Temperature and Humidity Test Chamber

Product Usage :Temperature and Humidity Test Chamber(High and Low Temperature Alternating Humidity Test Chamber) is an essential testing device in aviation, automotive, home appliances, scientific research, and related fields. It is designed to evaluate and determine the parameters and performance of electrical, electronic, and other products or materials after exposure to temperature variations such as high temperature, low temperature, alternating humidity-heat conditions, or constant environmental testing.

Apply to:

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Model | Studio Size(D*W*H)mm | Dimension(D*W*H)mm | |

| LRHS-101B-LJS | 450×450×500 | 1170×950×1530 | |

| LRHS-225B-LJS | 500×600×750 | 1220×1100×1780 | |

| LRHS-504B-LJS | 700×800×900 | 1270×1350×1950 | |

| LRHS-800B-LJS | 800×1000×1000 | 1380×1500×2060 | |

| LRHS-1000B-LJS | 1000×1000×1000 | 1580×1510×2060 | |

| Temperature range | A:-20℃~150℃ B:-40℃~150℃ C:-60℃~150℃ D:-70℃~150℃ |

||||||

| Temperature uniformity | ≤2℃ (unladen) | ||||||

| Temperature fluctuation | ±0.5℃(unladen) | ||||||

| Time Setting Range | 1~60000M | ||||||

| Humidity range | 20%~98% RH | ||||||

| Humidity uniformity | +2% -3% RH | ||||||

| Humidity fluctuation | ±2% | ||||||

| Heating rate | 1.0~3.0℃/min | ||||||

| Cooling rate | 0.7~1.0℃/min | ||||||

| Test hole | Mounted on the left side of the machine for use with external test power or signal cables | ||||||

| Viewing window | 210×275mm / 395×395mm(effective vision) | ||||||

| Outer box material | High quality A3 steel plate electrostatic spraying | ||||||

| Inside box material | Imported high-grade stainless steel SUS304 | ||||||

| Insulation material | Rigid polyurethane foam + glass fiber | ||||||

| Temperature and humidity controller | Adopting Japan “UMC” brand temperature meter | ||||||

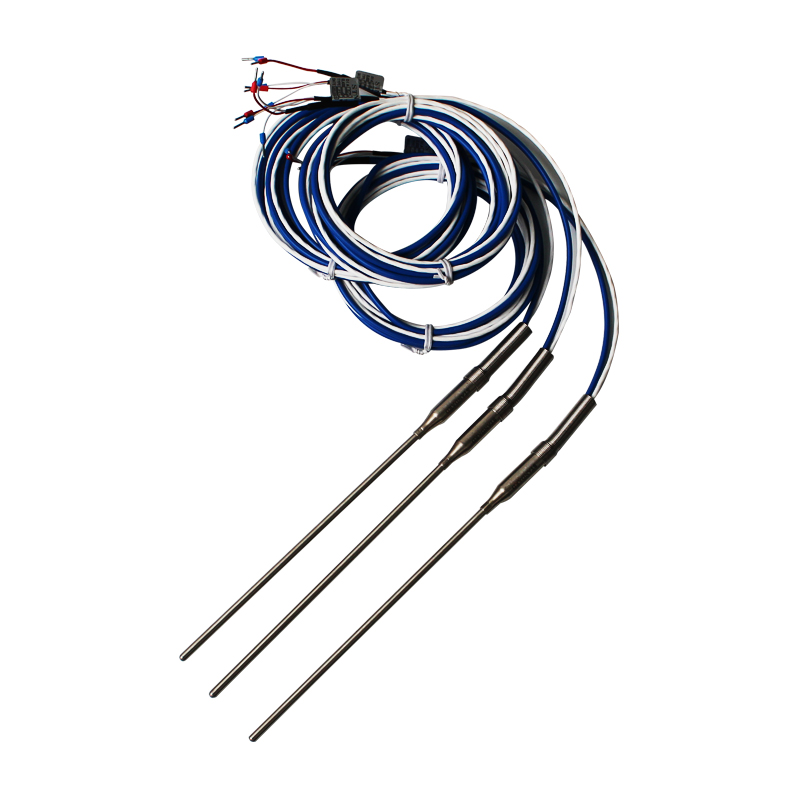

| Temperature and Humidity Sensor | PT100 Platinum resistance thermometer | ||||||

| Cooling method | Single or double cascade refrigeration | ||||||

| Compressor | Tecumseh, France | ||||||

| Standard configuration | 1 roll of wet bulb gauze, 2 sample racks, with condensate catch pan and drain out of the box | ||||||

| Safety | Compressor overpressure overload, over-temperature, fan motor overheating, leakage protection whole machine phase / reverse phase, the whole equipment timing, overload and short circuit protection. | ||||||

| Supply Voltage | AC380V±10% 50Hz | ||||||

| Power | (A) 3.5kW/4.0kW/6.0kW/8.0kW/9.0kW (B) 4.0kW/4.5kW/7.5kW/9.0kW/10.5kW (C) 4.5kW/6.5kW/9.0kW/13.0kW/13.0kW |

||||||

| Operating environment | 5℃~+28℃ ≤85% RH | ||||||

| Note: 1、 the above data are in the use of ambient temperature of 25 ℃ and well ventilated conditions measured 2、Can be customized according to the user’s specific test requirements of the user non-standard Temperature and Humidity Test Chamber etc. 3、This technical information, subject to change without notice |

|||||||

Feature

1. Programmable Touch Screen Controller

2. Custom Sizes Available

3. Running Time Meter

4. Wide Temperature and Humidity Ranges

5. Capable of Handling Extreme Temperature and Humidity

6. High Performance Even Under Load

7. Incandescent Interior Lighting

8. Modular,Robust Reliable Construction

9. Stainless Steel Interior

10. Painted Galvanized Steel Exterior For Long Life

11. Heavy-duty Flooring to Support Vehicles

12. Mechanical Cooling

13. Comprehensive Safety Features

14. Refrigeration Gauges

15. Refrigeration Sound Deadening Package

16. Low or Zero Ozone Depletion Refrigerants

17. All Circuits Fused or Circuit Breaker Protected.

18. All Wiring Numbered or Color Coded

19. Compressor Overload Protection

20. Prefabricated for On-Site Installation

Test standard

MIL-STD-810H:2022、MIL-STD-810G:2008

IEC 60068-2-1:2020、IEC 60068-2-2:2020

IEC 60068-2-78:2022、IEC 60068-3-5:2018

ISO/IEC 17025:2017、IEC 60068-2-14:2020

ASTM E2310-22、ISO 16750-4:2023、EN IEC 61010-1:2021

American Standards:

IEC 60068-3-5:2018

ASTM E2310-22

UL 61010-1:2019

SAE J1455:2020

Chinese Standards:

GJB 150.9A-2009 Damp Heat Test Method

GB/T 2423.1-2008 Test A: Low-Temperature Test Method

GB/T 2423.2-2008 Test B: High-Temperature Test Method

GB/T 2423.3-2016 Test Ca: Constant Damp Heat Test Method

GB/T 2423.4-2008 Test Db: Cyclic Damp Heat Test Method

GB/T 10586-2006 Specification for Damp Heat Test Chambers

GB/T 5170.5-2016 Inspection Methods for Damp Heat Testing Equipment

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…