Practical Tips for Salt Spray Chambers – Key Points You Didn’t Know

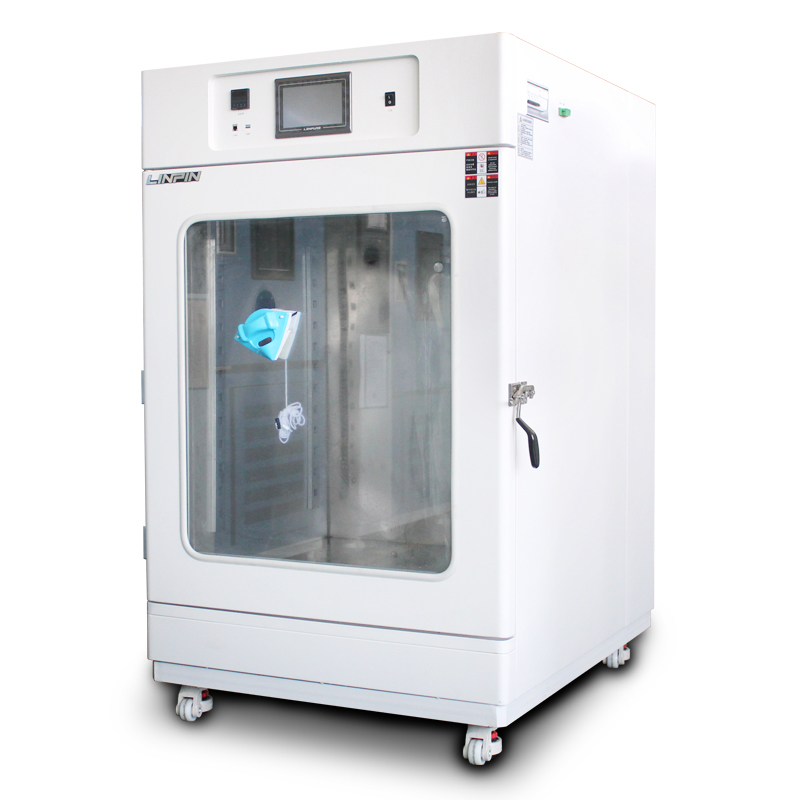

Author:LINPIN Update Time:2025-06-10 Source:LINPINA salt spray chamber is an essential device for testing the corrosion resistance of materials and coatings. Understanding some practical tips can help improve the accuracy and efficiency of testing. Below are some key points you may not be aware of:

-

Sample Pre-Treatment

Before placing samples into the salt spray chamber, they should be cleaned and pre-treated to remove surface contaminants such as oil, dust, and other impurities. Use detergents and deionized water for thorough cleaning. -

Proper Sample Placement

Ensure samples are positioned correctly inside the chamber, with sufficient spacing between them to prevent salt spray interference. Adjust the placement angle according to testing requirements. -

Salt Solution Ratio

Use the appropriate saline solution, typically a 5% sodium chloride solution, ensuring precise mixing. A precision balance and measuring cylinder can help achieve accurate proportions.

-

Temperature and Humidity Control

Maintain strict control over the chamber’s temperature and humidity. The standard test temperature is usually set at 35°C ± 2°C to ensure consistent testing conditions. -

Regular Equipment Calibration

Periodically calibrate and maintain the salt spray chamber to ensure proper functionality. Verify that all parameters meet standards to avoid inaccurate results due to equipment malfunctions. -

Observation and Documentation

Regularly monitor sample changes during testing, recording corrosion levels, time, and environmental variations for future analysis and comparison. -

Test Duration

Select an appropriate test duration based on material performance requirements. Gradually extend testing time if needed to determine the optimal test period. -

Safety Precautions

Salt spray generated during testing may pose environmental and health risks. Always operate the chamber in a well-ventilated lab and wear proper personal protective equipment (PPE). -

Standardized Test Reports

Ensure test reports are complete and accurate, including test conditions, duration, sample descriptions, and observed results. -

Comparative Testing

Conduct comparative tests to evaluate the corrosion resistance of different materials or coatings. Using standard reference materials can enhance result reliability.

By applying these tips, you can optimize the use of salt spray chambers for corrosion resistance testing, improving both reliability and accuracy.