Industries Requiring Rapid Temperature Change Test Chambers for Reliability Testing

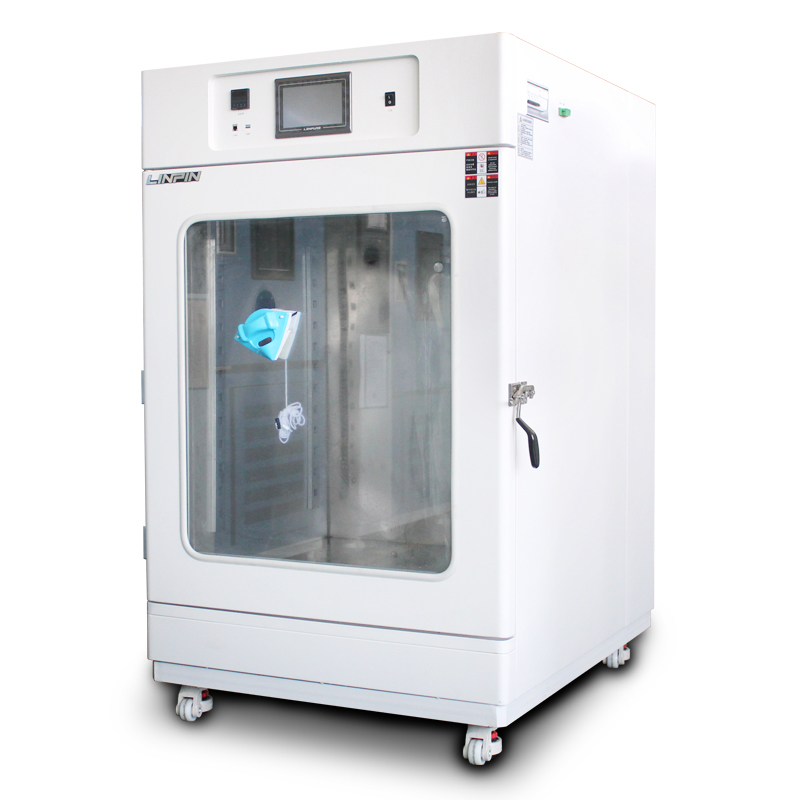

Author:LINPIN Update Time:2025-09-06 Source:LINPINReliability testing is a critical phase in product development, ensuring that components and systems perform as intended under various environmental conditions. Among the most essential tools for such evaluations are rapid temperature change test chambers, which simulate extreme thermal fluctuations to identify potential failures. Several industries rely heavily on these chambers to validate product durability, safety, and compliance with international standards.

1. Aerospace and Defense

The aerospace and defense sectors demand rigorous reliability testing due to the extreme conditions encountered during flight, space missions, and military operations. Components such as avionics, propulsion systems, and satellite equipment must withstand rapid temperature shifts from high-altitude cold to engine-generated heat. Rapid temperature change test chambers replicate these conditions, exposing materials to thermal shocks that verify structural integrity and operational stability.

Military-grade electronics, radar systems, and communication devices also undergo accelerated thermal cycling to ensure functionality in harsh environments. Without such testing, undetected material fatigue or electronic malfunctions could lead to catastrophic failures in critical applications.

2. Automotive Industry

Modern vehicles incorporate advanced electronics, battery systems, and composite materials that must endure fluctuating temperatures. Electric vehicle (EV) batteries, for example, require validation under rapid thermal transitions to assess performance, lifespan, and safety risks like thermal runaway.

Automotive manufacturers use rapid temperature change test chambers to evaluate components such as engine control units (ECUs), sensors, and infotainment systems. These tests simulate conditions ranging from desert heat to arctic cold, ensuring reliability across diverse climates. Additionally, materials used in exterior components (e.g., seals, adhesives, and plastics) are tested for resistance to thermal expansion and contraction.

3. Electronics and Semiconductors

The electronics industry relies on rapid thermal cycling to assess the durability of semiconductors, printed circuit boards (PCBs), and microprocessors. Temperature fluctuations can cause solder joint fractures, delamination, or electrical failures, particularly in high-performance computing and consumer electronics.

Semiconductor manufacturers subject wafers and chips to extreme thermal stress to identify defects early in production. Devices destined for industrial, medical, or automotive applications must pass stringent thermal shock tests to meet industry standards such as JEDEC and IPC.

4. Medical Devices and Pharmaceuticals

Medical equipment, including implantable devices, diagnostic tools, and laboratory instruments, must operate reliably under varying temperatures. Rapid temperature change testing ensures that materials remain stable during sterilization processes, storage, or transportation. For instance, insulin pumps and pacemakers are tested to prevent malfunctions caused by thermal expansion or condensation.

In pharmaceuticals, stability testing of vaccines, biologics, and drugs often involves controlled thermal cycling to validate shelf life and efficacy. Regulatory agencies like the FDA and EMA mandate such tests to ensure product safety under real-world conditions.

5. Renewable Energy Systems

Solar panels, wind turbines, and energy storage systems are exposed to daily and seasonal temperature variations. Photovoltaic modules, for example, undergo thermal cycling tests to evaluate resistance to cracking, delamination, and efficiency loss. Battery storage systems, particularly lithium-ion units, are tested for thermal management performance to prevent degradation or hazardous failures.

6. Telecommunications

Network infrastructure, including 5G base stations, fiber-optic cables, and satellite communications, must endure temperature extremes without signal loss or hardware damage. Rapid temperature change testing validates the resilience of these systems in environments ranging from scorching deserts to freezing tundras.

Rapid temperature change test chambers are indispensable across industries where product reliability is non-negotiable. By subjecting materials and components to controlled thermal shocks, manufacturers can preemptively address weaknesses, comply with regulations, and deliver high-performance products capable of withstanding real-world demands. Investing in advanced thermal testing solutions ensures long-term durability, safety, and customer satisfaction in competitive global markets.