Automotive Parts Salt Spray Test Chamber Requirements

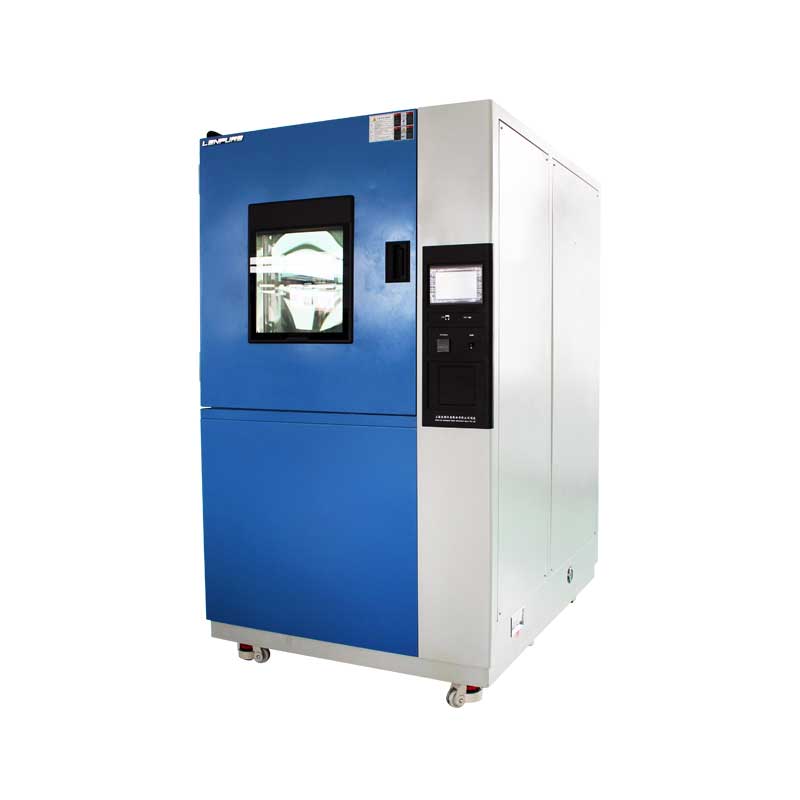

Author:LINPIN Update Time:2025-08-05 Source:LINPINIn today's highly competitive automotive industry, improving the durability and reliability of automotive parts has become a top priority for manufacturers. The salt spray test chamber, as a critical testing device, serves as a key tool in achieving this goal. By subjecting automotive parts to rigorous salt spray testing, manufacturers can effectively predict potential corrosion issues during real-world use, thereby enhancing product quality and market competitiveness.

Significance of Salt Spray Testing

Salt spray testing simulates the corrosive conditions automotive parts may encounter in marine or humid environments. This test allows manufacturers to quickly evaluate the corrosion resistance of materials in a short period. It not only improves product reliability but also reduces the high maintenance costs associated with quality issues in later stages.

Testing Requirements

When conducting salt spray tests, automotive parts must meet the following basic requirements:

-

Test Environment: The operating temperature and humidity of the salt spray test should comply with industry standards, typically set at 35°C, while the salt spray concentration must remain within the specified daily range.

-

Sample Preparation: Before testing, parts must be cleaned and dried to ensure the surface is free of oil, dust, and other contaminants, guaranteeing accurate test results.

-

Test Duration: Depending on the material and intended use of the part, the salt spray test duration may range from 48 hours to several hundred hours. The exact duration should be determined based on the expected usage environment.

-

Evaluation Criteria: Post-test assessments should include visual inspection, corrosion depth measurement, and other indicators to ensure the part's durability and commercial viability.

-

Report Analysis: After each test, a detailed report should be generated, including test conditions, result analysis, and improvement recommendations, to guide future product design and enhancements.

In the automotive industry, safety and durability are the foundation of market success. The widespread use of salt spray test chambers not only provides manufacturers with a scientific and systematic approach but also delivers more reliable and safer automotive parts to consumers. We urge all automotive manufacturers to prioritize salt spray testing to enhance product quality and secure market trust.