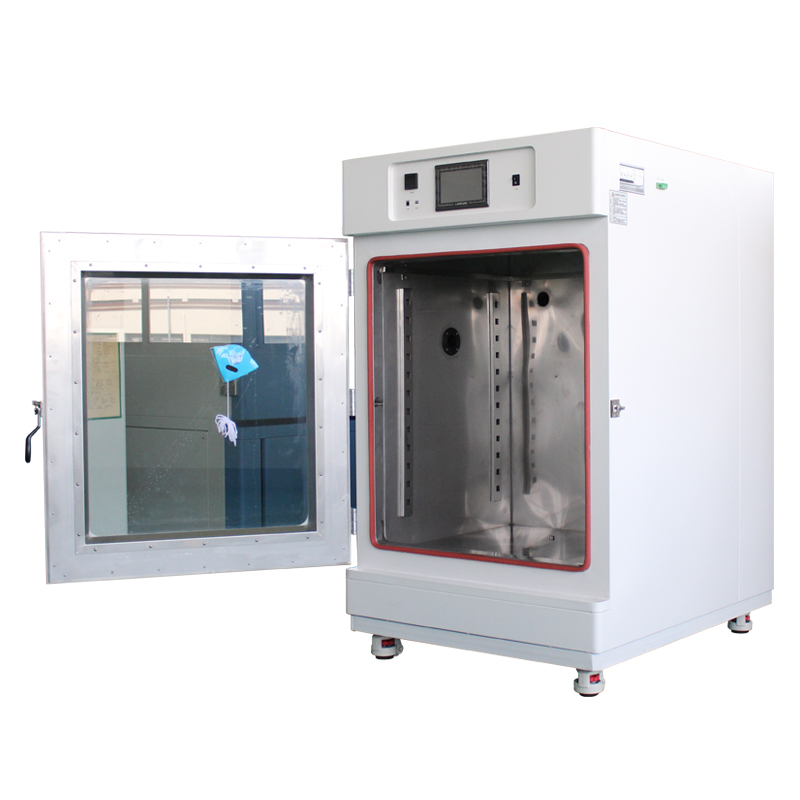

Condensation Water Test Chamber: Ensuring Stability of Chemical Products in High-Humidity Environments

Author:LINPIN Update Time:2025-07-10 Source:LINPINThe condensation water test chamber is a device that simulates high-humidity environments and is widely used for stability testing of chemical products, particularly those exposed to prolonged damp or humid conditions. By controlling temperature and humidity inside the chamber, it replicates conditions similar to humid climates, allowing for the evaluation of chemical products' physical and chemical stability as well as corrosion resistance. Its key functions and application scenarios include:

Key Functions:

- Humidity Control: Uses humidification and condensation systems to simulate different humidity levels, typically above 95% RH.

- Temperature Regulation: Maintains high temperatures (e.g., 40°C to 60°C) to replicate long-term exposure in hot and humid environments.

- Condensation Simulation: Mimics exposure to moisture or rainwater, ensuring long-term stability under such conditions.

- Corrosion Testing: Evaluates surface corrosion reactions, particularly for chemical products, protective coatings, and moisture-resistant packaging materials in extreme humidity.

Applications:

- Chemical Products: Tests the stability of raw materials, formulations, and packaging materials in high-humidity environments, especially those exposed during manufacturing and storage.

- Material Research: Assesses moisture and corrosion resistance of coatings, plastics, and metals.

- Electronics: Evaluates the reliability of electronic components, printed circuit boards (PCBs), and other parts in humid conditions.

- Automotive Industry: Tests the durability of vehicle components (e.g., body panels, engine parts) in high-humidity environments.

- Environmental Reliability Testing: Used in product development, quality control, and final reliability testing before shipment.

Key Testing Parameters:

- Humidity (RH): Simulates varying humidity effects, typically 95%-100% RH.

- Temperature: Ranges from 35°C to 65°C, adjusted based on product requirements.

- Condensation Volume: Controls humidity and temperature variations to generate condensation and observe its impact on products.

Ensuring Chemical Product Stability:

During storage and transportation, chemical products often face challenges such as moisture, humidity, and mold growth. The condensation water test chamber helps identify these issues in advance, ensuring product quality and safety. By subjecting chemical products to prolonged exposure at different humidity and temperature levels, their stability and adaptability in high-humidity environments can be assessed.

In summary, the condensation water test chamber plays a crucial role in guaranteeing the reliability of chemical products, ensuring their stability in high-humidity conditions and ultimately enhancing product quality and safety.