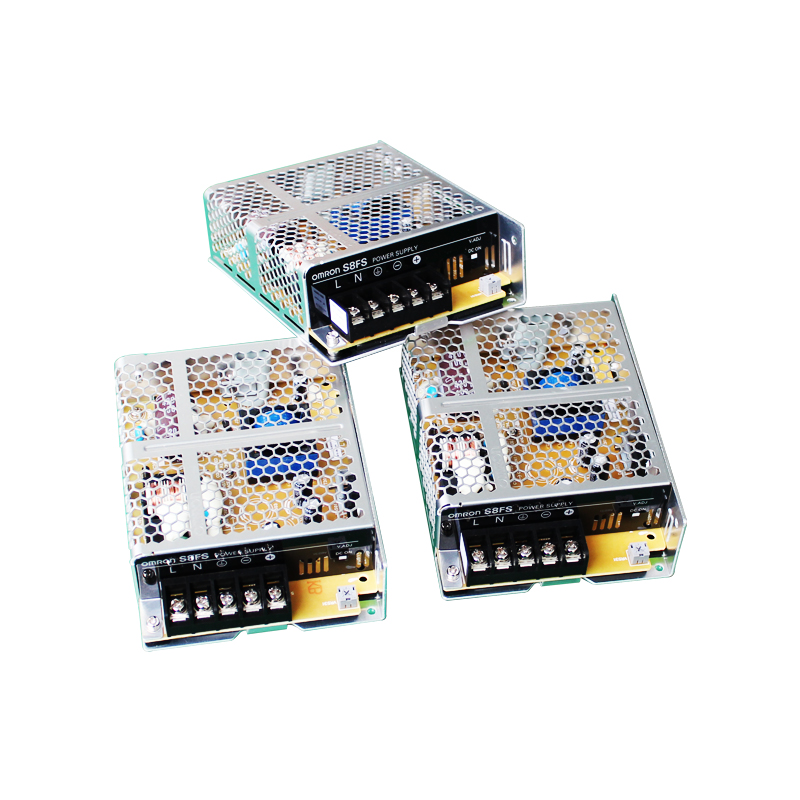

5. advanced control and refrigeration system: high-performance controller and refrigeration system to ensure the stability and efficiency of equipment operation.

6. Comprehensive safety protection: multiple safety protection measures to ensure the safety of equipment and operators and reduce the risk of experiment.

7. High power configuration: 110.0kW total power design, support high intensity and long time testing needs.

8. user-friendly design: high-definition true-colour LCD touch screen, simple and intuitive operation, improve user experience.

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…