The Critical Role of Salt Spray Test Chambers in Electroplating Quality Inspection

Author:LINPIN Update Time:2025-08-23 Source:LINPINA drop of saltwater may seem insignificant, yet it can instantly reveal the hidden vulnerabilities of a metal surface. A salt spray test chamber, on the other hand, acts as a silent judge, impartially and precisely evaluating the corrosion resistance of electroplated coatings. As manufacturing demands for durability and reliability grow increasingly stringent, salt spray test chambers have evolved from laboratory equipment to an "essential tool" for electroplating quality control. They not only validate the effectiveness of plating processes but also provide robust data to help clients mitigate risks, extend product lifespans, and enhance brand credibility.

Why Must Electroplated Coatings Undergo Salt Spray Testing?

Electroplated coatings primarily serve to enhance corrosion resistance and aesthetics. However, environmental factors—such as marine climates, industrial atmospheres, or saline-alkali soils—pose long-term threats due to chloride exposure.

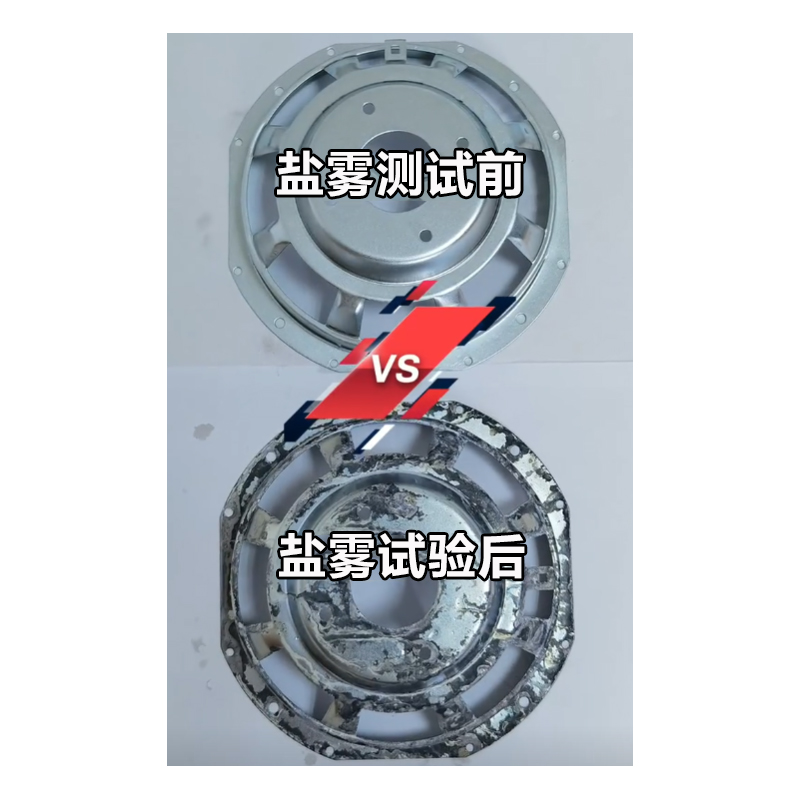

Visual inspections or basic adhesion tests cannot predict real-world performance under prolonged exposure. Salt spray testing accelerates corrosion simulation in a controlled environment, quickly exposing potential defects (e.g., pinholes, cracks, uneven coating, or poor substrate preparation).

For exported products or critical components (e.g., automotive parts, marine hardware, electronic enclosures, or metal fittings), standardized salt spray test reports serve as proof of compliance and a mark of trustworthiness.

Key Functions and Advantages of Salt Spray Test Chambers

-

Accelerated Aging for Rapid Assessment

Salt spray testing simulates years of environmental exposure in just hours or weeks, drastically shortening validation cycles and enabling faster, data-driven production decisions. -

Precision Simulation of Diverse Corrosive Environments

Modern chambers support Neutral Salt Spray (NSS), Acetic Acid Salt Spray (AASS), and Cyclic Corrosion (CASS) modes, catering to varying industry standards and client requirements—from routine to extreme conditions. -

Early Defect Detection to Reduce Rework Costs

Systematic, repeatable testing identifies coating flaws and process issues early, preventing costly mass recalls or post-shipment failures—safeguarding both budgets and brand reputation. -

Traceable, Standardized Reporting

Test data complies with ISO, ASTM, DIN, and other international standards, offering credible quality certification while supporting process optimization, supplier audits, and quality management. -

Driving R&D and Process Innovation

For new materials, coating systems, or additive formulations, salt spray testing serves as a critical benchmarking tool, helping engineers compare corrosion resistance and accelerate development.

Integrating Salt Spray Testing into Electroplating Quality Control

- Standardized Testing Protocols: Define test types (NSS/AASS/CASS), durations, and pass/fail criteria based on product applications and client specifications.

- Process Correlation: Link test results to pretreatment, bath chemistry, and plating parameters (current density, temperature, time) for closed-loop improvements.

- Equipment Calibration & Maintenance: Ensure stability of temperature, spray volume, and droplet size to guarantee data accuracy and repeatability.

- Team Training: Enhance defect recognition and root-cause analysis (e.g., substrate prep, thickness variation, contaminants) for consistent quality judgments.

Case Study Highlights

- An automotive parts manufacturer reduced customer complaints by 70% within three months after salt spray testing exposed inconsistent pretreatment by a supplier. Adjusting cleaning agents and activation time resolved the issue.

- A hardware supplier used cyclic corrosion tests to optimize a new plating formula, boosting export compliance rates from 85% to 98% and securing high-value contracts.

In industrial manufacturing, quality is competitiveness, and reliability is credibility. A salt spray test chamber is more than an inspection device—it’s a diagnostic scalpel that exposes hidden weaknesses in electroplated coatings, guides process refinements, and ultimately delivers market-ready confidence.