The Difference Between HAST Test Chambers and PCT Test Chambers

Author:LINPIN Update Time:2025-07-26 Source:LINPINIn the field of reliability testing for electronic components, materials, and related products, the use of various testing equipment has become increasingly common. Among them, HAST (Highly Accelerated Stress Test) chambers and PCT (Pressure Cook Test) chambers are two core devices. Although both aim to evaluate the durability and reliability of materials and components under specific environmental conditions, they exhibit significant differences. Below is a detailed comparison of the key distinctions between HAST and PCT test chambers to help you better select the appropriate testing equipment.

- Working Principles

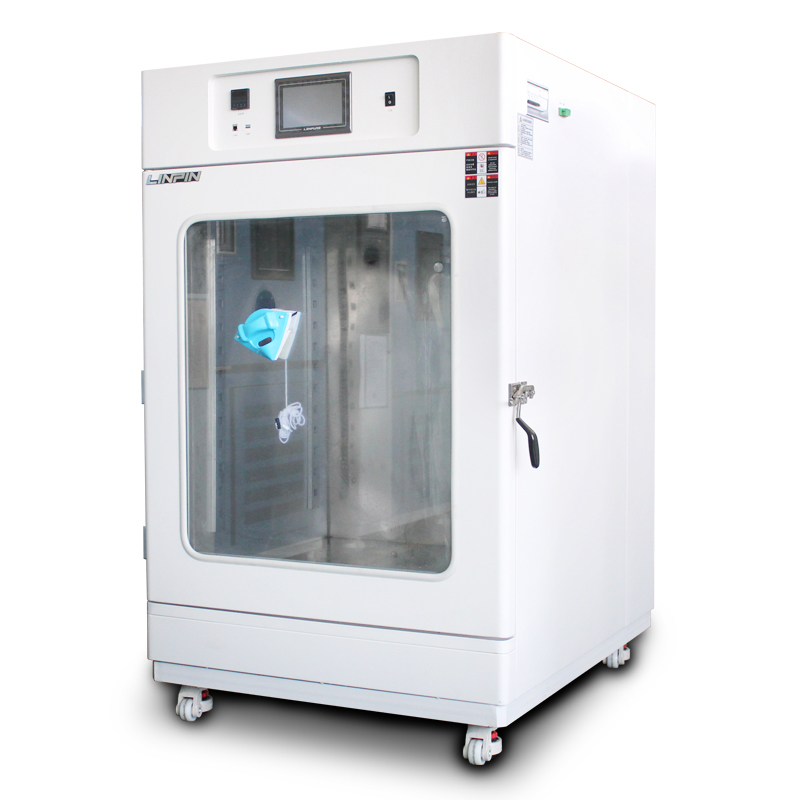

HAST test chambers primarily simulate material aging under high-temperature and high-humidity conditions. During testing, samples are placed in an environment with elevated temperatures (typically above 85°C) and high humidity (usually 85% relative humidity), accelerating the aging process to obtain reliability data in a shorter timeframe.

PCT test chambers, on the other hand, focus on simulating the effects of pressure and temperature variations on electronic components. By cyclically applying pressure (typically 2 atmospheres) combined with high-temperature and high-humidity conditions, PCT testing evaluates the integrity of packaging materials and seals, as well as product performance in extreme environments.

- Applicability

HAST test chambers are mainly used for testing humidity-sensitive electronic components, integrated circuits, LEDs, and related materials. The test results effectively assess product reliability in long-term humid environments, ultimately helping manufacturers improve product quality.

PCT test chambers are often employed for products that must withstand pressure variations, such as sealed components and high-performance materials. They help manufacturers identify potential reliability issues caused by poor encapsulation, ensuring product safety and stability in real-world applications.

- Testing Parameters

HAST test chambers focus on parameters such as high temperature, high humidity, and time, with relatively short testing cycles suitable for rapid evaluation and screening.

PCT test chambers involve more complex parameters, including temperature fluctuations, pressure cycles, and the number of cycles. The testing period is relatively longer, enabling in-depth assessment of material pressure resistance and long-term stability.

- Interpretation of Results

Test results from HAST chambers typically reflect material durability under high-humidity conditions, helping manufacturers refine product designs to reduce failure rates.

PCT chambers provide deeper insights into material lifespan and performance in extreme environments, identifying potential failure modes to guide improvements in the production process.

When choosing between HAST and PCT test chambers, companies must carefully consider product characteristics and required testing conditions. HAST chambers are suitable for rapid reliability testing in humid environments, while PCT chambers are better suited for complex evaluations involving pressure and temperature fluctuations. Understanding these differences can help manufacturers conduct product validation more effectively and enhance market competitiveness.