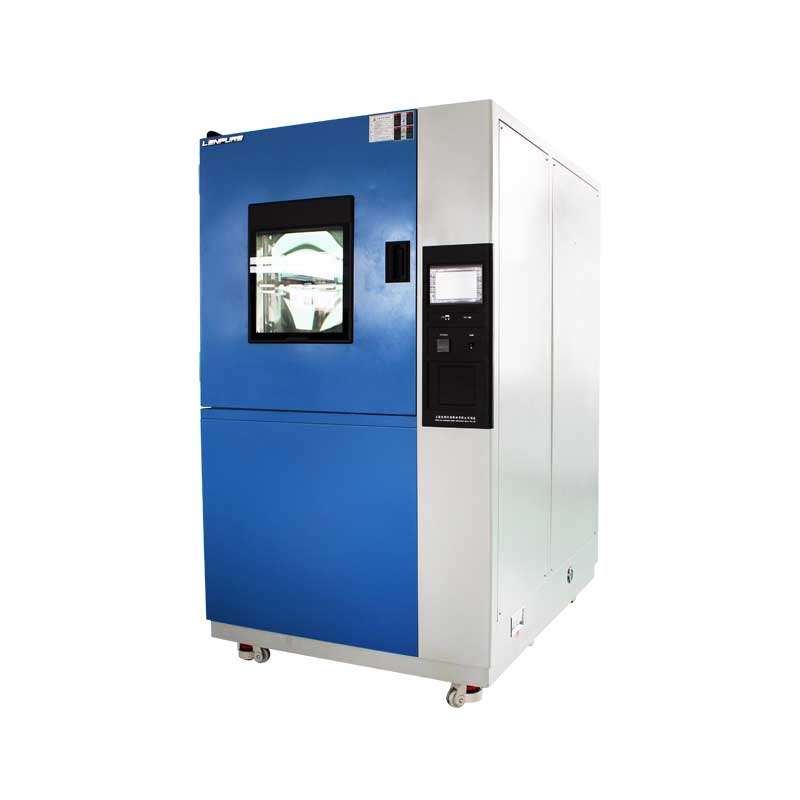

Salt spray constant temperature and humidity test chambers

Product Usage :Salt spray constant temperature and humidity test chambers (Salt Fog Chamber、Corrosion Test Chamber)are used to evaluate the performance indicators of aerospace products, information electronic instruments, materials, electrical and electronic products, and various electronic components under high/low temperature or damp-heat conditions. Salt spray testing applies to protective coatings on parts, electronic elements, and metal materials, as well as to salt-fog corrosion testing of industrial products.

Apply to:

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Model | Studio Size (D*W*H)mm | Dimension(D*W*H)mm | |

| LRHS-504-RYGS | 700×800×900 | Subject to contractual three-view | |

| LRHS-800-RYGS | 800×1000×1000 | ||

| LRHS-1000-RYGS | 1000×1000×1000 | ||

| temperature range | RT+5℃~60℃ | ||||||

| Saturated drum temperature | RT+10℃~60℃ | ||||||

| Temperature uniformity | ≤2℃ | ||||||

| Temperature fluctuation | ±0.5℃ | ||||||

| Salt spray deposition | 1~2ml/80 cm².h(16-hour average) | ||||||

| Spraying method | Wall-mounted spray pattern | ||||||

| temperature range | RT+10℃~100℃ | ||||||

| Humidity range | 85%~98%RH | ||||||

| Temperature uniformity | ±2℃ (at no load) | ||||||

| Temperature fluctuation | ±0.5℃ (at no load) | ||||||

| Humidity fluctuation | ±1% | ||||||

| temperature deviation | ±2℃ | ||||||

| Humidity Deviation | ±3% | ||||||

| temperature range | RT+10℃~200℃ | ||||||

| Temperature uniformity | ±2℃ (at no load) | ||||||

| Temperature fluctuation | ±0.5℃ (at no load) | ||||||

| temperature deviation | ±2℃ | ||||||

| Case Material | High quality 316 stainless steel | ||||||

| Studio Materials | Imported high-grade stainless steel SUS304 | ||||||

| Air-saturated drums | Imported high-grade stainless steel SUS304 | ||||||

| Pressurized Air Hose Material | High quality rubber hose | ||||||

| Other pipelines | Thickened Fluorosilicone Rubber Tubing | ||||||

| Temperature Controller | Imported “UEC” brand temperature and humidity meter | ||||||

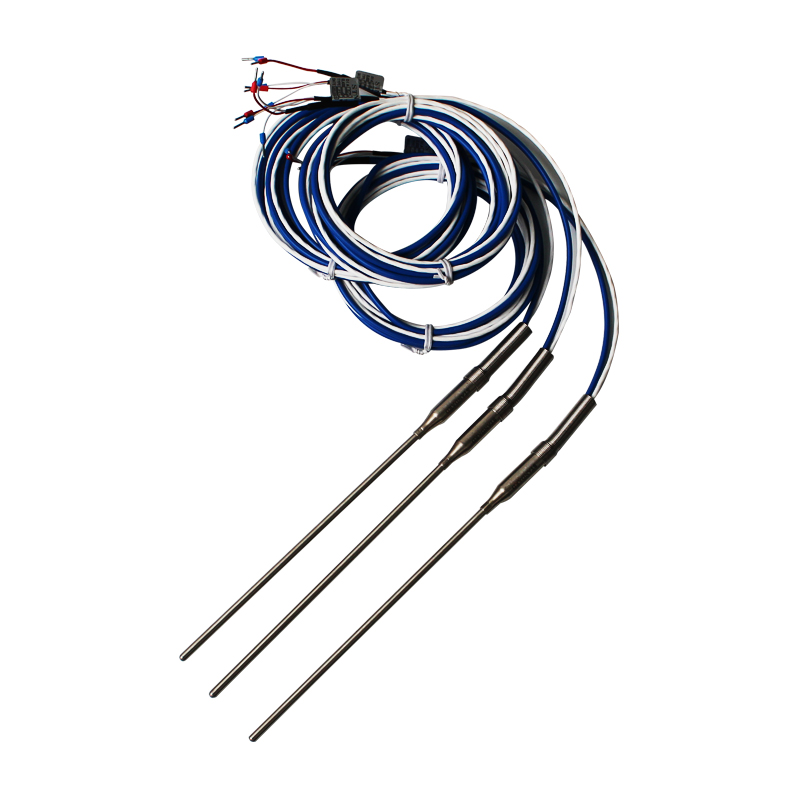

| temperature sensor | PT100 platinum resistance temperature measurement body | ||||||

| heater | Titanium Heating Tube | ||||||

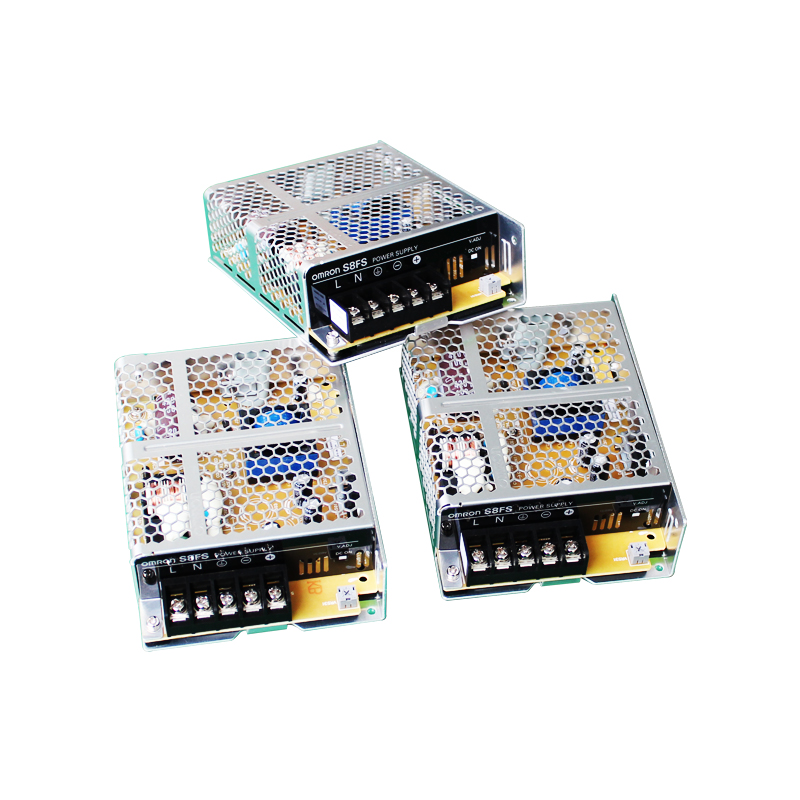

| interrupter | Schneider miniature circuit breakers (to prevent short circuits in control circuits) | ||||||

| standard configuration | V-shaped sample holder, round bar, nozzle, funnel, measuring cylinder, mist exhaust pipe | ||||||

| security protection | Over-temperature, overall equipment under-phase/reverse phase, overall equipment timing Quick fog discharge indication, end of test, low water level protection, electric leakage and short circuit |

||||||

| Supply Voltage | AC380V±10% 50Hz | ||||||

| Power | 10.0kW | 13.5kW | 16.0kW | ||||

| operating environment | 5℃~+28℃ ≤85% RH | ||||||

| Note: 1、 the test data are used in the ambient temperature of 25 ℃ and well ventilated conditions measured 2、The above parameters are for reference only, and can be customized according to user-specific test parameters. 3、This technical information, subject to change without notice |

|||||||

Feature

1. Imported reinforced hard PP plates with smooth and flat surface

2. Imported transparent impact-resistant plates as observe window

3. All pipe is anti-corrosion can be used 15years .

4. Adopt water seal method to prevent leakage of salt spray.

5. With air pressure cylinder for convenient operation.

6. Independent heating system , fast speed , temperature and humidity are evenly distributed

7. Equipped with automatic demisting device

8. Fault alarm and resolution remind function

9. Power failure protection function

10. Self-diagnosis function

11. Calendar timing function

12. Tri-color Indicator and EMO (Emergency-off Switch) available

Test standard

MIL-STD-202 “DEPARTMENT OF DEFENSE TEST METHOD STANDARD ELECTRONIC AND ELECTRICAL COMPONENT PARTS “

ISO 9227:2012、ISO 9227:2017、ASTM B117-23、JIS Z 2371:2015、IEC 60068-3-5:2018

ISO/IEC 17025、IEC 60068-2-11:2021

American Standards:

ASTM-B117 “Standard Practice for Operating Salt Spray (Fog) Apparatus”

ASTM-B368 “Standard Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)”

American Electronics

EIA-364-26 “Salt Spray Testing of Electrical Connectors”

Chinese Standards:

GB/T 2423.17 “Environmental testing for electric and electronic products – Part 2: Test methods – Test Ka: Salt mist”

GB/T 10125 “Corrosion tests in artificial atmospheres — Salt spray tests”

GB/T 1771 “Paints and varnishes – Determination of resistance to neutral salt spray(fog)”

GJB150 “Environmental Test Methods for Military Equipment”

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…