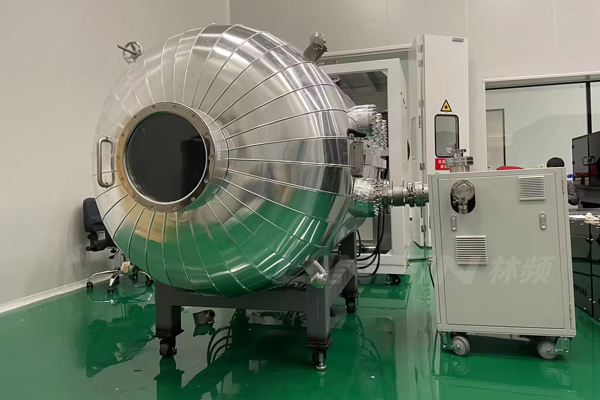

Thermal Vacuum Test Chamber: Providing Stable and Controllable Testing Conditions for Your

Author:LINPIN Update Time:2025-07-09 Source:LINPINThe thermal vacuum test chamber is a device capable of delivering stable and controllable testing conditions, playing a vital role in product development. Below are the advantages of thermal vacuum test chambers in the R&D process:

-

Simulating Extreme Environmental Conditions

Thermal vacuum test chambers can replicate high-temperature and vacuum environments, such as those encountered in aerospace, automotive, and other industries. They expose products to high temperatures and low-pressure conditions to evaluate their performance and reliability. -

Accelerated Product Aging Testing

High-temperature and vacuum conditions accelerate the aging process of products, helping to uncover potential issues and material durability limits. By conducting aging tests in a thermal vacuum test chamber, you can identify and resolve possible failures in advance, thereby improving product quality and reliability.

-

Precise Temperature and Vacuum Control

Thermal vacuum test chambers are equipped with advanced temperature and vacuum control systems, enabling precise regulation of testing conditions. You can set the desired temperature and pressure ranges while using sensors and instruments to monitor and record environmental parameters for accurate data. -

Support for Various Materials and Product Testing

Thermal vacuum test chambers are adaptable to different types of materials and product tests. Whether metals, plastics, electronic components, or other materials, they can all be tested under thermal vacuum conditions to assess their performance and reliability. -

Enhanced R&D Efficiency

Using a thermal vacuum test chamber allows you to complete multiple test cycles in a shorter time. This helps accelerate the product development cycle, improve efficiency, and enable earlier detection and resolution of issues, thereby reducing development costs and time.

Thermal vacuum test chambers provide stable and controllable testing conditions for product R&D, helping enterprises evaluate product performance and reliability under extreme environments. They accelerate aging tests, boost R&D efficiency, and support the development of higher-quality, more reliable products. Choosing a thermal vacuum test chamber as an R&D tool will bring significant advantages and success to your development process!