The Challenger in High-Temperature and High-Vacuum Environments: The Boundless Potential of Thermal Vacuum Chambers!

Author:LINPIN Update Time:2025-06-12 Source:LINPINWith the continuous advancement of technology and industrial development, the demand for testing material and equipment performance under high-temperature and high-vacuum conditions has grown significantly. In this challenging environment, thermal vacuum chambers have become an irreplaceable tool, offering limitless possibilities for researchers across various industries.

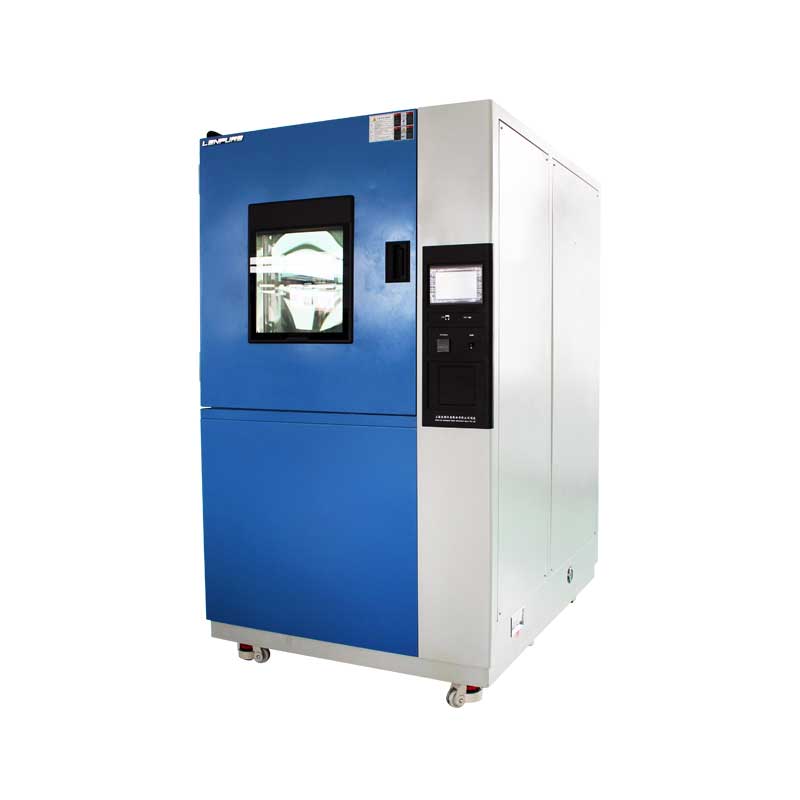

A thermal vacuum chamber is a device capable of simulating high-temperature and high-vacuum conditions. By precisely controlling temperature and pressure, it enables the testing of material and equipment endurance under extreme conditions. It is not only used for material research and performance evaluation but also plays a crucial role in product development and quality control in industries such as aerospace, automotive, and semiconductors.

Challenges in High-Temperature and High-Vacuum Environments

Materials and equipment face numerous challenges in such extreme conditions. First is the impact of high temperatures—thermal expansion and increased stress can lead to material cracking and deformation. Meanwhile, the ultra-low pressure in a high-vacuum environment accelerates gas diffusion and volatilization within materials, potentially causing irreversible performance degradation.

How Thermal Vacuum Chambers Overcome These Challenges

Thermal vacuum chambers accurately simulate these extreme conditions, providing reliable data for performance evaluation. Equipped with advanced heating and cooling systems, they enable rapid and stable temperature adjustments to meet diverse testing requirements. Additionally, their high-efficiency vacuum systems quickly evacuate gases, achieving the desired vacuum levels.

Endless Applications Across Industries

The versatility of thermal vacuum chambers extends beyond environmental simulation to a wide range of applications:

- Aerospace: Simulating space conditions to test the reliability and durability of spacecraft components in a vacuum.

- Automotive: Evaluating the performance and lifespan of engine parts and batteries under extreme heat and vacuum.

- Semiconductors: Assessing the stability and reliability of semiconductor devices in harsh conditions.

The Future of Thermal Vacuum Chambers

As technology evolves, thermal vacuum chambers continue to innovate, enhancing their capabilities. Future advancements may include:

- Smart automation: AI-driven control and real-time data acquisition for improved efficiency and accuracy.

- Integrated testing systems: Seamless connectivity with other testing equipment for comprehensive performance analysis.

Conclusion

Whether overcoming the challenges of extreme environments or pushing the boundaries of material and product performance, thermal vacuum chambers remain an indispensable tool. Their limitless potential will continue to drive technological progress, empowering researchers to achieve groundbreaking innovations. The future of thermal vacuum chambers promises even greater possibilities—let’s embrace the exciting advancements ahead!