How Do Spacecraft Use Thermal Vacuum Chambers for Testing?

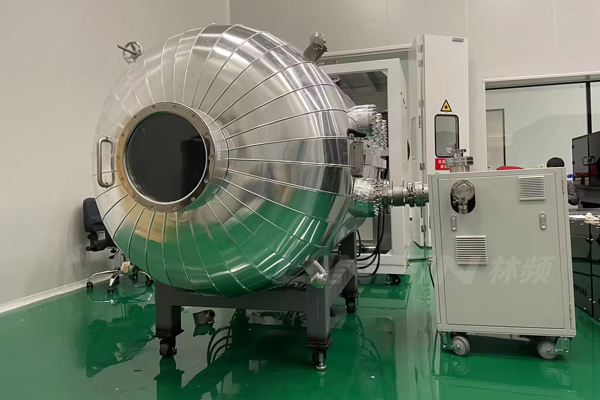

Author:LINPIN Update Time:2025-05-19 Source:LINPINIn the development and manufacturing of spacecraft, ensuring that equipment can operate reliably in the harsh conditions of space is a critical challenge for aerospace engineers. The thermal vacuum chamber, a core facility that simulates the temperature and vacuum conditions of the space environment, serves as a key tool for verifying spacecraft performance and structural reliability.

The Role of Thermal Vacuum Chambers

In the near-zero-pressure environment of space, spacecraft experience extreme temperature fluctuations, shifting rapidly from extreme cold to intense heat. Thermal vacuum chambers accurately replicate these conditions by creating a vacuum and controlling temperature, allowing ground-based simulation of the pressure and thermal variations encountered in space. This enables scientific evaluation of a spacecraft's heat resistance, sealing integrity, and electronic system stability.

How Spacecraft Are Tested in Thermal Vacuum Chambers

-

Sample Preparation and Installation

The spacecraft or its critical components are mounted inside the chamber's test platform, ensuring all connections and support structures are secure and equipped with sensor interfaces for monitoring. -

Vacuum Pumping Process

The vacuum pump system is activated to gradually reduce the chamber's internal pressure to near-space vacuum levels (typically as low as 10⁻⁶ Pa), simulating the low-pressure conditions of space. -

Temperature Control and Cycling

Using built-in heaters and cooling systems, the chamber adjusts temperatures according to preset programs, cycling between ultra-low and high temperatures to simulate the thermal transitions experienced by spacecraft when moving between sunlight and shadow. -

Data Collection and Monitoring

Real-time monitoring of key spacecraft system parameters is conducted via sensors, assessing the performance of mechanical, electronic, and material components under vacuum and extreme temperatures. -

Fault Detection and Improvement

Test data is analyzed to identify potential defects, providing crucial insights for design optimization and ensuring the spacecraft's safety and reliability post-launch.

The Critical Value of Thermal Vacuum Chambers

- Validating Equipment Reliability: Helps detect and eliminate potential failure risks in complex environments before launch.

- Enhancing Launch Success Rates: Significantly reduces in-orbit anomalies and failures, ensuring mission success.

- Reducing R&D Costs: Ground-based testing minimizes the need for rework and repairs, shortening development cycles.

As a cornerstone of spacecraft quality assurance, thermal vacuum chambers provide robust technical support for ensuring spacecraft adaptability to extreme environments. Through rigorous and scientific thermal vacuum testing, they propel the aerospace industry toward higher and farther-reaching space exploration ambitions.