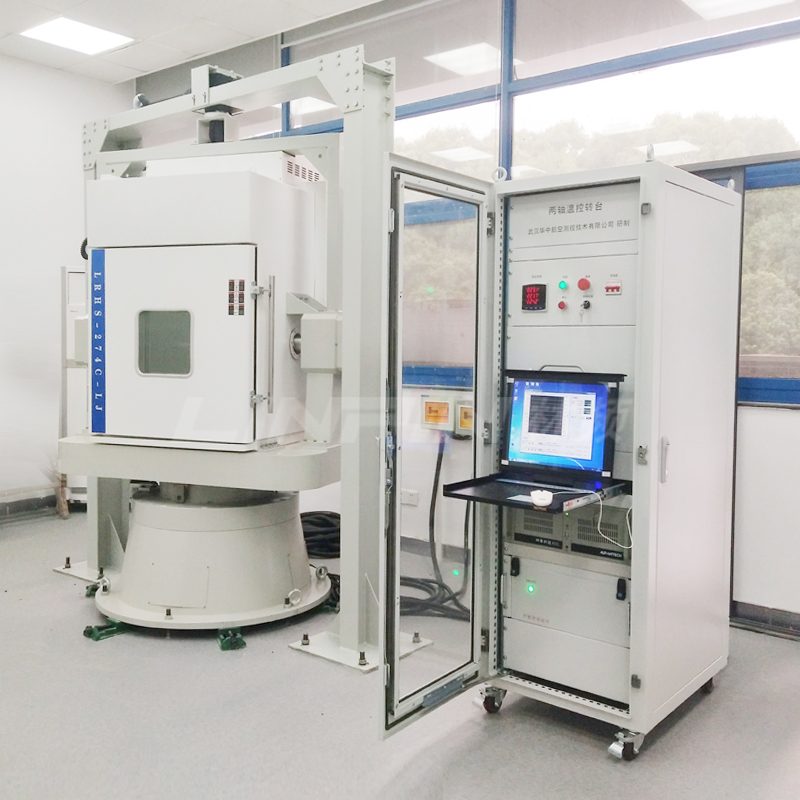

Salt Spray Corrosion Test Chamber: Simulating High-Salt Environments to Validate Product Durability

Author:LINPIN Update Time:2025-09-04 Source:LINPINCorrosion remains one of the most significant challenges in material science and industrial manufacturing, particularly for products exposed to harsh environments such as marine, automotive, or aerospace applications. The salt spray corrosion test chamber serves as a critical tool for evaluating the protective capabilities of coatings, platings, and materials under accelerated corrosive conditions. By replicating high-salt atmospheres, this equipment enables manufacturers to predict long-term performance and identify potential weaknesses before products reach the field.

Principles of Salt Spray Testing

Salt spray testing, standardized by methods such as ASTM B117 and ISO 9227, subjects specimens to a controlled saline mist environment. The chamber generates a fine aerosol of sodium chloride (NaCl) solution, typically at concentrations of 5%, to simulate coastal or de-icing salt exposure. Temperature and humidity are maintained within strict parameters (e.g., 35°C ± 2°C and >95% relative humidity) to ensure consistent corrosion kinetics.

The mechanism of corrosion in these tests follows electrochemical principles, where the saline solution acts as an electrolyte, facilitating oxidation reactions on metallic surfaces. The test duration varies from 24 hours to several weeks, depending on the expected service environment and material specifications.

Key Applications Across Industries

-

Automotive Sector

Vehicle components, including brake systems, fasteners, and electronic enclosures, must withstand road salt and humidity. Salt spray testing validates the efficacy of zinc plating, powder coatings, and cathodic protection methods. -

Marine and Offshore Equipment

Stainless steel fittings, aluminum alloys, and anti-fouling coatings are rigorously tested to prevent pitting and galvanic corrosion in seawater-rich atmospheres. -

Electronics and Aerospace

Connectors, circuit boards, and avionics housings undergo testing to ensure functionality in saline-laden air, which can cause short circuits or structural degradation. -

Construction and Infrastructure

Architectural finishes, galvanized steel, and reinforced concrete coatings are evaluated to meet longevity standards in coastal or industrial zones.

Technical Advancements in Test Chambers

Modern salt spray chambers incorporate features to enhance precision and usability:

- Automated Controls: Programmable temperature, humidity, and spray cycles reduce operator dependency.

- Corrosion Rate Monitoring: Integrated sensors measure pH, conductivity, and deposition rates for real-time data logging.

- Multi-Cycle Testing: Alternating salt fog, drying, and humidity phases (e.g., CCT or Prohesion tests) better replicate real-world conditions.

- Material Compatibility: Chambers constructed from corrosion-resistant polymers or PP/FRP ensure long-term durability.

Interpreting Test Results

Post-test analysis includes visual inspection for blistering, rust formation, or coating delamination, quantified using standards like ASTM D1654. Advanced techniques such as electrochemical impedance spectroscopy (EIS) or scanning electron microscopy (SEM) provide microstructural insights.

Regulatory and Quality Compliance

Compliance with international standards (e.g., DIN 50021, JIS Z 2371) is mandatory for industries requiring corrosion-resistant certification. Test reports are often audited by third parties to meet OEM or military specifications (e.g., MIL-STD-810).

The salt spray corrosion test chamber remains indispensable for quality assurance in corrosion-prone industries. By simulating aggressive saline environments, manufacturers can optimize material selection and protective treatments, ultimately reducing failure rates and lifecycle costs. Continuous innovation in testing protocols ensures alignment with evolving environmental and performance demands.