What Causes Insufficient Exhaust in the Compressor of a Walk-in High and Low Temperature Test Chamber?

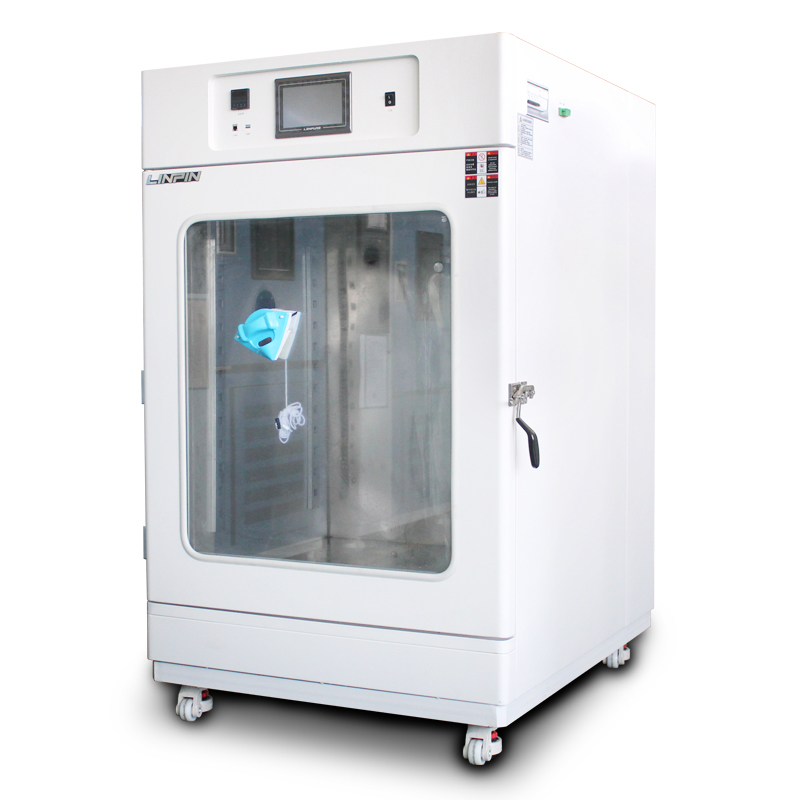

Author:LINPIN Update Time:2025-06-16 Source:LINPINA walk-in high and low temperature test chamber is a device used to evaluate the performance of materials, electronic products, automotive components, and other items under extreme temperature conditions. These chambers typically feature a large internal space, accommodating multiple or bulky test samples, making them suitable for large-scale or long-term environmental testing.

The main causes of insufficient compressor exhaust in a walk-in high and low temperature test chamber include the following:

Clogged Filter

After prolonged use, the filter may accumulate dirt and become blocked, reducing exhaust capacity. The solution is to clean or replace the filter.

Improper Suction Pipe Design

If the suction pipe is too long or has an excessively small diameter, it increases suction resistance, reducing intake volume and leading to insufficient exhaust. The solution is to optimize the pipe length and diameter.

Operation Beyond Specified Limits

Using the compressor in high-altitude areas or environments with significant temperature and humidity fluctuations can lower suction pressure and reduce exhaust capacity. The solution is to inform the manufacturer of the operating conditions before purchase to select a suitable compressor.

Component Wear

Severe wear of parts such as cylinders and pistons increases clearance and leakage, reducing exhaust capacity. The solution is to regularly inspect and replace worn components.

Valve Malfunction

Debris lodged between the valve seat and valve plate or aging valve plates can cause air leakage, affecting exhaust capacity. The solution is to clean out debris or replace worn valve plates.

Mismatched Valve Spring Force

If the valve spring force does not match the gas force, it can hinder proper valve plate movement, reducing exhaust capacity. The solution is to replace the spring with a suitable one.

Improper Tightening Force

Insufficient tightening force can cause air leakage, while excessive force may damage the valve cover. The solution is to adjust the tightening force appropriately.

By addressing these issues, the compressor's exhaust performance can be restored, ensuring the test chamber operates efficiently.