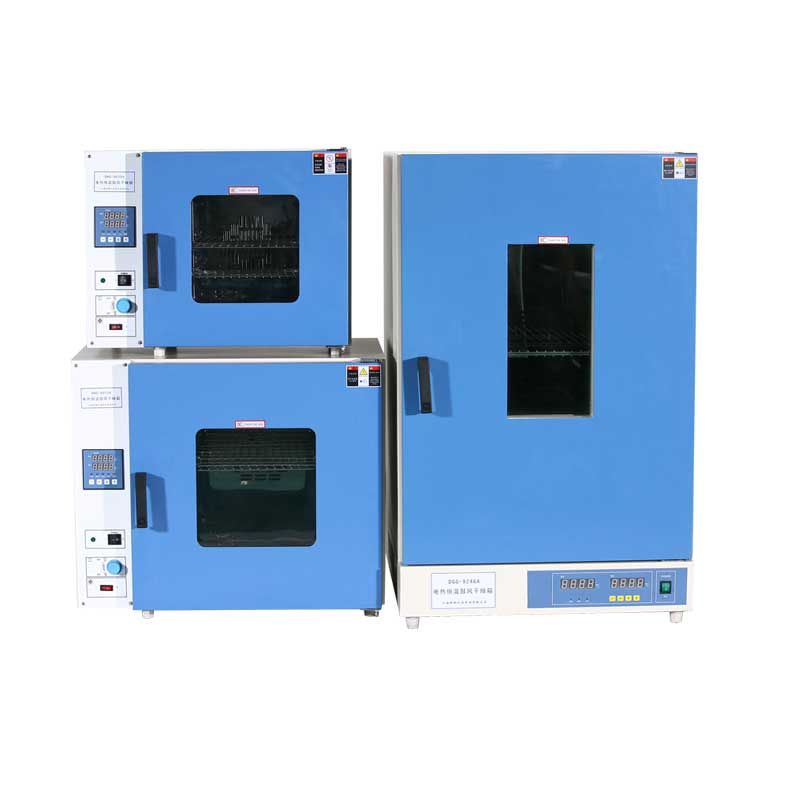

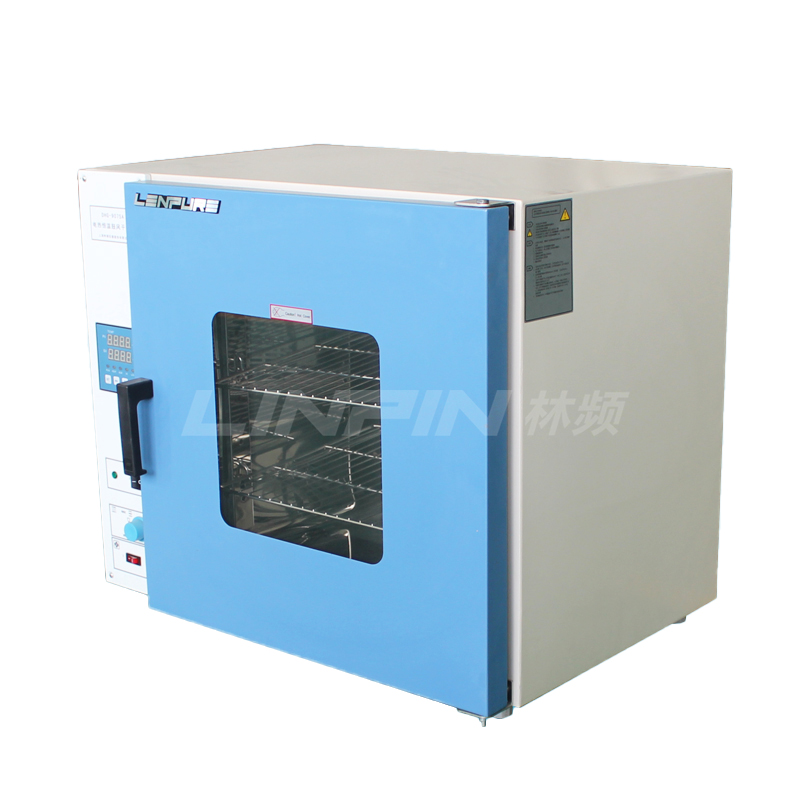

Blast Drying Oven

Product Usage :Blast drying oven(Forced Air Drying Oven), blast oven is aviation, automotive, home appliances, scientific research and other fields of essential test equipment for testing and determining electrical, electronic and other products and materials for high-temperature test temperature environment after the change of parameters and performance.

Apply to:Forced Air Drying Ovens

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| name | Device model | Studio size | Dimensions | power | notes |

| Desktop blast drying oven | DHG-9023A | 340×270×320 | 630×510×490 | 870W | RT+10℃~250℃ |

| DHG-9053A | 420×340×350 | 710×590×520 | 1120W | ||

| DHG-9070A | 450×335×450 | 740×590×630 | 1570W | ||

| DHG-9140A | 550×385×550 | 840×640×730 | 2070W | ||

| DHG-9240A | 600×500×750 | 885×780×940 | 2470W | ||

| DHG-9035A | 340×270×320 | 630×510×490 | 870W | RT+10℃~300℃ | |

| DHG-9055A | 420×340×350 | 710×590×520 | 1120W | ||

| DHG-9075A | 450×335×450 | 740×590×630 | 1570W | ||

| DHG-9145A | 550×385×550 | 840×640×730 | 2070W | ||

| DHG-9245A | 600×500×750 | 885×780×940 | 2470W | ||

| Vertical blast drying oven | DGG-9030A | 330×280×350 | 445×490×700 | 550W | RT+10℃~200℃ |

| DGG-9070A | 400×400×450 | 545×620×800 | 940W | ||

| DGG-9140A | 450×520×550 | 640×750×900 | 1390W | ||

| DGG-9240A | 500×570×750 | 690×785×1100 | 1890W | ||

| DGG-9420A | 600×550×1300 | 840×770×1800 | 3370W | ||

| DGG-9620A | 800×600×1300 | 1035×825×1800 | 3970W | ||

| DGG-9036A | 300×300×350 | 445×450×710 | 550W | RT+10℃~300℃ | |

| DGG-9076A | 400×400×450 | 550×550×800 | 940W | ||

| DGG-9146A | 450×550×550 | 640×700×900 | 1390W | ||

| DGG-9246A | 500×600×750 | 690×730×1100 | 1890W | ||

| DGG-9426A | 600×550×1300 | 770×710×1750 | 3370W | ||

| DGG-9626A | 800×600×1300 | 970×760×1750 | 3970W |

| Performance | temperature range | RT+10℃~200℃/ RT+10℃~250℃/RT+10℃~300℃ | |||||

| control precision | 1% (full scale) | ||||||

| Constant temperature fluctuation | ±1℃ | ||||||

| Temperature resolution | ±0.1℃ | ||||||

| Heating rate | 2.0℃~8.0℃/min | ||||||

| Timing range | 1-9999M | ||||||

| Material | Outer box material | High quality A3 steel plate electrostatic spraying | |||||

| Inner box material | Imported high-grade stainless steel SUS304 | ||||||

| Insulation material | High density fiberglass wool | ||||||

| Observation window | Multilayer hollow tempered glass | ||||||

| temperature sensor | PT100 platinum resistance thermometer | ||||||

| temperature circulation system | Air-conditioning fan imported from the United States | ||||||

| Standard configuration | Sample rack 2 layers/3 layers/4 layers | ||||||

| safety protection | Short circuit protection, overall equipment phase loss/reverse phase (380V power supply only) | ||||||

| voltage | AC220V±10% 50Hz or AC380V±10% 50Hz | ||||||

| Usage environment | 5℃~+28℃ ≤85% RH | ||||||

| 1. This technical information is subject to change without prior notice. | |||||||

Feature

The main features of the Blast Drying Oven:

1. Wide temperature range Temperature range: RT+10℃~200℃, RT+10℃~250℃, RT+10℃~300℃, adapting to different drying and experimental needs.

2. High precision control

3. Fast temperature rise

4. High quality material

5. Comprehensive safety protection

6. Adapt to a variety of power supply: power supply voltage: AC220V±10% 50Hz or AC380V±10% 50Hz, applicable to different power supply conditions.

1. Wide temperature range Temperature range: RT+10℃~200℃, RT+10℃~250℃, RT+10℃~300℃, adapting to different drying and experimental needs.

2. High precision control

3. Fast temperature rise

4. High quality material

5. Comprehensive safety protection

6. Adapt to a variety of power supply: power supply voltage: AC220V±10% 50Hz or AC380V±10% 50Hz, applicable to different power supply conditions.

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…