Can You Replace a Broken Sensor in a Thermal Shock Test Chamber Yourself?

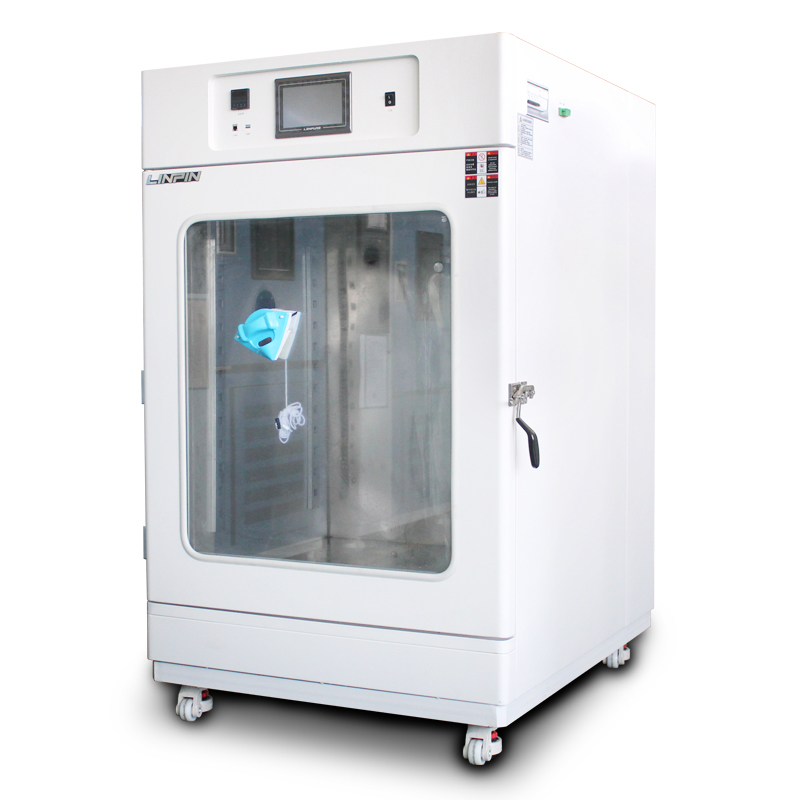

Author:LINPIN Update Time:2025-08-13 Source:LINPINIn the context of rapid technological advancements, various testing equipment plays a crucial role in industrial production and scientific research. Among them, thermal shock test chambers are essential for evaluating the performance of materials and products. However, with prolonged use, the sensors in these chambers may malfunction. So, can you replace them on your own?

Replacing a sensor in a thermal shock test chamber requires specialized knowledge and operational skills, making it not recommended for self-replacement. Below are the key reasons and precautions:

1. Operational Risks

- Sensor replacement involves circuit debugging and precision calibration. Improper handling may lead to equipment damage or inaccurate test data.

- For example, after replacing a temperature sensor, PID parameters must be reconfigured and recalibrated—otherwise, temperature control accuracy may be compromised.

2. Tool Requirements

- Specialized tools such as a multimeter (for checking circuit continuity and resistance values), screwdrivers, and socket wrenches are necessary.

- Inexperienced handling may damage the equipment or pose an electric shock hazard.

3. Recommended Solutions

- Contact the manufacturer or professional technicians: Since sensor replacement involves critical components, it is best to rely on the manufacturer or certified repair teams to ensure proper maintenance.

- Refer to the user manual: If self-replacement is unavoidable, thoroughly read the sensor replacement procedure in the equipment manual and strictly follow the steps.

While it might be tempting to attempt a DIY fix, sensor replacement in a thermal shock test chamber is a delicate task best left to professionals to avoid costly mistakes and ensure optimal performance.