What is the Role of the Saturation Tower in a Salt Spray Corrosion Test Chamber? Can It Be Omitted?

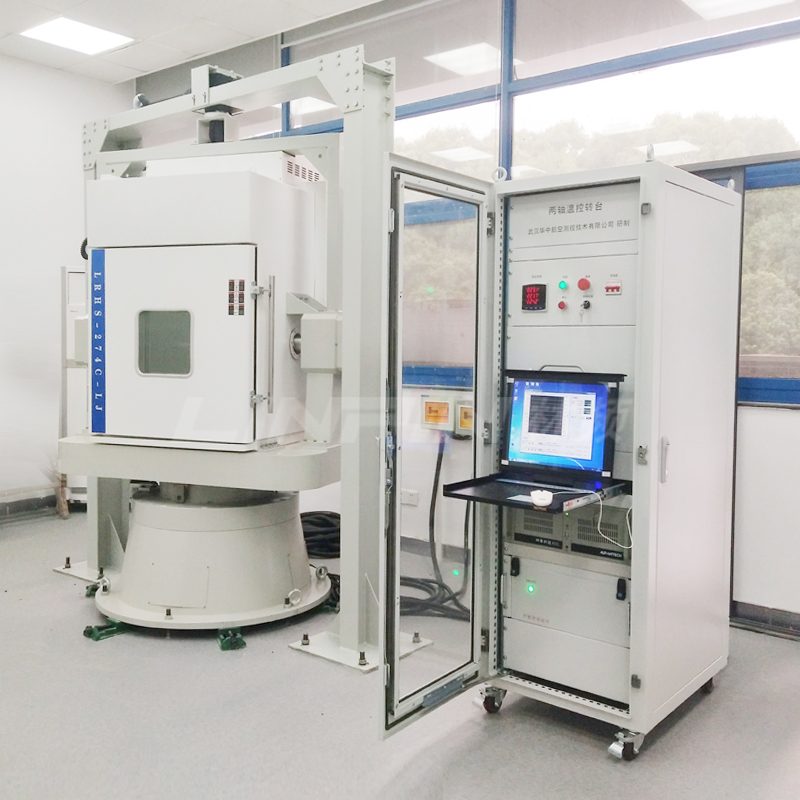

Author:LINPIN Update Time:2025-08-26 Source:LINPINIn industries such as manufacturing, automotive, electronics, and aerospace, the corrosion resistance of products is critical. Salt spray corrosion test chambers, as essential tools for simulating harsh environments, are widely used to evaluate the anti-corrosion performance of various materials. Within these chambers, the saturation tower plays a vital role—often considered the "heart" of the entire system.

However, many users do not fully understand the function of the saturation tower, and some even question: "Is the saturation tower really necessary? Can it be skipped?" Today, we will delve into the purpose, working principles, and irreplaceable role of the saturation tower in salt spray testing.

1. What is a Saturation Tower?

The saturation tower (also called a saturation air barrel or saturator) is a critical component of a salt spray corrosion test chamber. Its primary function is to humidify and heat compressed air, ensuring it meets the required temperature and humidity conditions for testing, thereby guaranteeing uniform and stable salt spray distribution.

Structure of the Saturation Tower

- Heating System: Typically uses electric heating to warm the air to the set temperature (usually close to the test temperature, e.g., 50°C).

- Water Level Control: Maintains optimal water levels via a float valve or electronic sensor to ensure proper air humidification.

- Air Filtration System: Removes impurities and oil from compressed air to prevent nozzle clogging or test interference.

How It Works

Compressed air enters the saturation tower, where it is heated and humidified until reaching near 100% relative humidity. This saturated air then mixes with the salt solution and is atomized through the nozzle, creating a consistent salt spray environment.

2. Key Functions of the Saturation Tower

Ensures Uniform Salt Spray Distribution

The core requirement of salt spray testing is consistent and stable spray distribution. Unsaturated air can cause fluctuations in humidity and temperature, leading to uneven spray patterns and unreliable test results.

Prevents Nozzle Clogging

Untreated air may contain contaminants or be too dry, which can cause salt buildup and nozzle blockage over time. The saturation tower’s humidification and filtration functions mitigate this risk.

Maintains Stable Test Temperature

Salt spray tests typically require a constant temperature (e.g., 35°C or 50°C). The saturation tower preheats the air, ensuring the sprayed mist matches the chamber’s internal temperature and preventing condensation or test deviations.

Enhances Test Accuracy

International standards (e.g., ASTM B117, ISO 9227) mandate the use of a saturation tower to ensure standardized testing conditions. Omitting it may invalidate test results, affecting product certifications.

3. Can the Saturation Tower Be Omitted?

Technically, a salt spray chamber can operate without a saturation tower—but at a significant cost:

- Uneven spray distribution, leading to unreliable data.

- Nozzle damage from dry air, increasing maintenance costs.

- Non-compliance with industry standards, risking product certification failures.

- Reduced equipment lifespan due to improper operation.

Thus, the saturation tower is not just a core component but a non-negotiable element for test accuracy and compliance.

4. How to Maintain the Saturation Tower?

To ensure long-term performance:

✔ Use distilled water (avoid tap water to prevent scaling).

✔ Clean the tower interior every 1-2 months to remove salt deposits.

✔ Inspect the heating system for consistent temperature control.

✔ Check water level controls to prevent over/under-humidification.

5. What to Consider When Buying a Salt Spray Chamber?

If you’re purchasing a salt spray test chamber, prioritize the saturation tower’s quality:

✅ Material: Stainless steel (e.g., 316L) for superior corrosion resistance.

✅ Heating Method: PID temperature control ensures precision.

✅ Water Level System: Auto-refill functions reduce manual intervention.

✅ Brand Reputation: Choose reputable manufacturers compliant with ASTM/ISO standards.

Final Thoughts

Though less conspicuous than nozzles or control systems, the saturation tower is the unsung hero of salt spray testing. It silently ensures humidification, heating, and filtration, guaranteeing accurate and repeatable test results.

Operating without a saturation tower is like sailing without a compass—directionless and unreliable. Whether for equipment longevity, test precision, or regulatory compliance, the saturation tower is indispensable.