High and Low Temperature Shock Test Chamber: Providing Reliable Assurance for Product Quality Testing!

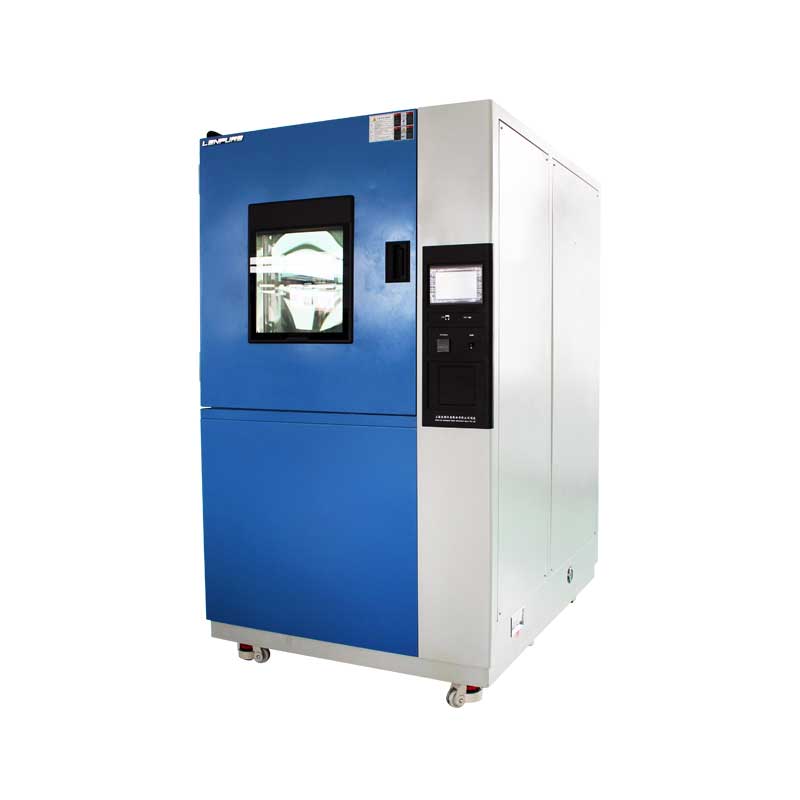

Author:LINPIN Update Time:2025-05-07 Source:LINPINThe High and Low Temperature Shock Test Chamber is a specialized device for product quality testing, designed to simulate harsh environmental conditions. It subjects products to extreme temperature variations to ensure their reliability and stability under severe thermal stress.

Typically, theHigh and Low Temperature Shock Test Chamber consists of two independent chambers—one for high-temperature exposure and the other for low-temperature exposure. Equipped with advanced heating and cooling systems, the chamber enables rapid temperature transitions while maintaining precise temperature control and stability.

During testing, products are placed inside the chamber and exposed to alternating high and low temperatures, which can be set according to specific requirements. Over a defined period, the products undergo multiple thermal cycles, simulating real-world temperature fluctuations they may encounter.

The High and Low Temperature Shock Test Chamber evaluates product performance and reliability under extreme temperature conditions, including heat resistance, cold resistance, and physical durability. This testing helps manufacturers identify and address potential design or manufacturing flaws, thereby enhancing product quality and dependability.

In essence, the High and Low Temperature Shock Test Chamber is a crucial tool for product quality assurance, providing manufacturers with reliable validation to ensure their products perform optimally under extreme thermal conditions.