Working Principle of UV Weathering Test Chamber

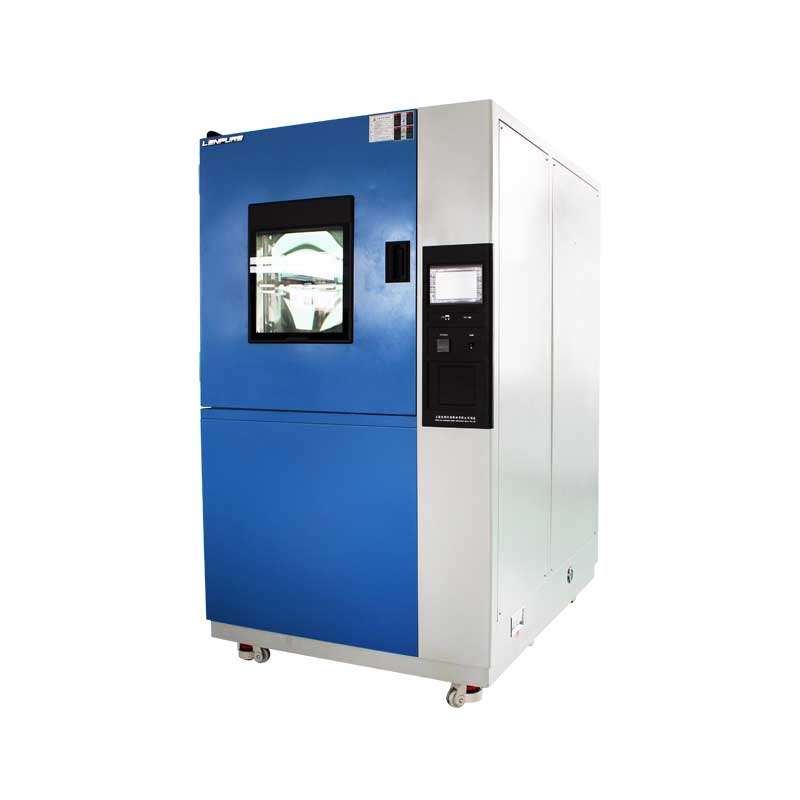

Author:LINPIN Update Time:2025-04-30 Source:LINPINThe UV Weathering Test Chamber is a laboratory device designed to simulate the material aging process caused by ultraviolet (UV) radiation in natural environments. Below is a detailed introduction to the UV Weathering Test Chamber:

I. Basic Principle

The UV Weathering Test Chamber accelerates material aging by simulating UV radiation conditions found in nature. Its core function involves using high-intensity UV light sources (typically UVA-340 lamps, which closely match the UV spectrum of sunlight) combined with precise control of temperature, humidity, and other environmental parameters. The chamber subjects samples to continuous or cyclic UV exposure, simulating years or even decades of outdoor aging effects in a short period.

II. Main Functions

- Simulation of Solar Radiation: The chamber replicates outdoor sunlight exposure, including UV rays, rain, high temperatures, and humidity, to test the weather resistance of materials under prolonged exposure.

- Climate Simulation: It can mimic various climatic conditions (e.g., tropical, subtropical, and polar climates) to evaluate material durability in different environments.

- Coating and Coating System Testing: The chamber is used to assess the weather resistance of coatings, paints, plastics, metals, and other materials.

- Material Performance Evaluation: It tests the weather resistance of materials such as plastics, rubber, wood, metals, and electronic components to determine their long-term reliability.

- Quality Control: The chamber ensures that new or existing materials meet durability and reliability standards during production.

III. Technical Parameters

- Model: LRHS-NZY

- Design Types:

- Standard tower type (for standard-sized samples)

- Chamber type (for finished product testing)

- Sample Dimensions: 365 × 75 (mm)

- Working Chamber Size: 450 × 1170 × 500 mm

- Overall Dimensions: 680 × 1420 × 1510 mm

- UV Lamps:

- UV-A (315–400 nm) or UV-B (280–315 nm)

- Brands: ATLAS or Q-Lab

- Lamp Spacing: 70 mm

- Irradiance Intensity: Adjustable from 0.4 W/m² to 1 W/m² (with radiometer)

- Light Exposure Temperature Range: RT +10°C to 70°C

- Condensation Temperature Range: 40°C to 60°C

- Temperature Tolerance: ≤ ±2°C

- Temperature Fluctuation: ±0.5°C (unloaded)

- Temperature Resolution: 0.1°C

- Black Panel Thermometer: Range 30–80°C, tolerance ±1°C

- Humidity Range: ≥95% RH

- Temperature Control Method: PID auto-tuning

- Water Tray Requirement: Water depth ≤ 25 mm

- Power Supply: AC220V ±10%, 50Hz

IV. Features

- High UV Simulation Accuracy: The chamber accurately replicates natural UV radiation, including UV-A, UV-B, and UV-C wavelengths, with adjustable settings for different material requirements.

- Precise Control: It features advanced temperature and humidity control systems for accurate environmental regulation, ensuring reliable and repeatable test results.

- Large Capacity & Multi-Functionality: The chamber offers ample testing space for multiple samples, improving efficiency. Optional accessories (e.g., sample racks, turntables) enhance versatility.

- User-Friendly Operation: Equipped with a touchscreen control panel, it allows easy parameter setting, real-time monitoring (temperature, humidity, UV intensity), and alarm functions.

- Safety & Reliability: Built-in safety protections (over-temperature, leakage protection) ensure operator and equipment safety.

V. Operating Steps

- Prepare test samples (standard size: 150 × 70 × 1–3 mm).

- Open the side panels and place samples evenly on the sample rack, securing them with spring clips to ensure uniform distance from the lamps.

- For small samples, fix them on opaque plates before mounting to prevent light/water leakage.

- Power on the required UV lamps.

- Close and secure the side panels.

- Verify the power connection and turn on the main power switch.

- Activate the control panel and operate via the interface.

- Calibrate irradiance using a handheld radiometer.

In summary, the UV Weathering Test Chamber is a vital tool for evaluating material weather resistance and reliability, with broad applications and significant advantages.