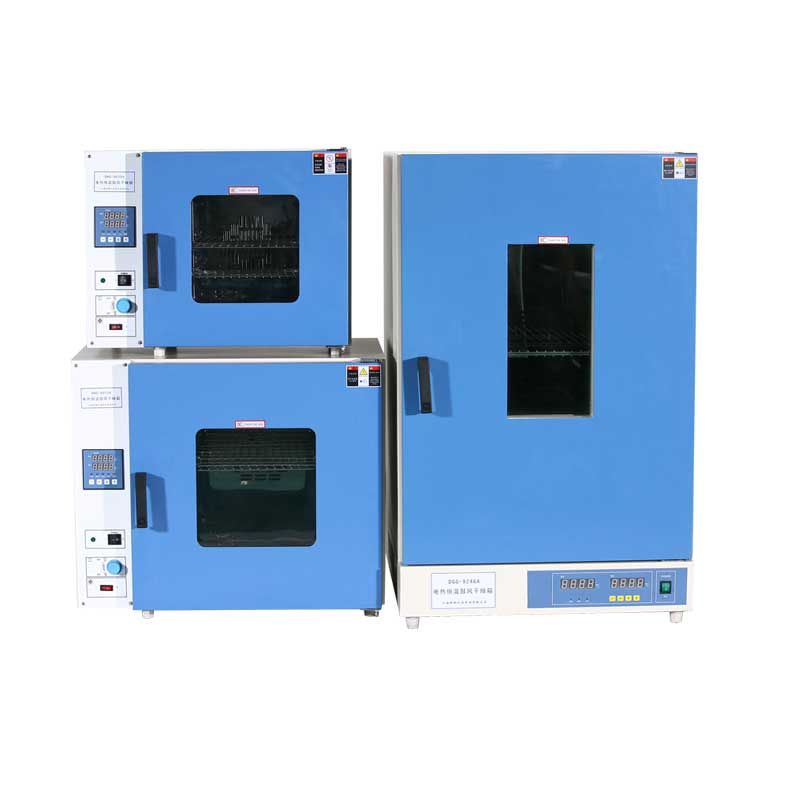

Differences Between High Low Temperature Chamber and Electric Hot Air Drying Ovens

Author:LINPIN Update Time:2025-04-23 Source:LINPINA High Low Temperature Chamber is used to evaluate and confirm the adaptability of electrical, electronic equipment, or materials under temperature cycling conditions, simulating high-temperature aging environments on product surfaces during storage and use.

-

Different Purposes:

Both are test chambers that maintain a working space temperature higher than room temperature up to a specific level. However, high and low temperature test chambers are typically used for high-temperature aging or drying of mechanical and metal samples, where the samples should not have excessive moisture content, and temperature control precision is relatively high. In contrast, electric hot air drying ovens are mostly used for drying samples with higher moisture content. These ovens are equipped with adjustable humidity exhaust pipes and generally do not require strict temperature control precision.

-

Different Structural Features:

High and low temperature test chambers have an independent air circulation duct design, where heated air circulates within a specific duct system, featuring air outlets and inlets to ensure temperature uniformity inside the chamber. Electric hot air drying ovens, however, rely on fans to directly blow hot air into the chamber, resulting in lower temperature uniformity. High and low temperature test chambers are also equipped with test lead-in ports for external power or instruments.

-

Different Controllers:

High and low temperature test chambers use imported temperature controllers with a wide experimental temperature range. They employ PT100 platinum resistance as sensors, offering high sensitivity in temperature control and strong temperature uniformity. They also feature leakage protection, over-temperature alarms, and over-temperature protection functions. Electric hot air drying ovens generally lack these features.