Communication Equipment Extreme Performance Testing: High and Low Temperature Alternating Test Chambers Drive Industry Innovation

Author:LINPIN Update Time:2025-07-15 Source:LINPINIn the research, development, and production of communication equipment, ensuring stability and reliability under extreme environmental conditions is critical. As a key testing device, high and low temperature alternating test chambers provide robust support for innovation and advancement in the communication industry. Below, we explore how these test chambers facilitate extreme performance testing for communication equipment and their role in driving industry innovation.

-

The Importance of High and Low Temperature Alternating Test Chambers

High and low temperature alternating test chambers are experimental devices that simulate environmental temperature variations, enabling the testing and validation of product performance under alternating high and low-temperature conditions. Such equipment is particularly vital for communication devices, as they often need to operate reliably in extreme temperatures, such as scorching deserts or freezing polar regions. By using these test chambers, manufacturers can simulate these harsh conditions to ensure the reliability and durability of communication equipment in real-world applications.

-

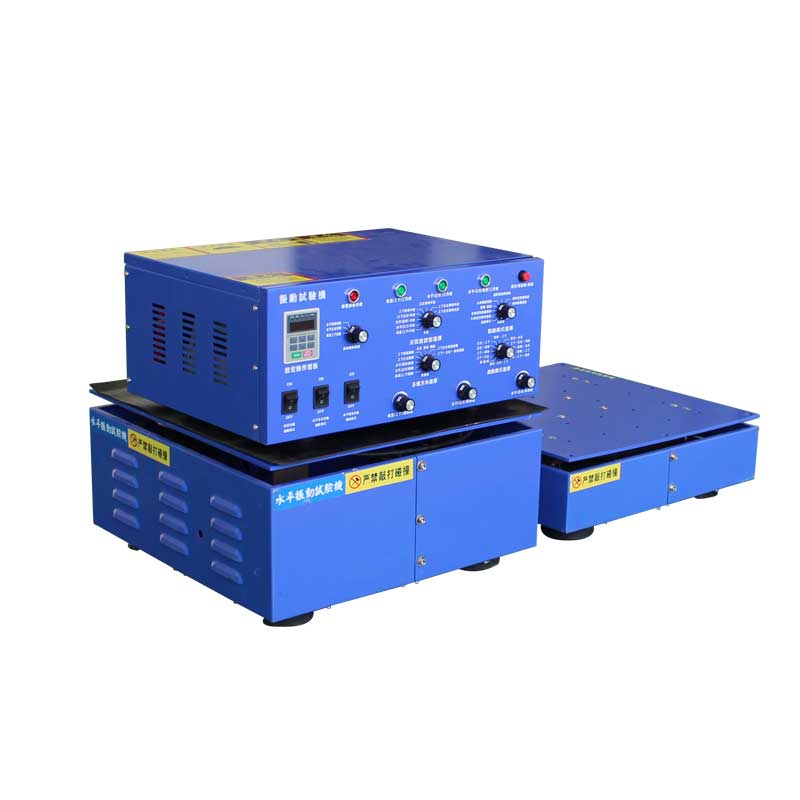

Working Principles and Structural Features

High and low temperature alternating test chambers achieve alternating cycles of high and low temperatures within a set range by controlling cooling and heating systems. Their structure typically includes a sealed chamber with high-temperature and low-temperature resistance, a refrigeration system, a heating system, and an advanced control system. These components work in synergy to precisely regulate temperature fluctuations and change rates inside the chamber, simulating real-world environmental temperature variations. -

Applications in the Industry

High and low temperature alternating test chambers are widely used in the communication industry. They are employed not only to test the physical performance of communication equipment—such as material temperature resistance and changes in electronic component performance—but also to evaluate overall device performance, including signal transmission, data processing, and power management. Through these tests, manufacturers can ensure that communication equipment maintains optimal performance even under extreme temperatures. -

A Driving Force for Industry Innovation

With rapid technological advancements, performance testing plays a crucial role in ensuring system stability, reliability, and efficiency. As an essential tool for performance testing, high and low temperature alternating test chambers not only help communication equipment manufacturers identify and resolve potential issues but also promote the development and application of new technologies and materials. For example, extreme testing can reveal performance bottlenecks, thereby driving the formulation and implementation of optimization strategies.

High and low temperature alternating test chambers are indispensable tools for extreme performance testing of communication equipment. By simulating extreme environmental conditions, they help manufacturers ensure product reliability and stability. As communication technology continues to evolve, these test chambers will remain pivotal in fostering industry innovation and driving continuous improvements in communication equipment performance.