Usage Standards and Specifications for Ozone Aging Test Chambers

Author:LINPIN Update Time:2025-05-19 Source:LINPINIn modern industrial fields, particularly in materials science and product testing, ozone aging test chambers serve as critical equipment for evaluating the oxidation resistance and stability of materials. To ensure the accuracy and reliability of test results, the use of ozone aging test chambers must adhere to relevant standards and specifications. Below, we outline the fundamental usage standards and specifications for operating ozone aging test chambers to help you better understand and apply this equipment.

I. Purpose and Significance of Ozone Aging Test Chambers

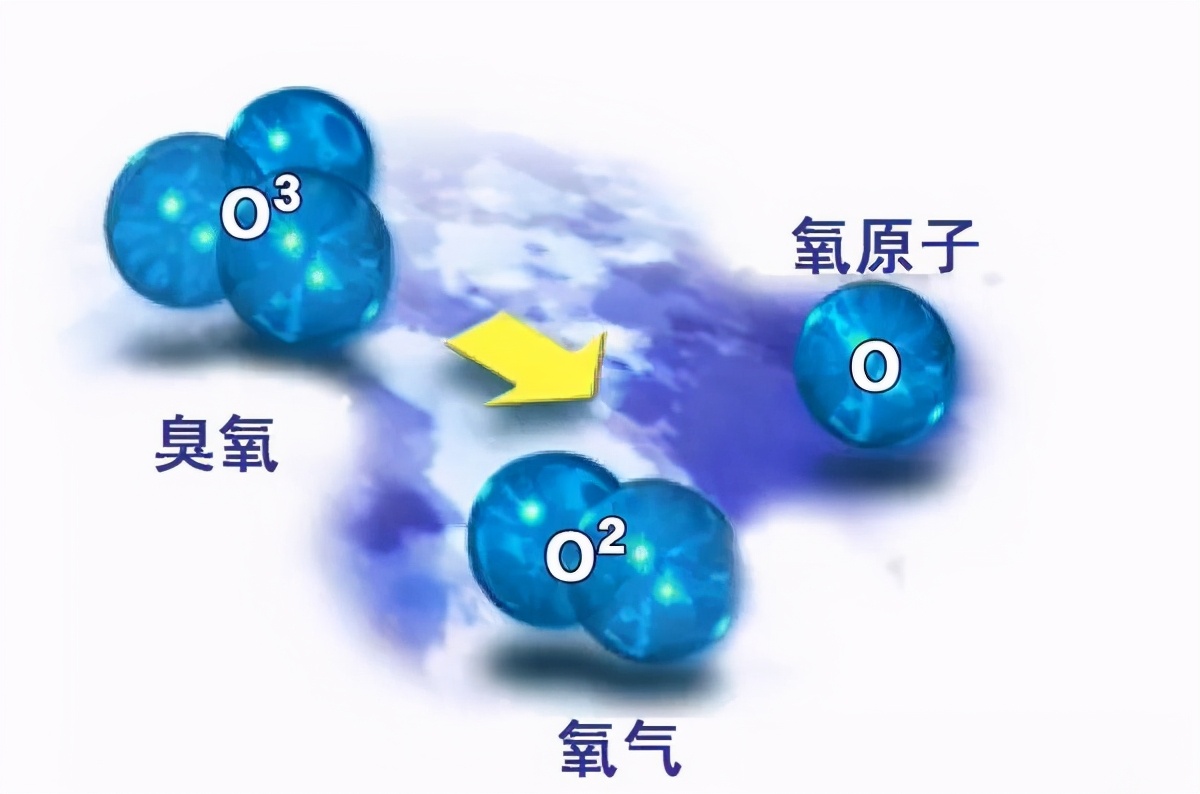

Ozone possesses strong oxidizing properties, which can easily cause rubber materials to crack or degrade. Ozone aging test chambers simulate the aging process of materials in an ozone environment, enabling businesses to predict the service life and reliability of products under real-world conditions. These chambers are indispensable for new material development and quality control.

II. Usage Specifications and Requirements

-

Equipment Installation and Environmental Requirements

Before using an ozone aging test chamber, ensure it is installed in a well-ventilated environment with stable temperature and controlled humidity. The interior of the chamber should remain clean to prevent dust or debris from affecting test accuracy. -

Equipment Calibration and Maintenance

Regular calibration of the ozone aging test chamber is necessary to ensure measurement accuracy. It is generally recommended to conduct comprehensive maintenance and inspections every six months, including ozone concentration calibration and checks on temperature and humidity sensors. -

Operational Guidelines

- Sample Preparation: Samples should undergo pre-treatment (cleaning, drying, etc.) under specified environmental conditions to ensure a contamination-free surface.

- Test Conditions: Ozone concentration, temperature, and humidity settings must comply with relevant standards. For example, typical ozone concentrations range from 50 ppb to 1000 ppb, test temperatures are usually between 25°C and 60°C, and humidity can be adjusted as needed.

- Test Duration: The testing period depends on the material type and application environment, typically ranging from several hours to hundreds of hours.

-

Data Recording and Analysis

During testing, parameters such as temperature, humidity, and ozone concentration should be recorded periodically for subsequent analysis. After testing, inspect the samples for changes in appearance and physical properties, and compile a complete test report. -

Safety Measures

Ozone is a strong oxidizer, so safety precautions must be taken when using the test chamber to avoid direct inhalation. Ensure proper ventilation in the testing area to prevent hazardous ozone buildup.

III. Key Usage Standards

The most authoritative standards for ozone aging test chambers include:

-

GB/T 7762-2006 "Rubber—Test Method for Ozone Aging"

This standard specifies test conditions, equipment requirements, and procedures for ozone aging tests, serving as a fundamental reference in China's rubber industry. -

ISO 1431-1 "Rubber, Vulcanized or Thermoplastic—Resistance to Ozone Cracking—Part 1: Static and Dynamic Strain Testing"

An internationally recognized standard emphasizing control over ozone concentration, temperature, and stress conditions. -

ASTM D1149-18 "Standard Test Methods for Rubber Deterioration—Cracking in an Ozone Controlled Environment"

A standard by the American Society for Testing and Materials (ASTM), applicable to evaluating the ozone resistance of various rubber products.

Mastering and strictly adhering to the usage standards and specifications for ozone aging test chambers is essential for ensuring the scientific validity and reliability of material oxidation resistance testing. Whether in research institutions or industrial manufacturing, selecting compliant equipment and following standardized procedures is key to maintaining a competitive edge in the market.