Smartphone Motherboard Programmable Temperature & Humidity Chamber Testing: How to Prevent Moisture-Induced Short Circuits?

Author:LINPIN Update Time:2025-08-16 Source:LINPINIn the fast-paced world of smartphone R&D and manufacturing, a stable and reliable motherboard is the foundation of every user experience. But have you ever considered how even the tiniest trace of moisture can undo millions of hours of meticulous design and debugging? An undetected humidity-induced short circuit could cause an entire batch of phones to fail after shipment, leading to massive recalls and brand damage.

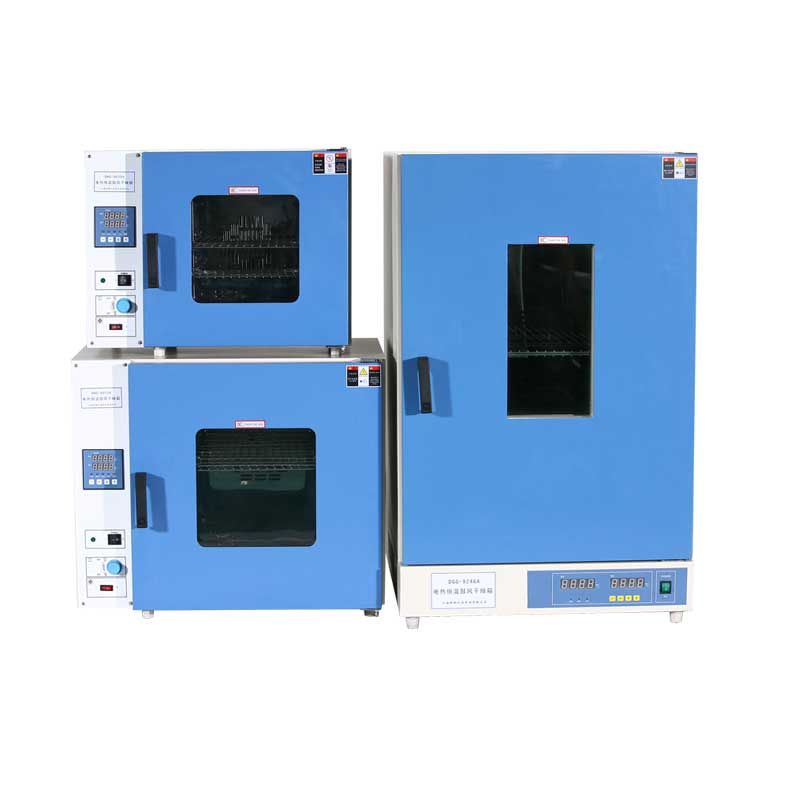

To safeguard quality and profitability, investing in a professional, intelligent programmable temperature and humidity test chamber for motherboard environmental testing is an essential "insurance policy" for every smartphone manufacturer and EMS provider. This article will break down how to scientifically prevent moisture-induced short circuits in constant temperature and humidity testing—covering equipment selection, testing procedures, and critical process details to help you minimize risks.

Why Are Temperature & Humidity Chambers Critical for Motherboard Testing?

- Simulates real-world conditions: These chambers accurately replicate high/low humidity, cyclic moisture exposure, and other real-life environmental stresses, exposing hidden vulnerabilities in motherboards under extreme conditions.

- Detects long-term reliability issues: Short-term functional tests often miss humidity-triggered failure mechanisms like electrochemical migration, corrosion, and insulation degradation. Accelerated testing uncovers these risks early.

- Ensures compliance & quality: Standardized, programmable testing meets stringent reliability requirements from clients and certification bodies, reducing recall risks.

How Does Moisture Cause Motherboard Short Circuits? Key Mechanisms Explained

- Surface Condensation: Sudden temperature drops or humidity spikes form conductive water films on the motherboard, bridging circuits.

- Ion Migration & Electrochemical Corrosion: Humidity dissolves electrolytes, enabling ion movement that creates conductive paths or corrodes solder joints.

- Hygroscopic Material Degradation: Absorbed moisture reduces dielectric strength in plastics/insulators, increasing leakage current and failure risks.

- Microcracks & Hidden Pathways: Moisture seeps into封装缝隙, causing internal shorts or intermittent connections.

Selecting the Right Programmable Chamber: Key Criteria

✔ Precision Control: Humidity stability (±1% RH) and temperature accuracy (±0.5°C) ensure test reproducibility.

✔ Programmability & Data Logging: Supports complex humidity/temperature profiles and real-time monitoring for traceability.

✔ Anti-Condensation Features: Rapid dehumidification, pre-cooling, and condensation prevention avoid uncontrolled moisture buildup.

✔ Optimized Chamber Design: Accommodates batch testing with proper airflow; fixtures must avoid obstructing critical components and ensure grounding.

✔ Corrosion-Resistant Materials: Chamber interiors and fixtures should resist long-term humidity exposure.

Testing Process & Best Practices to Mitigate Short Circuits

- Pre-Treatment: Pre-bake motherboards (e.g., 60°C for 2–4 hours) to reduce initial moisture content.

- Critical Area Protection: Shield connectors, exposed solder joints, and sensors with removable moisture barriers or conformal coatings (validate coating compatibility with test temps).

- Gradual Ramp Rates: Avoid abrupt temperature changes—program slow ramps and dwell times to minimize condensation.

- Cyclic Stress Testing: Implement multi-stage humidity/temperature cycles (e.g., high humidity + low-temperature condensation triggers) with intermittent electrical checks.

- Real-Time Monitoring & Fail-Safes: Continuously track current/voltage; cut power upon anomalies to prevent secondary damage.

- Post-Test Analysis: Dry boards immediately after testing, inspect electrical performance, and conduct failure analysis (microscopy, chemical tests) to identify root causes.

Material & Process Improvements for Moisture Resistance

- Conformal Coatings: Apply polyurethane, silicone, or acrylic coatings to critical areas (verify impact on signal integrity/thermal performance).

- Enhanced Sealing: Improve connector gaskets, solder mask coverage, and component placement to eliminate moisture traps.

- Low-Hygroscopic Materials: Select PCB substrates, capacitors, and connectors with minimal moisture absorption.

- Ventilation & Desiccants: Integrate密封圈, desiccant compartments, and airflow paths to prevent moisture accumulation.

Case Study & ROI

- Success Story: A smartphone manufacturer reduced moisture-related motherboard failures by over 70% after adopting precision programmable chambers with pre-baking and real-time monitoring, slashing recall risks and customer complaints.

- ROI: Compared to the astronomical costs of recalls or batch rework, investments in proper testing equipment and process upgrades typically pay for themselves within a year.

Moisture is silent but deadly—capable of crippling precision electronics when least expected. For smartphone brands, embedding reliability into every design and test cycle is a non-negotiable commitment to users and reputation. By deploying high-performance programmable chambers, implementing rigorous pre-test protocols and real-time monitoring, and continuously refining materials and封装工艺, you transform invisible threats into quantifiable data—ensuring every motherboard withstands the test of time and environment.