What are the functional features of cyclic salt spray corrosion test chambers?

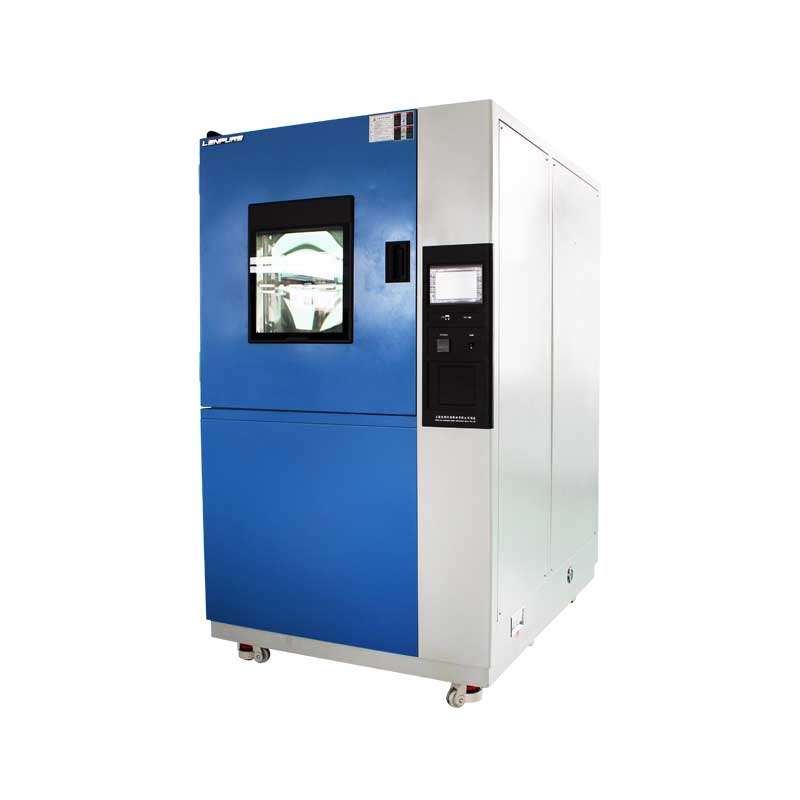

Author:LINPIN Update Time:2025-07-04 Source:LINPINIn modern industrial production, the corrosion resistance of materials directly impacts product quality and lifespan. To effectively evaluate material performance in salt spray environments, cyclic salt spray corrosion test chambers have been developed. Below is a detailed introduction to the functional features of these chambers to help you gain a comprehensive understanding of this equipment.

Simulation of Real Environments

Cyclic salt spray corrosion test chambers precisely control temperature, humidity, and salt spray concentration to simulate marine, industrial, or other salt-laden environments. This high degree of realism ensures more reliable test results, aiding in the research and improvement of anti-corrosion materials and technologies.

Alternating Test Function

Unlike traditional salt spray test chambers, cyclic salt spray corrosion test chambers can perform alternating corrosion tests. This involves periodic transitions between salt spray and dry environments, simulating material performance in variable real-world conditions—particularly suitable for materials used in multi-climate regions.

Automated Control System

Modern cyclic salt spray corrosion test chambers are equipped with advanced automated control systems that monitor and adjust test parameters in real time. This intelligent operation not only enhances test accuracy but also significantly reduces the workload for operators, making the testing process more efficient.

Multiple Testing Capabilities

In addition to salt spray corrosion tests, cyclic salt spray corrosion test chambers support various other material corrosion resistance evaluations, such as mold tests and high-temperature tests. This versatility makes the equipment highly valuable in both research and industrial applications.

Durable Design

To meet the demands of long-term, high-intensity use, cyclic salt spray corrosion test chambers are constructed with corrosion-resistant and wear-resistant materials. The interior chamber is typically made of stainless steel or treated with anti-corrosion coatings, extending the equipment's service life.

Compliance with International Standards

Cyclic salt spray corrosion test chambers comply with international standards such as ISO 9227, ensuring the authority and comparability of test results. This is particularly important for companies requiring certification, as it enhances product competitiveness in the market.

Data Recording and Analysis

The built-in data logging function records real-time test data and generates detailed reports. This not only facilitates analysis of test results but also provides valuable insights for subsequent material improvements.

The low-cost investment and high-return performance evaluation of cyclic salt spray corrosion test chambers make them indispensable tools in material testing. Whether for research institutions or manufacturing enterprises, using high-quality cyclic salt spray corrosion test chambers can effectively enhance product competitiveness and market recognition.