Does Ozone Aging Test Chamber Pose a Risk of “Over-Testing”?

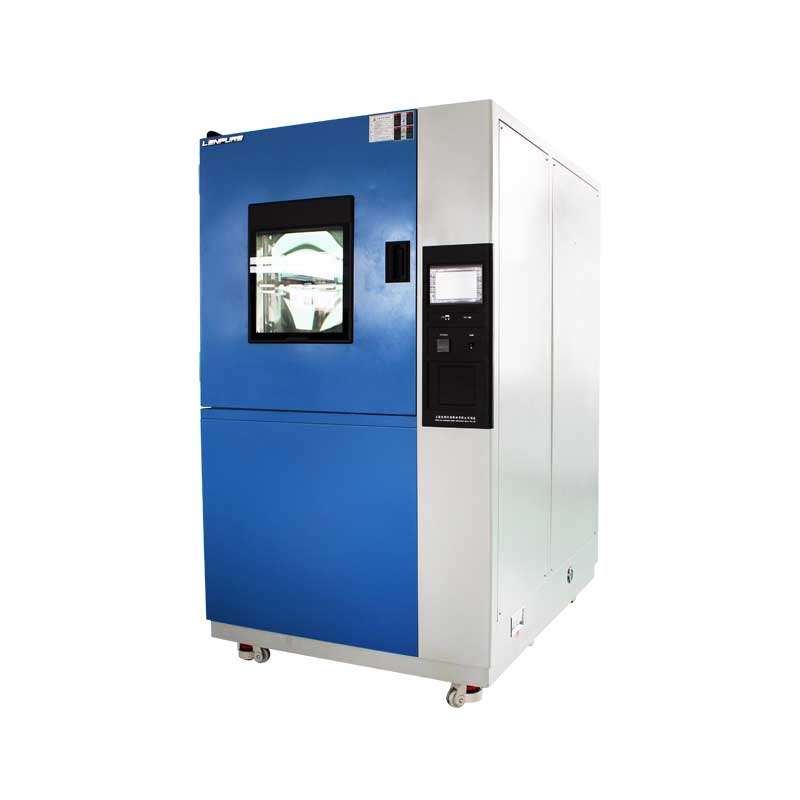

Author:LINPIN Update Time:2025-09-20 Source:LINPINThe ozone aging test chamber is an established instrument in the field of material reliability analysis. It replicates atmospheric ozone conditions at controlled concentrations to evaluate the resistance of polymers, elastomers, and coated materials against oxidative cracking and surface degradation. The use of accelerated testing is indispensable in industries such as automotive, aerospace, wire and cable, medical devices, and construction. However, a recurring concern among manufacturers and quality engineers is whether such testing may cross the threshold into “over-testing,” potentially generating results that do not correlate with real-world application environments.

The perception of “over-testing” arises when test conditions are set far above practical exposure levels. For example, ambient ozone concentration in urban or industrial regions typically ranges from 20 to 100 parts per billion (ppb). By contrast, ozone aging chambers often operate at concentrations of 50 to 200 parts per million (ppm). This represents several thousand times the environmental baseline. The accelerated exposure is intentional, as it allows evaluation within hours or days rather than over years. Yet, critics argue that results at such high concentrations may not reflect field performance.

The essential question is not whether high ozone levels are used, but whether testing protocols are standardized, repeatable, and correlated with predictive models of material lifespan. International standards such as ASTM D1149, ISO 1431, and JIS K6259 provide defined test parameters, including ozone concentration, temperature, relative humidity, and specimen strain. By adhering to these protocols, laboratories ensure that results maintain comparability and predictive value. In this context, “over-testing” is mitigated because the severity of conditions is normalized and validated by decades of industry experience.

The distinction between valid accelerated testing and destructive “over-testing” lies in the alignment of test purpose with material application. For elastomer seals in aerospace fuel systems, failure due to ozone cracking may result in catastrophic outcomes. Therefore, conservative testing margins are justified. For consumer-grade products such as footwear soles or rubber gaskets for household appliances, test specifications may be less severe. The risk of “over-testing” emerges when engineers indiscriminately apply the most rigorous test parameters to products where such exposure is neither expected nor relevant. This misalignment may lead to unnecessary rejection of materials, inflated development costs, or misinterpretation of durability.

Another factor influencing perceptions of “over-testing” is specimen preparation. Surface cleanliness, tensile strain, and sample thickness directly influence susceptibility to cracking. A poorly prepared specimen may fail prematurely, creating the illusion of exaggerated ozone sensitivity. Modern ozone aging chambers address this by offering programmable tension fixtures, precise airflow regulation, and continuous ozone monitoring sensors, ensuring that only controlled variables—not unintended artifacts—affect outcomes.

The technical sophistication of contemporary ozone chambers also counters concerns about “over-testing.” Earlier-generation equipment relied on static ozone generation with limited feedback control, which often produced fluctuations in concentration. Excessive peaks beyond the set point could accelerate degradation artificially. Today’s systems employ UV photometric or electrochemical analyzers, with closed-loop control stabilizing ozone concentration within ±1 ppm. This precision removes one of the historical sources of overexposure, enhancing both reproducibility and credibility of results.

Industries that have integrated ozone aging tests into their qualification protocols have found strong correlation with field performance when data is interpreted correctly. For example, automotive rubber hose manufacturers routinely use ozone chambers to assess the impact of both static and dynamic strain under ozone exposure. Field studies demonstrate that materials passing these laboratory tests exhibit significantly reduced incidence of surface cracking and embrittlement during vehicle operation. Far from representing “over-testing,” the chamber serves as a predictive safeguard, eliminating materials that would otherwise fail prematurely.

It is also essential to recognize that accelerated testing does not aim to replicate exact field conditions. Instead, it functions as a stress test, revealing latent vulnerabilities in molecular structure. Ozone attacks carbon–carbon double bonds, producing chain scission and surface fissures. Materials with higher saturation or protective stabilizers withstand such attacks more effectively. The chamber accelerates this process so that manufacturers can differentiate resilient formulations from weaker ones within a practical timeframe. To characterize this as “over-testing” misunderstands the purpose: the test is not a literal simulation of years of environmental exposure, but a diagnostic tool for comparative evaluation.

Concerns about unnecessary severity can be addressed by tailoring test parameters to specific industries. For aerospace and defense, 200 ppm ozone at elevated strain may be entirely appropriate. For consumer products, manufacturers may adopt lower concentrations or shorter test durations, balancing rigor with realism. The versatility of modern ozone chambers allows customization, so the risk of over-testing is not inherent to the technology but to its misapplication.

Another safeguard lies in cross-validation with complementary methods. Ozone aging results are often analyzed alongside thermal aging, UV weathering, and salt spray testing. This multi-modal approach ensures that conclusions are not based solely on one form of accelerated stress. For example, a rubber gasket that fails rapidly under ozone stress but performs well under combined heat and humidity may still be suitable for certain applications. Proper interpretation requires integration of multiple datasets, ensuring that the role of ozone degradation is accurately weighted.

Manufacturers adopting ozone chambers as part of their quality assurance frameworks also benefit from traceability. Modern systems log ozone concentration, chamber temperature, and humidity in real time, generating detailed compliance records. This documentation provides evidence for regulatory audits and supports warranty claims. Rather than risking reputational damage from premature product failures, companies using ozone testing demonstrate due diligence, strengthening both customer trust and market competitiveness.

The concept of “over-testing” must also be balanced against the cost of under-testing. A failed seal in a medical device, a cracked insulation layer in a power cable, or a degraded O-ring in a chemical pipeline can have consequences far more severe than the cost of conservative testing. The risk of rejecting a marginally suitable material due to stringent ozone testing is minimal compared with the liabilities associated with catastrophic in-service failure. From this perspective, the so-called “over-testing” is a strategic margin of safety.

Technological advances continue to refine ozone chamber applications. Intelligent control systems now allow gradual ramp-up of ozone concentration, dynamic strain cycling, and combined stress protocols simulating multi-factor aging. These improvements provide data that is both accelerated and realistic, minimizing the gap between laboratory results and field performance. As predictive analytics integrate with test results, manufacturers can forecast material lifespan with increasing accuracy, further reducing the perception of excessive testing severity.

Ultimately, the concern about ozone chamber “over-testing” arises not from the instrument itself but from misinterpretation of its role. When applied in accordance with international standards, aligned with material function, and interpreted within a broader reliability framework, the ozone aging chamber is not an instrument of over-exaggeration but of precision and foresight. Its capacity to reveal latent vulnerabilities before they manifest in real-world conditions is its greatest strength.

For industries committed to durability, safety, and compliance, the ozone aging test chamber remains an indispensable tool. The key lies not in questioning whether it imposes “too much” stress, but in ensuring that testing programs are intelligently designed, data is responsibly interpreted, and results are applied proportionately to product requirements. In this framework, what some may call “over-testing” is more accurately described as rigorous quality assurance, safeguarding both manufacturers and end-users from the far greater risks of premature material failure.