The Multiple Key Values of Ozone Aging Test Chambers

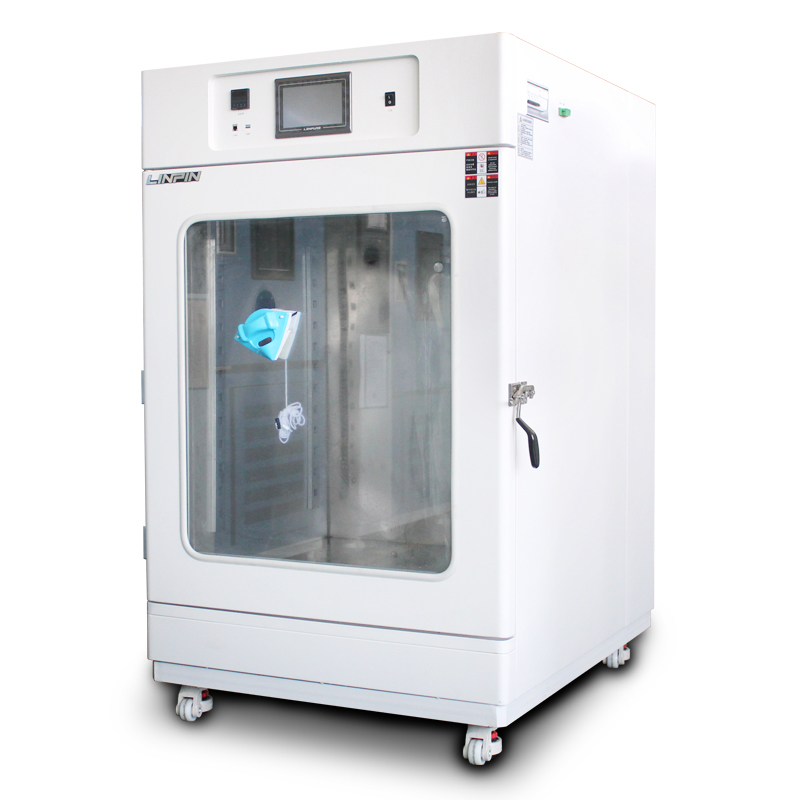

Author:LINPIN Update Time:2025-07-30 Source:LINPINThe ozone aging test chamber is a specialized device used to evaluate the ozone resistance of materials, widely applied in industries such as rubber, plastics, and coatings. Its multiple key values include:

1. Assessing Material Durability

By simulating ozone exposure, the test chamber evaluates how materials degrade over time, providing critical insights into their longevity and service life.

2. Quality Control

During production, the ozone aging test chamber helps inspect raw materials and finished products, ensuring compliance with industry standards and enhancing product reliability.

3. R&D Support

It provides essential data for developing new materials, allowing researchers to refine formulations and improve ozone resistance, accelerating the launch of innovative products.

4. Safety Evaluation

Industries with stringent safety requirements (e.g., automotive, aerospace) rely on ozone aging tests to assess material performance under extreme conditions, ensuring product safety.

5. Environmental Adaptability Testing

Since ozone is a common environmental pollutant, the test chamber simulates real-world exposure, helping manufacturers verify material resilience in ozone-rich environments.

6. Standardized Compliance Testing

The ozone aging test chamber adheres to international standards (e.g., ASTM, ISO), enabling companies to obtain certification data and enhance global market competitiveness.

7. Failure Analysis

By analyzing aged materials, manufacturers can identify failure causes, refine production processes, and select better materials to reduce defect rates.

8. Cost Savings

Early detection of ozone-induced degradation allows companies to make informed material and design choices, minimizing financial losses from premature failures.

The ozone aging test chamber plays a vital role in material evaluation, quality assurance, R&D, and safety testing, helping businesses maintain a competitive edge in demanding markets.