What are the common faults of UV aging test chambers?

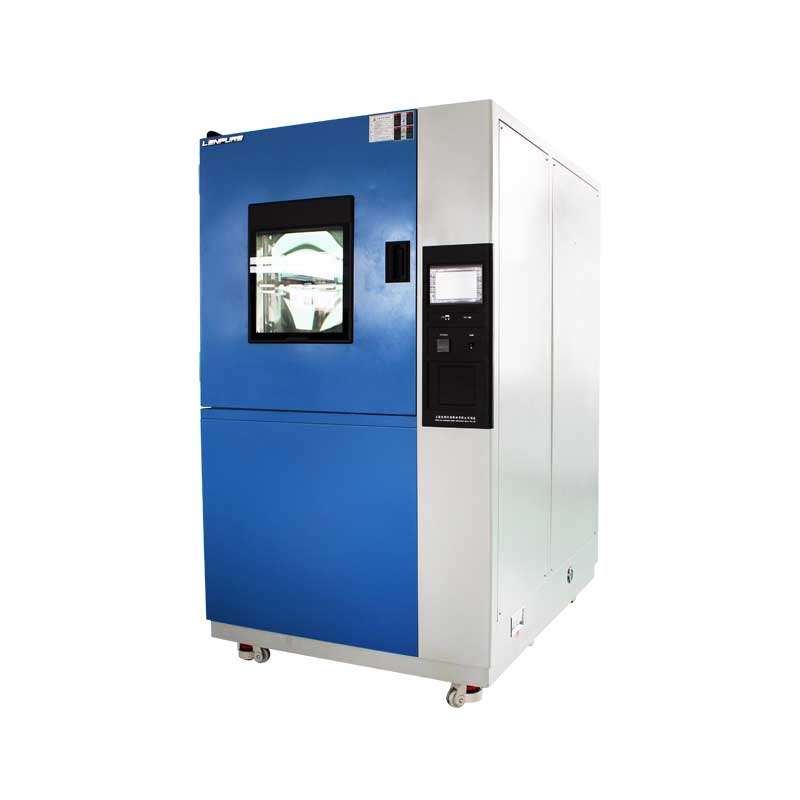

Author:LINPIN Update Time:2025-04-11 Source:LINPINThe UV aging test chamber mainly uses fluorescent lamps as the light source to simulate the effects of UV radiation in the natural environment on materials and test samples. The results of the tests are used to directly analyze their performance. The scope of this test chamber is very broad, and it is generally used in fields such as aviation, aerospace, electronics, electrical engineering, and scientific research. Of course, during the testing process, various faults may occur. So, what should we do in such cases?

Linpin Instruments has 18 years of experience in the environmental testing equipment industry. Next, the editor of Linpin will recount these experiences based on the explanations from professionals.

Fault One: The UV lamps do not light up when the UV aging test chamber is in use. The main reason is that the fluorescent UV aging test chamber uses electronic ballasts. The wiring can be a bit tricky, and the plug-in type may lead to loose connections or poor contact of the lamp corner wires. The ends of the UV lamps turn black.

Fault Two: As we all know, the filaments of household light bulbs are made of tungsten, which has a very high melting point of 3410°C. Normally, there should be no blackening. However, when physical sublimation occurs, the problem is revealed. To avoid this, do not frequently turn the lamps on and off. Once the lamp is lit, do not turn it off within at least three hours.

Fault Three: The UV water trough rusts through. The UV water trough is used to hold water for heating to simulate a natural condensation environment (which should be done at night). If the device is not used according to the specified instructions and tap water is added instead of deionized water for the test, the trough will be corroded over time and eventually rust through. Therefore, it is essential to use deionized water during use.

Fault Four: The water trough heating tube needs to be replaced frequently. Not using the specified deionized water also leads to the heating tube being immersed in tap water for a long time. Through chemical reactions, it is known that rust will form on the surface of the heating tube, increasing the frequency of heating tube replacements.

Fault Five: The instruments fail frequently. The instruments of the UV aging test chamber are installed at the top of the device. After several days or even weeks of operation, the temperature of the device can rise significantly. Without air conditioning in some laboratories, the heat accumulates, and the instruments are subjected to prolonged high temperatures, which can lead to failures.

The UV aging test chamber plays a significant role in important fields by analyzing the anti-aging performance of products through test results. However, to obtain more accurate test results, it is crucial to ensure that the device operates without any unexpected issues. Now that these common faults have been identified, solving them should not be too difficult.