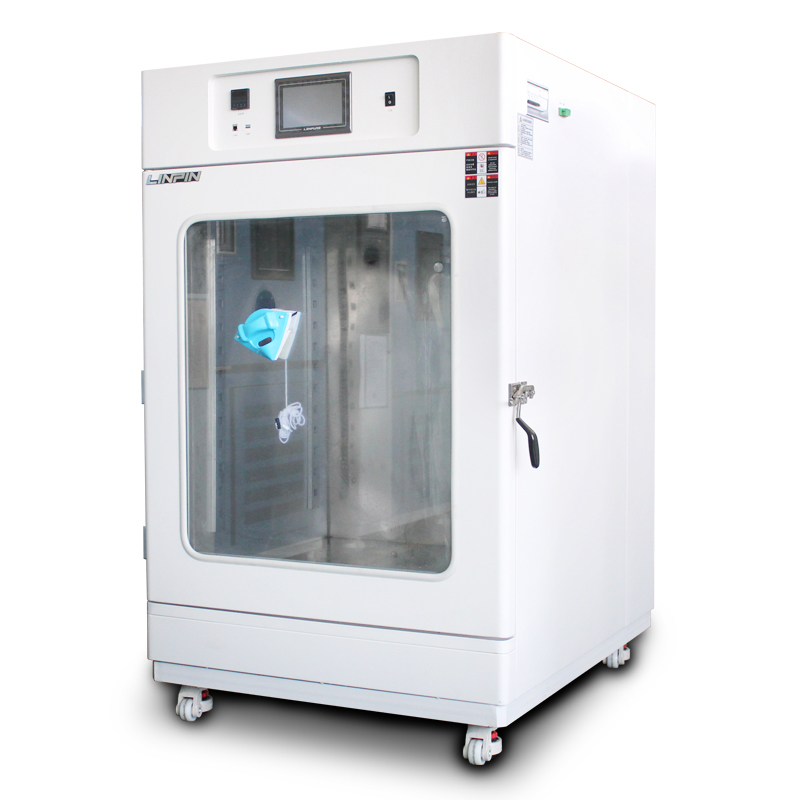

High and Low Temperature Impact Test Chamber

Product Usage :High and Low Temperature Impact Test Chamber(Temperature composite impact test chamber), also known as composite temperature shock testing equipment, is used for environmental testing or reliability stress screening of materials, components, assemblies, parts, and instruments in fields such as aviation, aerospace, automotive, shipbuilding, military, information technology, and electronics. It provides simulated environmental conditions including high temperature and low temperature, and can perform tests such as temperature shock testing, high/low temperature storage testing, temperature cycling testing, and temperature variation testing.

Apply to:

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Main parameter | Studio size | 1000×1000×1000(D*W*H)mm | |||||

| outline dimension | 3400×2000×2300(D*W*H)mm | ||||||

| Impact temperature range | -55℃~85℃ | ||||||

| Pre-cooling Temperature Range of the Cold Room | -75℃~0℃ | ||||||

| Cooling time | 20℃~-75℃≤60min | ||||||

| Recovery condition | High temperature exposure temperature:≤85℃,Exposure time:≤30min Low temperature exposure temperature:≤-55℃,Exposure time:≤30min |

||||||

| Temperature recovery time | ≤5min | ||||||

| Temperature fluctuation | ≤±0.5℃ | ||||||

| Temperature deviation | ≤±2℃(no load) | ||||||

| Temperature uniformity | ≤2℃(no load) | ||||||

| Outer box material | High-quality A3 steel plate electrostatic spraying | ||||||

| Inner box material | Imported high-grade stainless steel SUS304 | ||||||

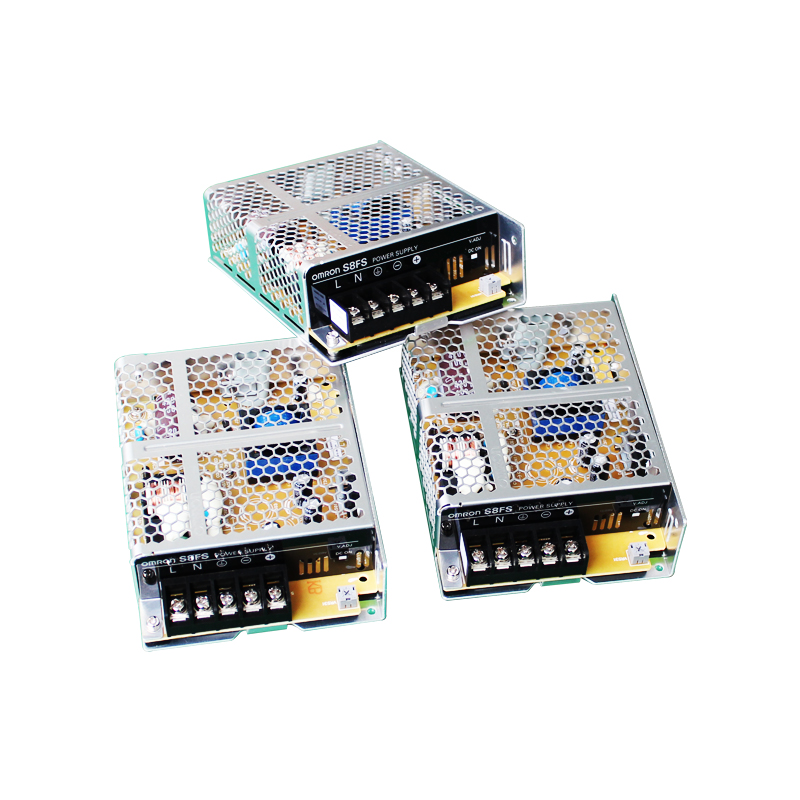

| controller | Imported “Excellent and Easy Control” brand temperature instrument | ||||||

| Power supply voltage | AC380V±10% 50Hz | ||||||

| Note: 1. The test data are all measured when the ambient temperature is 25℃ and the ventilation is good. 2. The above parameters are for reference only and can be customized according to the specific test parameters of users. 3. This technical information is subject to change without prior notice. |

|||||||

Feature

1. Programmable Touch Screen Controller

2. Custom Sizes Available

3. Running Time Meter

4. Capable of Handling Extreme Temperature

5. High Performance Even Under Load

6. Incandescent Interior Lighting

7. Modular,Robust Reliable Construction

8. Stainless Steel Interior

9. Painted Galvanized Steel Exterior For Long Life

10. Heavy-duty Flooring to Support Vehicles

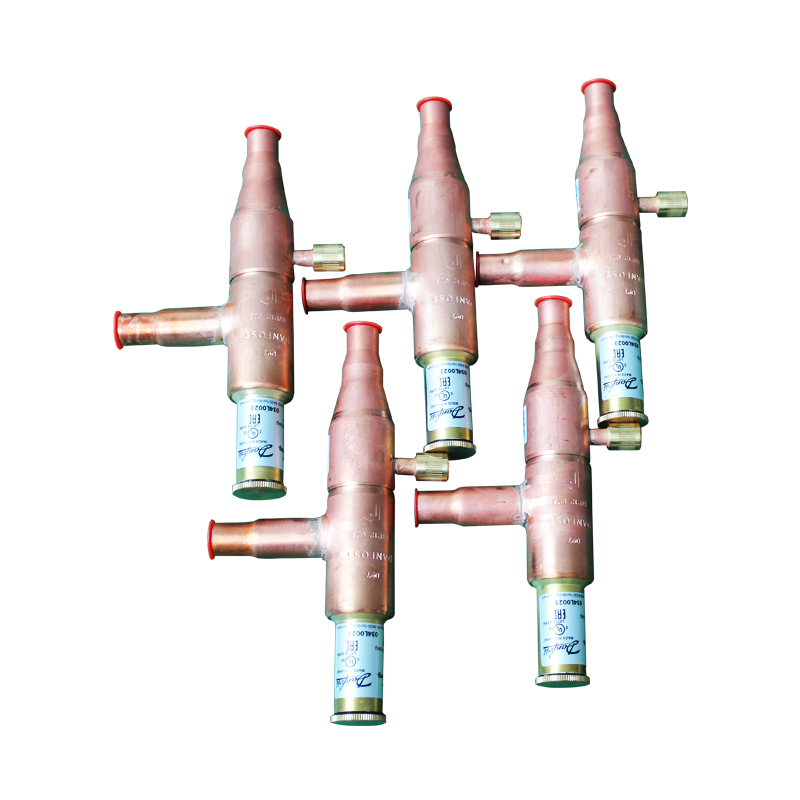

11. Mechanical Cooling

12. Comprehensive Safety Features

13. Refrigeration Gauges

14. Refrigeration Sound Deadening Package

15. All Circuits Fused or Circuit Breaker Protected.

16. All Wiring Numbered or Color Coded

17. Compressor Overload Protection

18. Prefabricated for On-Site Installation

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…