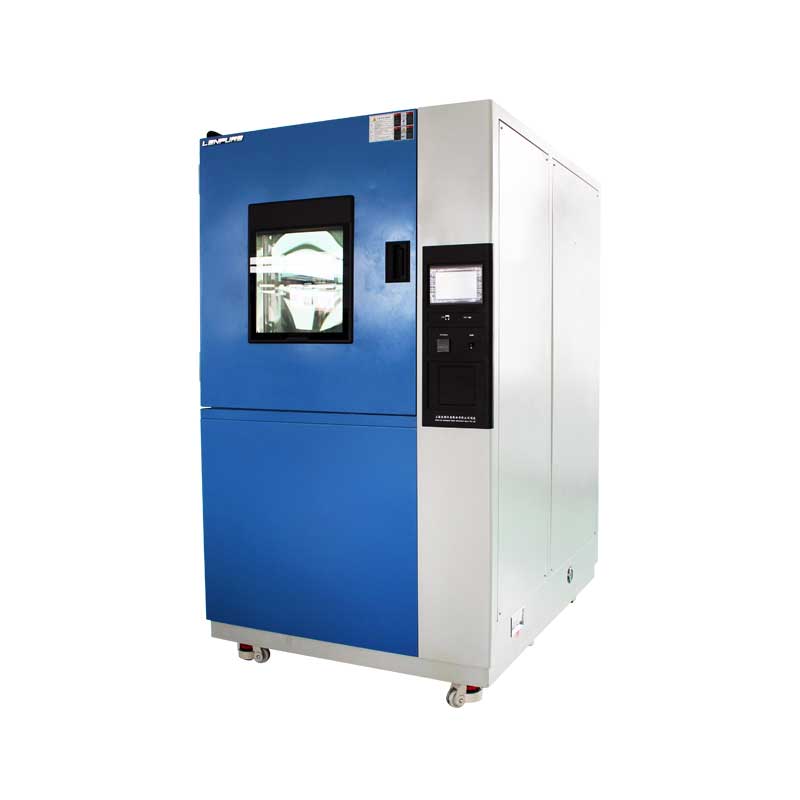

High-Precision Thermal Vacuum Test Chamber: Unlocking Infinite Possibilities for Product Testing

Author:LINPIN Update Time:2025-05-30 Source:LINPINThe high-precision thermal vacuum test chamber is a device designed to simulate extreme temperature and vacuum environments, opening up limitless possibilities for product testing. It plays a crucial role in various fields, including aerospace, electronics, materials science, and manufacturing.

The thermal vacuum test chamber provides highly accurate temperature control, capable of simulating a wide range from ultra-low to extremely high temperatures. This is essential for evaluating product performance and reliability under different thermal conditions. For example, in the aerospace industry, spacecraft must operate reliably in the extreme cold of space or the intense heat of atmospheric re-entry. By using a thermal vacuum test chamber, these harsh conditions can be replicated to ensure product dependability in real-world applications.

Additionally, the thermal vacuum test chamber can create a vacuum environment, simulating high-altitude, space, or other vacuum conditions. In many electronics and materials applications, vacuum conditions significantly impact product performance and stability. Testing in a thermal vacuum chamber allows manufacturers to assess product behavior in such environments and make necessary improvements and optimizations.

The thermal vacuum test chamber also features precise temperature and pressure control, enabling accurate simulation of temperature and pressure gradients. This is invaluable for replicating complex operational conditions and studying their effects on product performance. For instance, in materials research, scientists can test the physical and chemical properties of materials under varying temperature and pressure conditions to better understand their behavior and characteristics.

The thermal vacuum test chamber unlocks infinite possibilities for product testing. It can simulate extreme temperature and vacuum conditions to evaluate product performance and reliability across different environments. By utilizing this advanced testing solution, manufacturers can enhance product quality and dependability while gaining valuable data and insights to guide research, development, and refinement.