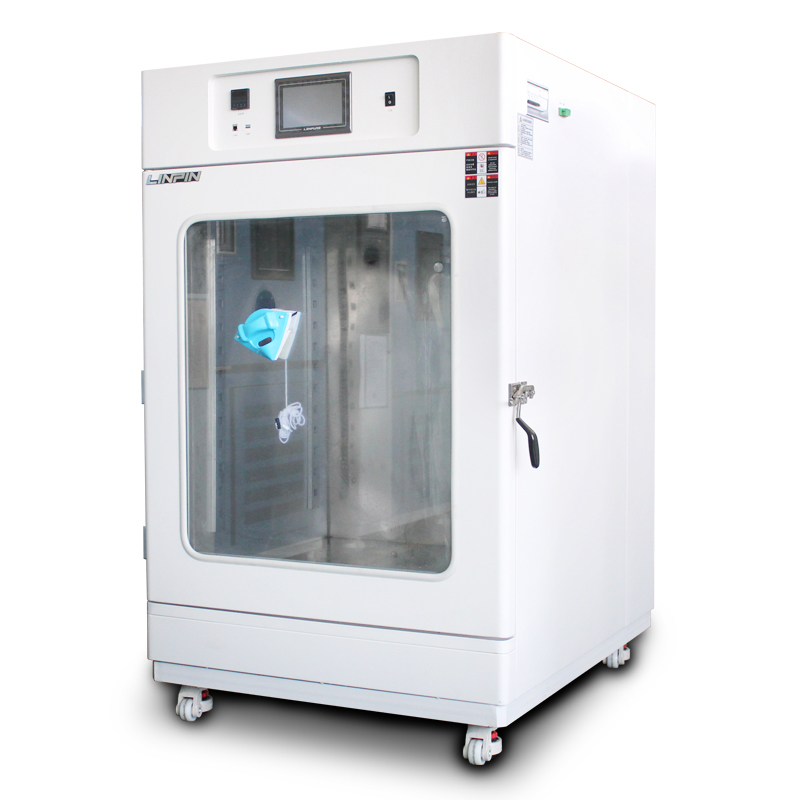

Complete Guide to High and Low Temperature Humidity Alternating Test Chambers

Author:LINPIN Update Time:2025-05-26 Source:LINPINIn modern industrial production and scientific research, product reliability and durability have become key factors in ensuring market competitiveness. The high and low temperature humidity alternating test chamber, as a high-precision device that simulates extreme environmental conditions, is increasingly becoming an indispensable tool for testing product performance in industries such as electronics, electrical appliances, automotive, aerospace, and materials.

I. Introduction to High and Low Temperature Humidity Alternating Test Chambers

A high and low temperature humidity alternating test chamber is an environmental testing device capable of simulating high temperature, low temperature, and alternating humidity conditions. By setting periodic changes in temperature and humidity, it replicates various climatic environments that products may encounter in real-world use, thereby evaluating their adaptability and service life.

II. Working Principle and Functional Features

Working Principle:

The device achieves rapid temperature transitions through an internal refrigeration and heating system, while the humidity system controls air moisture via a humidification device. Programmable controls enable alternating temperature and humidity variations.

Functional Features:

- Wide temperature range, typically from -70°C to +150°C.

- Precise humidity control, usually within 20%–98% RH.

- Multi-stage program control, allowing customized temperature and humidity change curves based on testing needs.

- High-efficiency insulation materials ensure stable testing conditions and energy savings.

- Intelligent control system supports remote monitoring and data logging.

III. Applications

- Electronic component testing: Evaluates the stability of electronic products under fluctuating temperature and humidity conditions.

- Automotive component aging tests: Simulates long-term climate exposure to assess part durability.

- Aerospace materials: Tests material deformation and performance under extreme environments.

- Environmental adaptability tests for plastics, rubber, and other materials.

- Food packaging and pharmaceutical product stability studies.

IV. Key Considerations When Selecting a Test Chamber

- Temperature and humidity control accuracy: High precision directly impacts test result reliability.

- Chamber size: Choose an appropriate volume based on product dimensions.

- System stability and safety: Multiple protective measures are essential for safe operation.

- Brand and after-sales service: Opt for reputable brands with strong support to minimize risks.

V. Standards for High and Low Temperature Humidity Alternating Test Chambers

Common standards for these test chambers cover performance, testing methods, and environmental conditions, including:

- GB/T 2423.1-2008: Environmental Testing for Electric and Electronic Products – Part 2: Test Methods – Test A: Low Temperature Test

- GB/T 2423.2-2008: Environmental Testing for Electric and Electronic Products – Part 2: Test Methods – Test B: High Temperature Test

- GB/T 2423.3-2006: Environmental Testing for Electric and Electronic Products – Part 2: Test Methods – Test Ca: Damp Heat, Steady State

- GB/T 2423.4-2008: Environmental Testing for Electric and Electronic Products – Part 2: Test Methods – Test Db: Damp Heat, Cyclic

Additionally, industry-specific or corporate standards may apply depending on testing requirements.

Conclusion

With its unique ability to simulate real-world conditions and validate product quality, the high and low temperature humidity alternating test chamber has become an essential testing asset across multiple industries. Selecting the right chamber not only enhances product quality but also strengthens market competitiveness. Whether for R&D or quality control, this device is an ideal choice for your needs.