How Thermal Vacuum Chambers Expose Latent Defects in Products

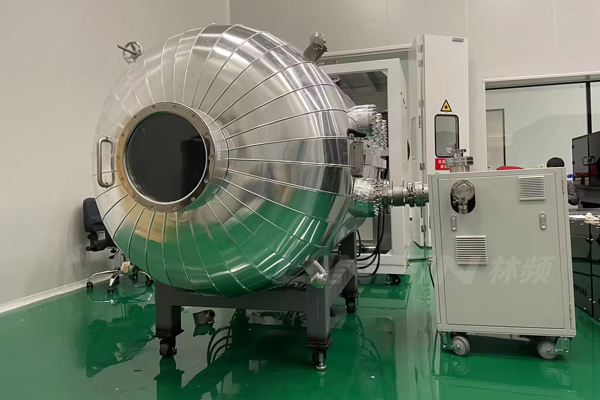

Author:LINPIN Update Time:2025-09-19 Source:LINPINThermal vacuum testing has become an indispensable method for identifying vulnerabilities in aerospace components, electronic assemblies, satellite payloads, and advanced materials. By simulating the combined effects of extreme temperature fluctuations and low-pressure environments, a thermal vacuum chamber reveals weaknesses that remain hidden under conventional laboratory conditions. The methodology provides insight into reliability, endurance, and long-term performance, ensuring that only robust products progress to mission-critical applications.

Stress Conditions Beyond Conventional Testing

Standard temperature cycling or thermal shock tests operate at ambient pressure, where convection and conduction stabilize the specimen. In contrast, a thermal vacuum chamber removes atmospheric support. This absence of convection amplifies temperature gradients across materials and forces heat transfer to occur primarily through radiation and conduction. The resulting stress state more closely resembles the operating conditions of spacecraft, satellites, and high-altitude avionics.

Products exposed to this environment face thermal loads far exceeding those produced in a standard climatic chamber. The thermal vacuum system may subject a specimen to rapid swings from sub-zero cryogenic levels to elevated temperatures exceeding 150 °C, all within a high-vacuum envelope. Such parameters generate structural strain, accelerate outgassing phenomena, and highlight inconsistencies in thermal conductivity.

Detection of Material Fatigue

Latent material fatigue is among the most critical defects revealed in thermal vacuum testing. Components manufactured with heterogeneous alloys, imperfect grain structures, or residual stresses often endure short-term qualification tests without incident. However, under vacuum and repeated temperature cycling, micro-cracks propagate rapidly. The absence of atmospheric damping magnifies vibrational sensitivity and leads to premature mechanical failure.

Thermal vacuum testing is therefore effective in disclosing defects such as:

-

Micro-fractures in solder joints

-

Delamination in composite panels

-

Surface micro-voids within high-performance polymers

-

Bond line degradation in adhesive layers

The chamber provides quantitative data regarding crack initiation thresholds, enabling engineers to reinforce weak interfaces before field deployment.

Evaluation of Outgassing and Volatile Emissions

A vacuum environment forces entrapped volatiles to escape from materials. Adhesives, lubricants, coatings, and polymer composites may contain residual solvents or unreacted monomers. When placed under high vacuum and elevated temperature, these compounds vaporize. Outgassing leads to molecular deposition on critical surfaces such as optical lenses, sensors, or solar cell arrays.

The chamber identifies materials susceptible to outgassing by monitoring weight loss, volatile condensation, and contamination rates. This evaluation ensures compliance with standards such as ASTM E595 or ECSS-Q-ST-70-02. Manufacturers are able to verify that their products maintain dimensional stability and functional clarity in space applications.

Identification of Electrical Weakness

Electronic devices exposed to thermal vacuum stress undergo performance fluctuations not visible during routine bench testing. The absence of convection alters cooling dynamics, resulting in localized hot spots within integrated circuits. Temperature extremes accelerate migration of conductive particles, causing dielectric breakdown or electromigration failures.

Testing uncovers:

-

Insufficient insulation resistance under vacuum

-

Weak solder fillets on printed circuit boards

-

Capacitor dielectric instability at cryogenic temperatures

-

Connector deformation due to mismatched coefficients of thermal expansion

By reproducing the vacuum and thermal environment, design engineers can confirm electrical stability across mission profiles and eliminate early-life failures.

Structural Integrity Under Combined Stress

Thermal cycling alone evaluates resistance to expansion and contraction. Vacuum alone examines resilience to pressure differentials. A combined thermal vacuum chamber unites these stresses simultaneously, amplifying their effects. Components bonded by adhesives may separate when subjected to thermal expansion while deprived of atmospheric support. Glass-to-metal seals, optical windows, and hermetically sealed housings demonstrate their true durability only under such dual exposure.

Leak testing integrated into the thermal vacuum process provides detection of micro-leak paths invisible under standard pressure. This ensures that pressure vessels, electronic enclosures, and sealed batteries maintain integrity throughout extended operational lifetimes.

Verification of Surface Coatings and Finishes

Protective coatings play a vital role in space hardware. Metallic platings, thermal control coatings, and radiation-resistant layers safeguard structural elements from degradation. Thermal vacuum testing identifies whether coatings maintain adhesion and stability when subjected to intense ultraviolet exposure, thermal gradients, and vacuum-induced stress.

Failure mechanisms revealed include:

-

Cracking of reflective thermal coatings

-

Blistering of anodized layers under rapid thermal swings

-

Loss of adhesion between substrate and deposited films

-

Flaking of surface treatments due to vacuum-induced outgassing

By replicating orbital conditions, the chamber validates coating performance for extended missions.

Accelerated Aging and Life Prediction

Beyond defect discovery, thermal vacuum chambers provide predictive data for long-term reliability. By subjecting a specimen to accelerated stress cycles, the chamber compresses years of service into weeks of laboratory testing. Components accumulate equivalent fatigue damage, thermal strain, and molecular changes within a shortened timeframe.

This predictive capability allows engineers to forecast mean time to failure (MTTF), establish preventive maintenance intervals, and refine material selection. The process delivers measurable assurance that