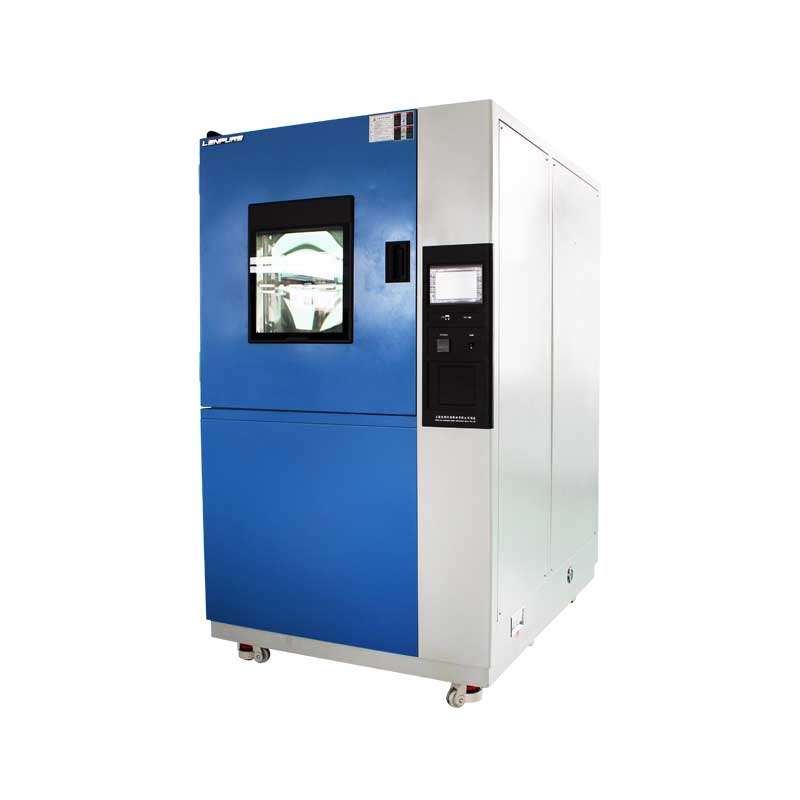

Xenon Lamp Aging Test Chamber

Product Usage :The Xenon Lamp Aging Test Chamber(Water-Cooled Xenon Lamp Weathering Test Chamber) utilizes xenon arc lamps that can simulate the full solar spectrum to reproduce destructive light waves present in various environments. It can provide corresponding environmental simulation and accelerated photodegradation testing for scientific research, product development, and quality control.

Apply to:

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Model | Studio Size (D*W*H)mm | Dimension(D*W*H)mm | |

| LRHS-767S-SN | 950×950×750 | 1560×1500×1730 | |

| temperature range | RT+10℃~80℃ | ||||||

| Humidity range | 65%~98%RH | ||||||

| Blackboard temperature | 63℃~100℃ | ||||||

| Temperature uniformity | ≤2.0℃(in darkness) | ||||||

| Temperature fluctuation | ±0.5℃(in darkness) | ||||||

| Humidity Deviation | +2、-3% RH | ||||||

| Nozzle Aperture | Ф0.8mm | ||||||

| rainfall pressure | 0.12~0.15Mpa | ||||||

| timing of rainfall | 1~999M,Adjustable for continuous rainfall | ||||||

| Spraying cycle | 18min/102min或12min/48min(Spraying time/stopping time) | ||||||

| photoperiod | 1~999h、m、scontinuously adjustable | ||||||

| sample holder | 360°rotation, rotation rate 1r~5r/min | ||||||

| template | 75×150mm(standard samples, customizable) | ||||||

| longitudinal | 290~800nm | ||||||

| radiation intensity | ≤1200W/㎡ | ||||||

| Xenon lamp power | 6.0kW | ||||||

| Heating power | 4.0kW | ||||||

| Humidifying power | 3.0kW | ||||||

| Outer case material | High quality A3 steel plate electrostatic spraying | ||||||

| Inner box material | Imported high-grade stainless steel SUS304 | ||||||

| Temperature and humidity controller | “Taiwan Weilun” touch screen + ‘Germany Siemens’ PLC module | ||||||

| Temperature and humidity sensors | PT100 platinum resistance temperature measurement body | ||||||

| standard configuration | 2 lamps, 1 set of sample holders | ||||||

| security protection | Compressor overpressure overload, water shortage protection, fan motor overheating, the overall equipment over temperature The whole machine under phase/reverse phase, equipment timing, leakage protection, automatic shutdown after fault alarm and other protection. |

||||||

| Supply Voltage | AC380V±10% 50Hz | ||||||

| Power | 15.0kW | ||||||

| operating environment | 5℃~+30℃ ≤85%RH | ||||||

| Note: 1、the test data are used in the ambient temperature of 25 ℃ and well ventilated conditions measured 2、Can be customized according to the specific requirements of the user non-standard Xenon Lamp Aging Test Chamber etc 3、This technical information, subject to change without notice |

|||||||

Feature

The main features of the Xenon Lamp Aging Test Chamber:

1. High performance and quiet operation (20~ 70 dBa)

2. Touch-screen controller, user-friendly

3. Import Q-Lab air-cooled Full spectrum xenon lamp, more economical, more efficient and easier to maintain. Lamp life of 1800 hours.

4. The flat sample mounting tray can accommodate different shapes and sizes of samples, including 3D parts. There are a variety of sample stents to choose from

5. The irradiance control system continuously monitors and controls the output of the light, which ensures accurate exposure and repeatable test results.

7. Allows the user to simultaneously control and monitor relative humidity, blackboard temperature and air temperature in the box.

8. All circuits fused or circuit breaker protected, overload protection.

9. All wiring numbered or color coded 10. Tri-color Indicator and EMO (Emergency-off Switch) available.

1. High performance and quiet operation (20~ 70 dBa)

2. Touch-screen controller, user-friendly

3. Import Q-Lab air-cooled Full spectrum xenon lamp, more economical, more efficient and easier to maintain. Lamp life of 1800 hours.

4. The flat sample mounting tray can accommodate different shapes and sizes of samples, including 3D parts. There are a variety of sample stents to choose from

5. The irradiance control system continuously monitors and controls the output of the light, which ensures accurate exposure and repeatable test results.

7. Allows the user to simultaneously control and monitor relative humidity, blackboard temperature and air temperature in the box.

8. All circuits fused or circuit breaker protected, overload protection.

9. All wiring numbered or color coded 10. Tri-color Indicator and EMO (Emergency-off Switch) available.

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…