What Types of Rainfall Can a Rain Test Chamber Simulate?

Product Usage :A rain test chamber does more than simply spray water—it faithfully recreates real-world rainfall conditions in accordance with stringent national and international standards (such as IEC, IP protection ratings, GB/T, etc.).

Apply to:

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

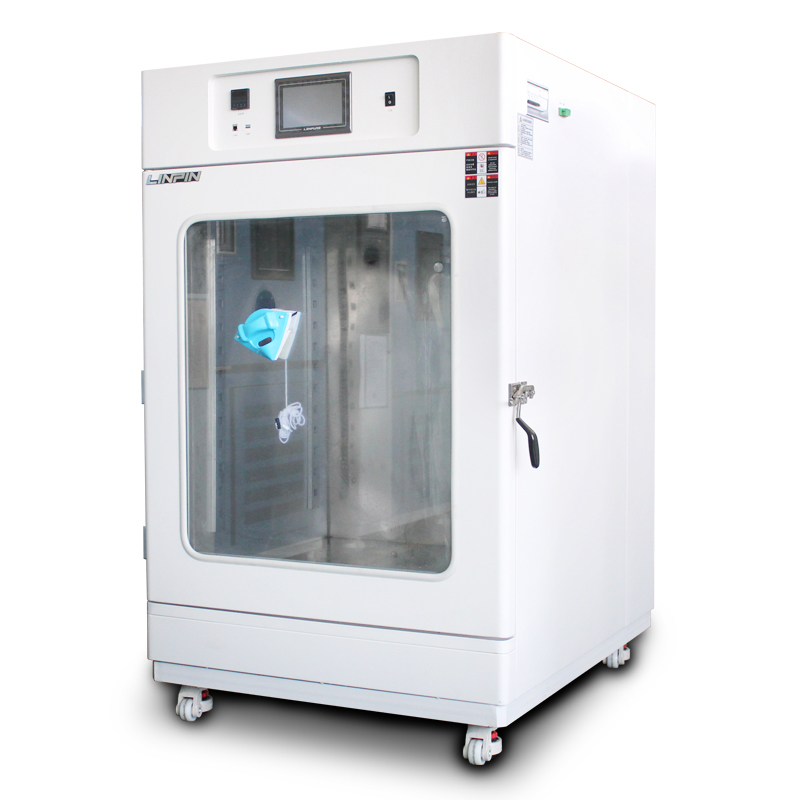

In today’s demanding landscape of product quality and reliability, ensuring that products perform consistently under various harsh weather conditions has become a critical challenge for manufacturers. Among these challenges, water ingress due to rainfall is a common cause of product failure. As a specialized environmental reliability testing equipment, the rain test chamber plays a vital role by accurately replicating a wide range of natural rainfall conditions, providing scientific and authoritative validation for product waterproof performance.

I. Comprehensive Simulation to Tackle Complex Rainfall Challenges

A rain test chamber does more than simply spray water—it faithfully recreates real-world rainfall conditions in accordance with stringent national and international standards (such as IEC, IP protection ratings, GB/T, etc.). It is capable of simulating the following key environments:

Steady Moderate to Heavy Rainfall: Simulates prolonged, uniform-intensity rain to evaluate the ability of product enclosures to resist continuous water penetration. This is crucial for products like outdoor cabinets, communication base stations, and automotive lighting that are consistently exposed to rain.

Multi-Angle and Multi-Directional Spray: Natural wind-driven rain comes from all directions. Advanced rain test chambers feature adjustable spray systems that can direct water vertically, horizontally, or at any specified angle. This mimics real-world wind-blown rain scenarios, thoroughly assessing waterproof performance on all sides of the product.

High-Intensity Rain and Water Jet Impact: For products requiring higher protection levels (e.g., IPX5, IPX6), the test chamber can simulate high-flow, high-pressure water jets or powerful splashing conditions. This is mainly used to evaluate the water resistance and impact durability of components such as vehicle parts and outdoor surveillance equipment under extreme weather.

Extended Simulation for IPX7/X8 Immersion Tests: Some integrated rain test chambers also support temporary or continuous immersion tests, verifying whether the product enclosure can prevent harmful water ingress under specified depth and duration conditions.

II. Core Value: Enhancing Product Competitiveness from the Design Stage

Introducing rain test chamber validation early in the product development process offers benefits that go far beyond merely identifying issues:

Improved Design Reliability: During R&D, simulation testing helps identify weaknesses in sealing design and material selection early, effectively preventing market complaints or recalls due to waterproofing defects.

Shortened Certification Cycles: In-house testing capability significantly reduces the time required for third-party IP rating certifications, accelerating time to market.

Enhanced Brand Reputation: Products proven reliable under rigorous rainfall conditions build strong user trust and reinforce brand credibility through demonstrated durability and performance.

The rain test chamber serves as a bridge connecting product design with real-world environmental conditions. By scientifically simulating diverse rainfall scenarios, it offers manufacturers a crucial tool to anticipate risks, verify quality, and strengthen competitiveness. Investing in professional rain testing is a solid step toward ensuring long-term product success.

Feature

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…