Five Common Test Variations in Salt Spray Corrosion Test Chambers

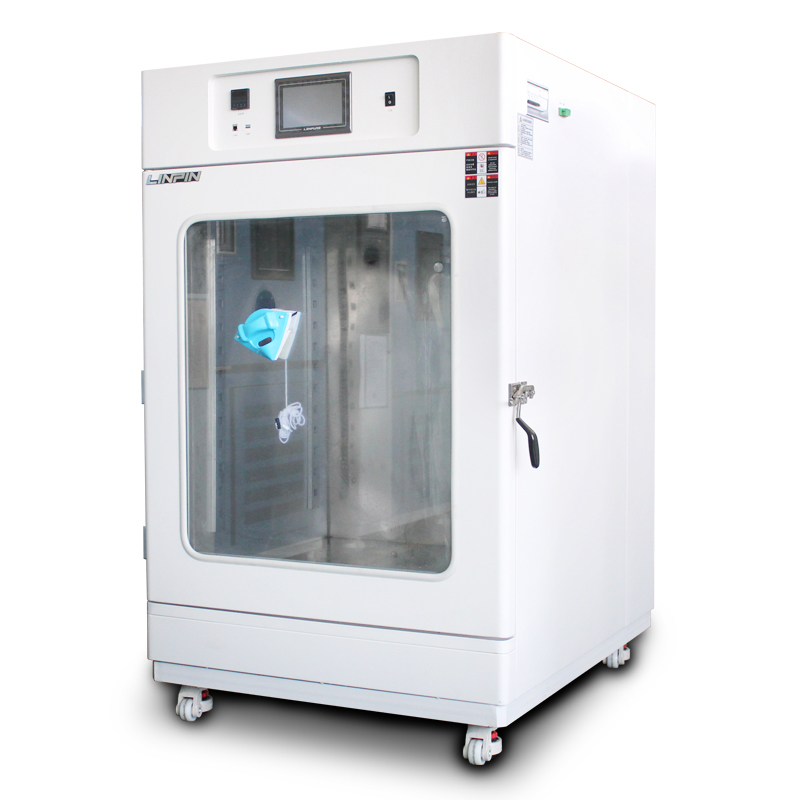

Author:LINPIN Update Time:2025-05-15 Source:LINPINSalt spray corrosion test chambers are primarily used to evaluate the corrosion resistance of metal or electroplated material surfaces by simulating a salt spray environment. These devices allow flexible adjustment of saline solution composition, making them suitable for testing the corrosion resistance of various alloys. Additionally, they can conduct corrosive gas tests, demonstrating their wide range of applications.

Causes of Test Variations

When using a salt spray corrosion test chamber, test results may vary due to multiple factors. Below are some common causes of these variations:

-

Settling Volume Issues: The standard settling volume is 1–2 ml/80 cm²/h. If two devices both fall within this range but have different specific values, the test results will naturally differ. This can be verified by comparing the total saline solution consumption during the test.

-

Settling Volume Collection Issues: Even if saline consumption is normal, the actual settling volume may be too low. This could be due to saline leakage, nozzle damage, tilted collection funnels, or clogged tubing. Such issues can distort the settling volume measurement, leading users to mistakenly believe the spray volume is insufficient.

-

Temperature Setting Differences: Variations in the temperature settings of the salt spray corrosion test chamber will naturally lead to differing test results. Ensuring accurate temperature settings is critical for reliable outcomes.

-

Saline Concentration Issues: The standard salt spray test concentration is 5% (a mass ratio of 5 parts salt to 95 parts water). If the saline concentration is too high, it will accelerate sample corrosion. Therefore, precise saline preparation is essential.

-

Saline pH Issues: The standard pH range for saline solution should be between 6.5 and 7.2. If the salt purity is insufficient or the water quality is poor, the prepared saline may fall outside this range, affecting test results.

Solutions

After identifying these common issues, the following measures can be taken to minimize test variations:

- Regularly inspect the equipment to ensure all components function properly.

- Strictly adhere to testing standards to avoid human error.

- Periodically calibrate the equipment to confirm accurate temperature and concentration settings.

- Use high-quality salt and water to ensure proper saline preparation.

By implementing these measures, test variations in salt spray corrosion test chambers can be significantly reduced, leading to more accurate and reliable test results.