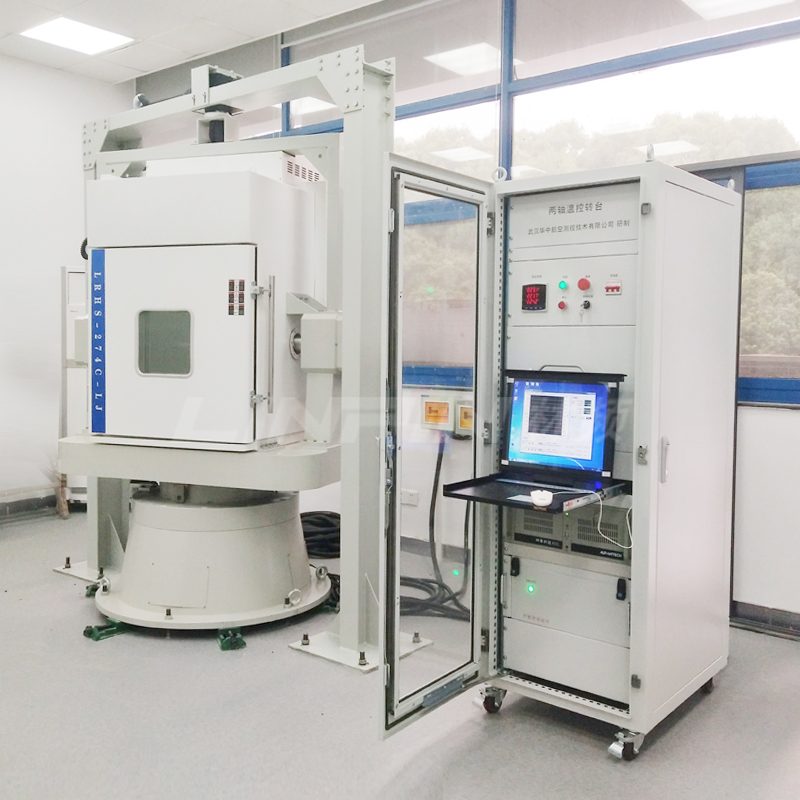

Cryogenic Test Chamber

Product Usage :Cryogenic Test Chamber(Deep cold test chamber) is mainly used in aviation, aerospace, information, electronics and other fields, to determine the instrumentation, electrical products, materials, components, equipment in the high temperature, low temperature single or simultaneous role of the environmental adaptability and reliability of the test, and or at the same time on the specimen energised for the measurement of electrical performance parameters.

Apply to:Ultra-low temperature test, Cryogenic test chamber, Deep Cold Test Chamber

Customizable :Specific product specifications and parameters can be customized according to the customer's actual situation or customization. You can contact us at any time to obtain quotations and solutions.

Parameter Details

| Device model | Studio size (D*W*H)mm | Overall dimensions (D*W*H)mm | |

| LRHS-101-LD | 450×450×500 | 1100×900×1350 | |

| LRHS-225-LD | 500×600×750 | 1150×1100×1600 | |

| LRHS-504-LD | 700×800×900 | 1350×1300×1750 | |

| LRHS-800-LD | 800×1000×1000 | 1450×1500×1850 | |

| LRHS-1000-LD | 1000×1000×1000 | 1450×1500×1850 | |

| Performance | temperature range | -196℃~room temperature | |||||

| temperature uniformity | ≤2℃ (no load) | ||||||

| temperature fluctuation | ±1℃(no load) | ||||||

| Heating rate | ≥3℃/minute | ||||||

| cooling rate | ≥3℃/minute | ||||||

| Time setting range | 1~60000 meters | ||||||

| Material | Outer box material | High quality A3 steel plate electrostatic spraying | |||||

| Inner box material | Imported high-grade stainless steel SUS304 | ||||||

| Insulation material | Rigid polyurethane foam + fiberglass | ||||||

| Basic Specification | Temperature Controller | brand temperature meter | |||||

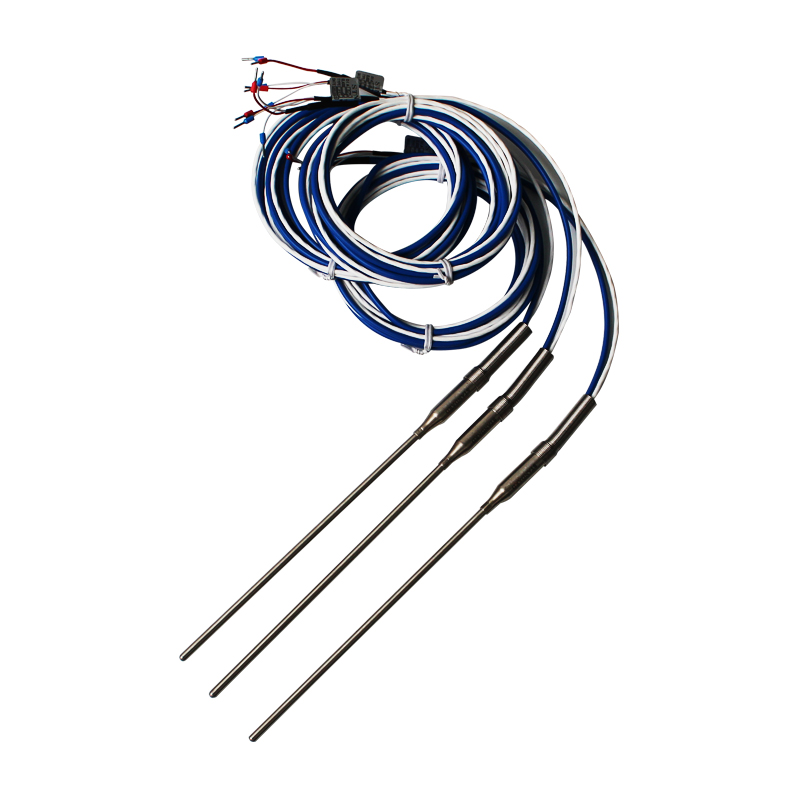

| Temperature Sensor | PT100 platinum resistance thermometer | ||||||

| Refrigeration method | Liquid nitrogen refrigeration | ||||||

| Standard configuration | The sample rack has 2 layers and is equipped with a condensation water tray and is discharged out of the box. | ||||||

| safety protection | Over-temperature, overall equipment timing, leakage protection, overload and short-circuit protection | ||||||

| voltage | AC220V±10% 50HZ AC380V±10% 50HZ | ||||||

| Power rate | 2.5kW/3.0kW/4.5kW/6.5kW/6.5kW | ||||||

| Usage environment | 5℃~+28℃ ≤85% relative humidity | ||||||

| 3. This technical information is subject to change without prior notice. | |||||||

Feature

1. The inner and outer wall surfaces are made of high-grade stainless steel SUS304, wear-resistant, low-temperature resistant performance.

2. fast cooling speed, can quickly reach the process temperature.

3. Temperature can be controlled, can be designed through the touch screen process curve.

4. Wide temperature range The temperature range is from -196℃ to room temperature, which can adapt to the extreme low temperature testing needs.

5. Flexible time setting: time setting range from 1 minute to 60,000 minutes, to meet the needs of long time testing.

6. Liquid nitrogen refrigeration, can quickly reach the low temperature state

Test standard

Submit your requirements

Application

Scope of application-

New Energy

Test chambers have extensive applications in the n… -

Rubber products

Before rubber products leave the factory, it is es… -

Electronic and electrical products

The purpose of environmental testing for electrica… -

Automotive Industry

The automotive industry must conduct numerous envi… -

Aerospace and Defense Industry

As aerospace technology advances and the defense i…