One-Stop Guide: Salt Spray Test Methods (NSS, AASS, CASS) – Everything You Need to Know

Author:LINPIN Update Time:2025-08-23 Source:LINPINIn today’s hyper-competitive market, corrosion-related product failures can silently sabotage brand reputation, shorten equipment lifespan, and drain after-sales profits. To ensure customer confidence and product reliability, businesses must treat salt spray resistance as a non-negotiable passport to market entry. This guide breaks down the three core salt spray test methods—NSS (Neutral Salt Spray), AASS (Acetic Acid Salt Spray), and CASS (Copper-Accelerated Acetic Acid Salt Spray)—covering principles, procedures, evaluation criteria, and selection strategies to eliminate corrosion risks before they escalate.

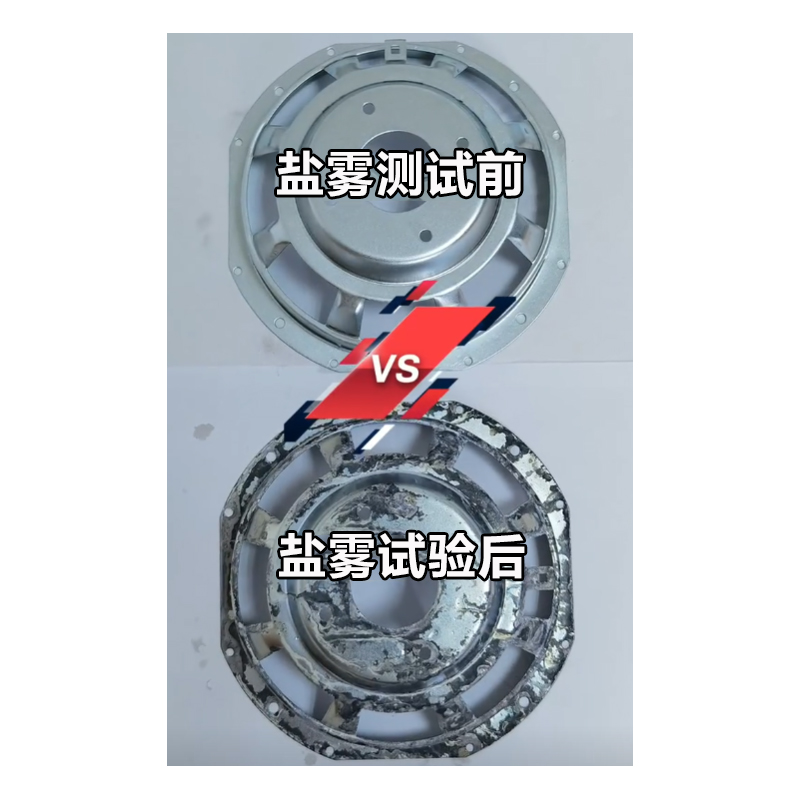

Part 1: Why Salt Spray Testing Matters

Salt spray testing simulates corrosive attacks from marine or industrial environments (dominated by NaCl and acidic contaminants) on materials and coatings. It serves as a standardized, accelerated benchmark to:

- Identify design flaws, material weaknesses, or process gaps before mass production.

- Optimize coatings, plating, and material formulations to reduce recalls and warranty costs.

- Meet industry-specific requirements (e.g., automotive, electronics, marine hardware, coatings, and electroplated parts).

Part 2: The Big Three Salt Spray Test Methods

1. NSS (Neutral Salt Spray)

- Principle: Sprays a 5% NaCl solution (pH 6.5–7.2) at 35°C to mimic general salt-laden environments.

- Best for: Evaluating bare metals, coatings, or platings in neutral conditions; widely used for material screening and process control.

- Pros: Mild conditions, excellent reproducibility, and broad applicability (e.g., ISO 9227, ASTM B117).

- Limitations: Less aggressive; may not reflect acidic/industrial corrosion scenarios.

2. AASS (Acetic Acid Salt Spray)

- Principle: Adds acetic acid to 5% NaCl, lowering pH to 3.1–3.3 for harsher acidic corrosion.

- Best for: Testing painted surfaces, thin platings, or materials vulnerable to acidic degradation (e.g., ASTM G85 Annex A).

- Pros: Faster defect detection (e.g., coating delamination, porosity).

- Limitations: Overly aggressive for some applications; not universally representative.

3. CASS (Copper-Accelerated Acetic Acid Salt Spray)

- Principle: Enhances AASS by adding 50 ppm copper ions (from CuCl₂) to accelerate corrosion, especially for copper-containing materials.

- Best for: Nickel/chromium plating, brass components, or parts exposed to copper contamination (common in electronics/automotive).

- Pros: Rapidly exposes failures like pitting, discoloration, or coating breaches.

- Limitations: Extremely aggressive; best suited for failure analysis or QC screening, not standalone certification.

Part 3: Key Standards & Parameters

- Standards:

- NSS: ISO 9227, ASTM B117

- AASS: ISO 9227 (modified), ASTM G85 Annex A

- CASS: ISO 9227 variants, ASTM G85 Annex A/B

- Critical Conditions:

- Solution: 5% NaCl (±0.1%)

- pH: NSS (6.5–7.2), AASS/CASS (3.1–3.3)

- Temperature: Typically 35°C (varies by standard)

- Spray cycles: Continuous or intermittent (per protocol)

- Sample placement: Angle, spacing, and duration must follow specifications.

Part 4: How to Choose the Right Test

- By Industry:

- General metals/coatings: Start with NSS.

- Acid-sensitive coatings/paints: Opt for AASS.

- Electroplated/copper-alloy parts: Use CASS.

- By Objective:

- R&D validation: Combine multiple tests for robustness.

- Quality control: Align with client/industry standards (e.g., automotive OEMs often mandate CASS).

- Failure analysis: Prioritize CASS/AASS for accelerated defect revelation.

- Cost & Time:

- NSS is the most cost-effective with moderate duration.

- AASS/CASS require stricter post-test handling and maintenance.

Final Takeaway

Salt spray testing isn’t just about "dunking samples in salty water"—it’s a strategic tool to preempt corrosion risks, refine designs, and secure certifications. Understanding NSS, AASS, and CASS empowers you to:

✔ Prevent costly field failures by catching weaknesses early.

✔ Streamline compliance with industry-specific requirements.

✔ Gain a competitive edge in tenders and audits.

Invest in the right test, and corrosion won’t stand a chance.