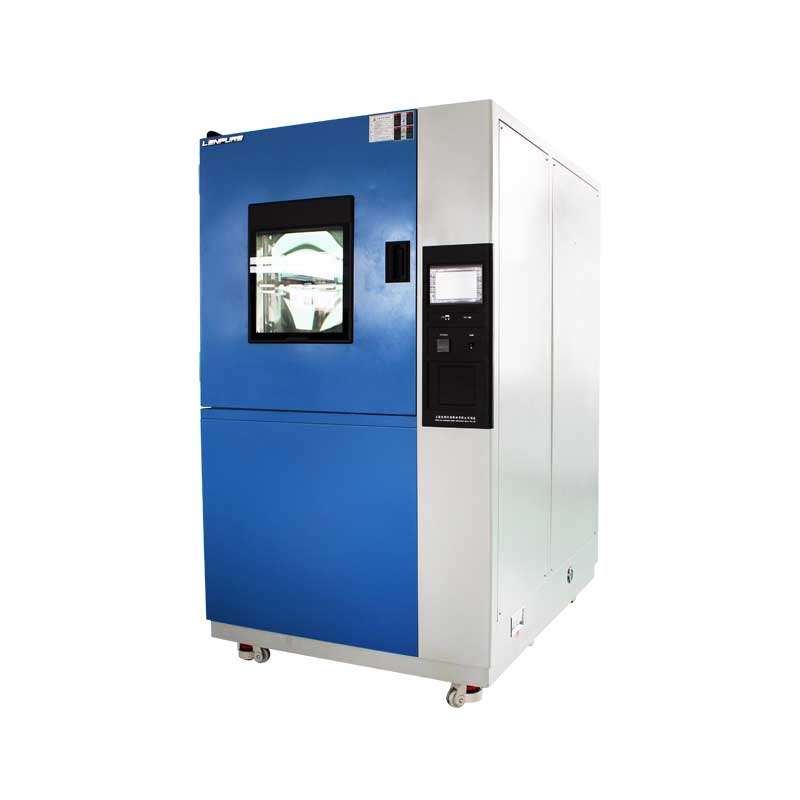

Exploring the Basics of High and Low Temperature Shock Test Chamber in Modern Industrial Production

Author:LINPIN Update Time:2025-06-17 Source:LINPINIn modern industrial production, High and Low Temperature Shock Test Chamber are commonly used testing equipment designed to simulate product performance under extreme temperature conditions. Below, we explore some fundamental knowledge about High and Low Temperature Shock Test Chamber to help you better understand this essential equipment.

1. The Role of High and Low Temperature Shock Test Chamber

High and Low Temperature Shock Test Chamber are primarily used to evaluate the performance of materials and products under rapid temperature variations. By exposing samples to different temperature environments, they simulate extreme temperature changes that products may encounter in real-world applications. This helps assess their heat resistance, cold resistance, and physical and chemical properties under thermal stress.

2. Working Principle

High and Low Temperature Shock Test Chamber use internal cooling and heating systems to rapidly decrease or increase the chamber's temperature within a short period. Samples undergo cyclic testing in the chamber, simulating thermal expansion and contraction effects under varying temperature conditions. This allows manufacturers to examine product reliability and stability in extreme thermal environments.

3. Applications

High and Low Temperature Shock Test Chamber are widely used in industries such as electronics, automotive, aerospace, and optoelectronics.

- Electronics Industry: Testing electronic components, circuit boards, smartphones, laptops, etc., under high and low temperatures.

- Automotive Industry: Evaluating the reliability of automotive parts in extreme temperature conditions.

- Aerospace Industry: Assessing the performance of aviation equipment in high-altitude freezing environments.

4. Key Parameters

Important specifications of High and Low Temperature Shock Test Chamber include:

- Temperature range

- Heating and cooling rates

- Temperature uniformity

Selecting appropriate parameters ensures accurate and reliable test results.

5. Precautions

When using a High and Low Temperature Shock Test Chamber, it is essential to:

- Maintain cleanliness inside the chamber.

- Perform regular maintenance and calibration to ensure accuracy.

- Follow safety protocols to prevent accidents caused by improper operation.

High and Low Temperature Shock Test Chamber are crucial for evaluating product performance under extreme temperature conditions, helping manufacturers enhance product quality and reliability. Understanding the fundamentals of these chambers enables better utilization, providing strong support for product development and production.