Analysis of the Differences Between Forced Air Drying Ovens and Industrial Ovens

Author:LINPIN Update Time:2025-05-29 Source:LINPINIn both laboratory and industrial production processes, drying equipment plays a crucial role. Forced air drying ovens and industrial ovens are both common types of drying equipment. While they share some similarities in purpose, there are distinct differences in their structure, functionality, and application scenarios. Below, we provide an in-depth analysis of these differences to help you select the most suitable drying equipment.

I. Equipment Structure and Working Principle

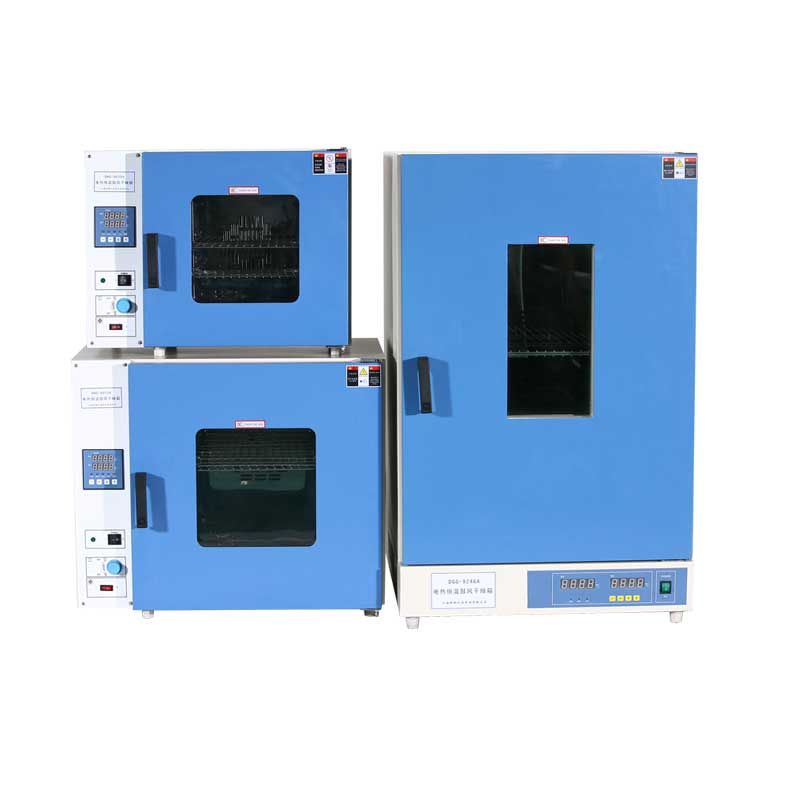

Forced air drying ovens typically employ natural or forced convection, using a fan to generate uniform airflow and accelerate the evaporation of moisture from samples. Their internal structure is relatively compact, making them suitable for small-scale, precision drying tasks.

Industrial ovens, on the other hand, are designed to be more robust and are generally used for large-scale production. They offer higher temperature control precision and can accommodate larger items. Additionally, industrial ovens often utilize hot air circulation technology to ensure even heating at high temperatures, thereby improving drying efficiency.

II. Temperature Control and Performance

The temperature range of forced air drying ovens is relatively limited, typically between 50°C and 200°C, making them suitable for temperature-sensitive materials. Industrial ovens, however, can reach much higher temperatures—sometimes exceeding 300°C—making them ideal for a variety of industrial applications.

Furthermore, the data monitoring system of forced air drying ovens is relatively simple, whereas industrial ovens are usually equipped with more advanced temperature control systems to ensure stable drying performance even during prolonged operation.

III. Scope of Application

Forced air drying ovens are generally used in scientific research, education, and similar fields, making them well-suited for laboratories and small-batch product drying where high precision is required.

Industrial ovens, in contrast, are widely applied in manufacturing, food processing, chemical industries, and other sectors, particularly in scenarios requiring prolonged high-temperature treatment, where they are indispensable.

In summary, while both forced air drying ovens and industrial ovens serve as drying equipment, they each have their own emphasis in terms of structure, performance, and application areas. The key to selecting the right drying equipment lies in clearly understanding your specific needs and operational environment.