The Role of Thermal Shock Chambers as the Cornerstone of Product Reliability

Author:LINPIN Update Time:2025-09-04 Source:LINPIN1. The Criticality of Environmental Stress Testing

Product reliability is a fundamental requirement across industries, from aerospace to consumer electronics. Among the various environmental stress tests, thermal shock testing stands out as one of the most rigorous methods for evaluating product durability. Thermal shock chambers, also known as temperature cycling test chambers, subject products to rapid transitions between extreme high and low temperatures, simulating real-world conditions that may cause material fatigue, component failure, or performance degradation.

The ability of a product to withstand sudden temperature changes is a strong indicator of its long-term reliability. Unlike gradual temperature variations, thermal shock induces immediate stress on materials, exposing weaknesses that might otherwise remain undetected in standard environmental tests. This makes thermal shock testing an indispensable tool in quality assurance and product validation.

2. Mechanisms of Thermal Shock Chambers

Thermal shock chambers operate by rapidly transferring test specimens between two independently controlled temperature zones—one for extreme heat and another for extreme cold. The transition time between these zones is minimized to maximize the thermal stress effect. Advanced models achieve transition times as fast as 5 to 10 seconds, ensuring that the product experiences the full impact of thermal expansion and contraction.

The testing process typically follows industry standards such as MIL-STD-810, IEC 60068, and JESD22-A104, which define test parameters including temperature extremes, dwell times, and cycle counts. By adhering to these standards, manufacturers ensure that their products meet regulatory and customer expectations for reliability in harsh environments.

3. Applications Across Industries

1)Aerospace and Defense

Aircraft components, avionics, and military hardware must endure extreme temperature fluctuations during operation. Thermal shock testing ensures that these critical systems remain functional even when exposed to rapid altitude changes or extreme weather conditions.

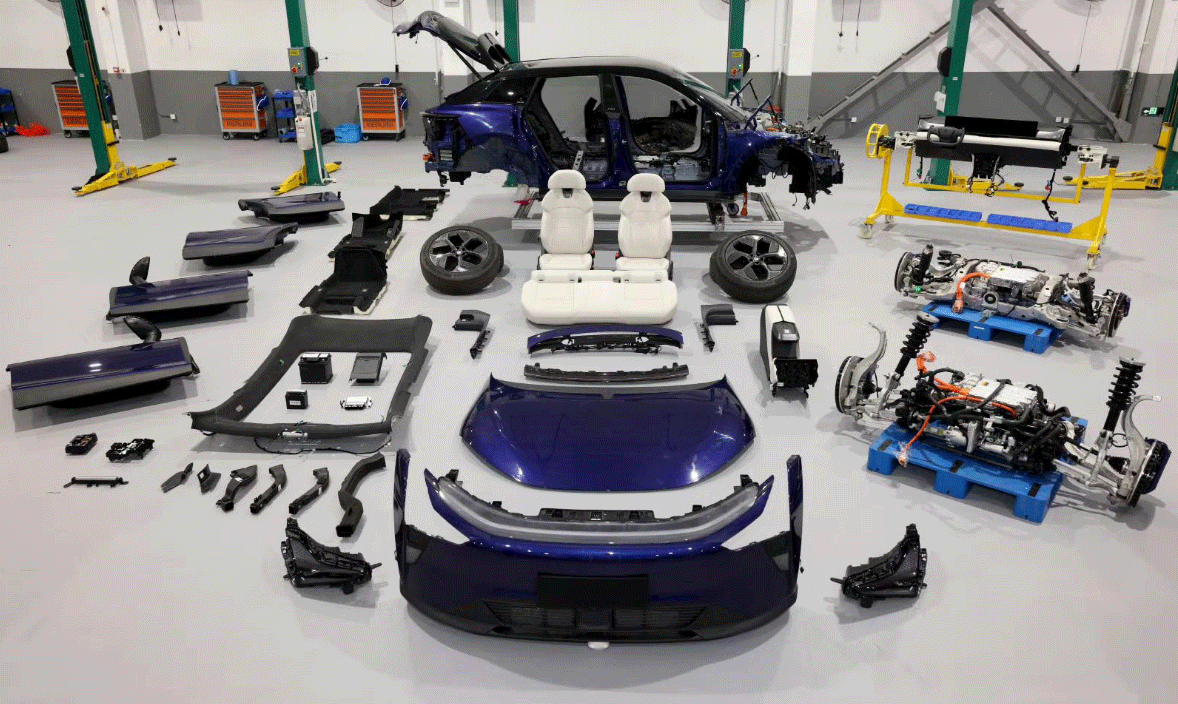

2)Automotive Electronics

Modern vehicles rely on sophisticated electronic control units (ECUs), sensors, and infotainment systems. These components must perform reliably despite exposure to engine heat, winter cold, and sudden temperature shifts. Thermal shock chambers help automotive manufacturers validate the robustness of these systems before mass production.

3)Consumer Electronics

Smartphones, laptops, and wearable devices are frequently subjected to temperature variations due to environmental exposure or internal heating. Manufacturers use thermal shock testing to identify potential failure points in solder joints, displays, and batteries, ensuring long-term performance and safety.

4) Medical Devices

Medical equipment, particularly implantable devices and diagnostic tools, must maintain functionality under varying thermal conditions. Thermal shock testing helps verify that materials and electronics within these devices will not degrade over time.

4. Advantages Over Conventional Environmental Testing

While steady-state temperature and humidity tests provide valuable data, they do not replicate the abrupt thermal transitions that many products experience in real-world applications. Thermal shock chambers offer several distinct advantages:

- Accelerated Failure Detection – By inducing rapid thermal stress, these chambers reveal latent defects much faster than prolonged exposure tests.

- Material Behavior Analysis – Engineers can observe how different materials expand, contract, and interact under extreme temperature shifts, leading to better material selection and design improvements.

- Cost Efficiency – Identifying weaknesses early in the development cycle reduces the risk of costly recalls or warranty claims post-production.

5. Technological Advancements in Thermal Shock Testing

Modern thermal shock chambers incorporate advanced features to enhance testing accuracy and efficiency:

- Automated Test Sequencing – Programmable controllers allow for precise temperature ramping, dwell times, and cycle repetitions, reducing human error.

- Multi-Zone Testing – Some chambers support multiple test zones, enabling simultaneous evaluation of different temperature profiles.

- Real-Time Monitoring – Integrated sensors and data logging provide continuous feedback on test conditions and specimen responses.

6. Conclusion

Thermal shock chambers serve as a foundational tool in reliability engineering, ensuring that products can withstand the most demanding environmental conditions. By integrating thermal shock testing into the product development lifecycle, manufacturers enhance durability, reduce failure rates, and build trust with end-users. As technology continues to evolve, the role of thermal shock testing will only grow in importance, reinforcing its status as the backbone of product reliability assurance.